Yob

Hop to it

Ha.. yeah cheers, today was a piece of piss.. the 6 months of research, building and tweaking was a curve though

It 's a simple tee piece with a terminator end. I epoxied it in there using high temp expoxy.

Looks a lot tidier mate... Go on.. Give it a wet run

Looks Great Truman. I wish that I had the room for a nice tidy setup like that - as it is, At the moment I have to drag everything out of storage when I want to brew.

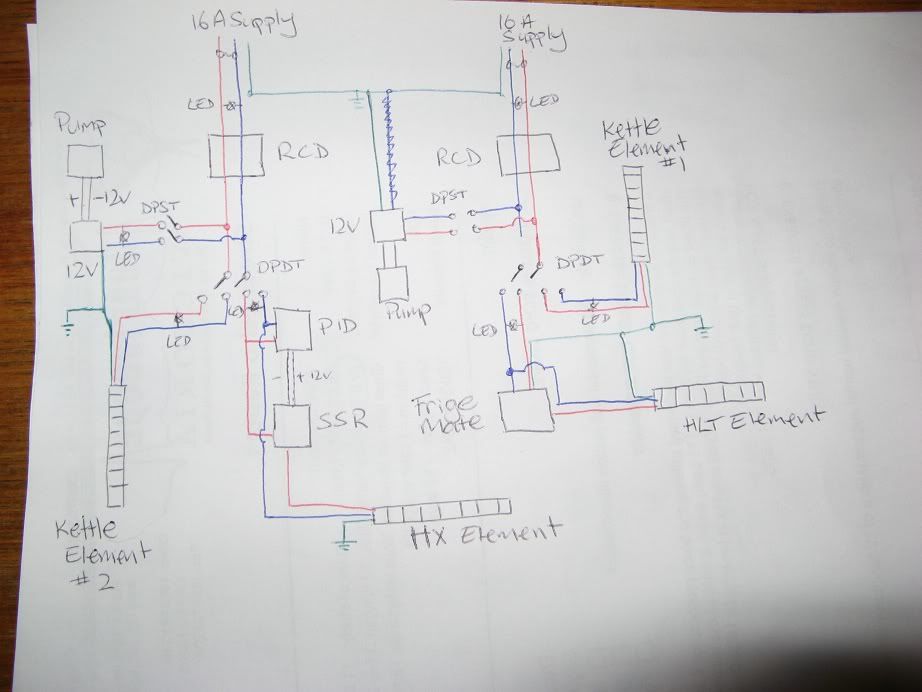

It makes it neat by mounting the pump switch in the frame, although if you haven't already, you should probably earth the frame of your stand, or at least run your pump off a Safety Switch.

If any water gets on the back of that switch, it could light the whole frame like a christmas tree!

I dont get how your hook holds the element though? Wont the lid be in the way??

Nice one! But... it looks like you've taped the lid on? Isn't that going to be problematic? Am I right in thinking this unit is your combined HLT/HEX?

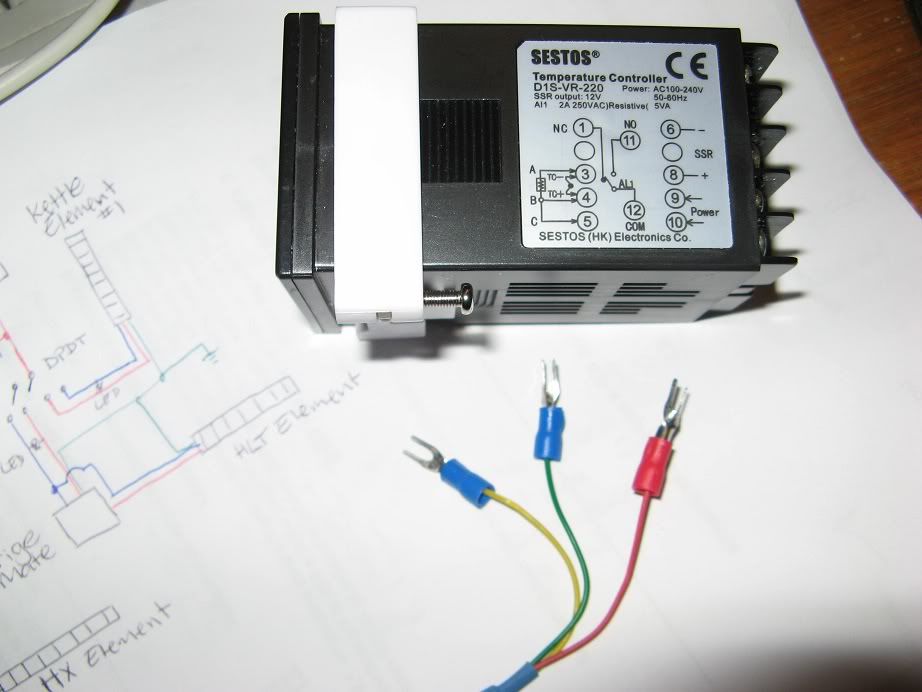

... is that I simply press the AT key (for 2 seconds) and then something visible should happen.3/ First operate the Auto adjustment, press AT key 2 second, SV display blink AT, finally into PID control mode. Press the AT key 2 second to abandon Auto adjustment.

4/ If successful the first Auto adjustment, can not use AT key for Auto adjustment again. It need change function setting Ctrl to 2 to operated again.

5/ Auto adjustment needs from few second to few hour.

Has anyone had success with auto-tuning the Sestos D1S-VR-220 PID?

My understanding of the instructions:

... is that I simply press the AT key (for 2 seconds) and then something visible should happen.

But pressing the AT key seems to do nothing that I can see, but assistance translating the instructions to someone who has used it successfully would be appreciated.

Yep the Auber instructions were invaluable for changing the probe-type-setting, no way I'd have accomplished that with the Sestos stuff, so I might have to read them again.I've just received 2 of these that I'm yet to power on, so can't help, I'm afraid, but would be very interested in any advice about these devices. There should be a way to set the "control output" function to "auto adjustment" (the other 2 choices being "ON/OFF" and "PID"). So maybe you'll have to manually kick off the process that way.

A few folks have reported that these units are so similar internally to the Auber ones that the manual is more or less interchangeable (although the contact layout is completely different).

Enter your email address to join: