You could keep an eye out for one of these:Just picked up my mill and need to figure out how I'll going to power it.

I was lucky and picked this one up for $15 at a Recycle Tip while looking for a transformer to make a Styrofoam cutter.

To switch the power from AC to DC I bolted the ZR-1324 Bridge Rectifier onto the side (about $6 from Jaycar) and Bob's your auntie.

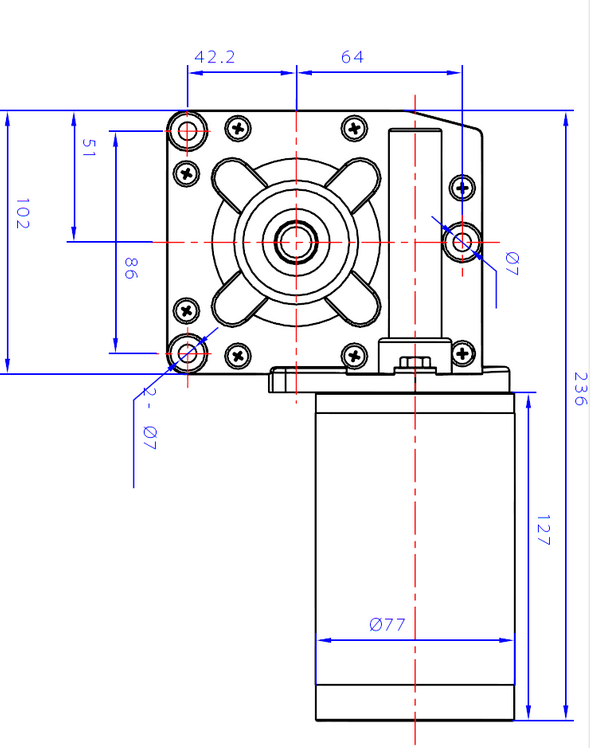

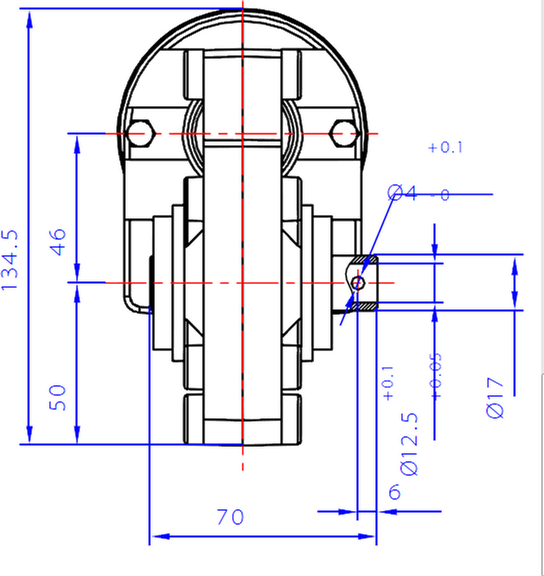

Because the MashMaster 1 Mill is such a big brute I got the bigger SC450G geared motor from Oatley Electronics instead of the SC250G but then needed plenty of amps to power it.

They're are similar transformers to this around so you might want to keep an eye out for one that might suit your setup. Until I found mine I just wheeled the mill to the car & used its battery.