djar007

Well-Known Member

I've got a temp probe that's brand new you can have mate. Looks the same size. It's the One with weld less already part of it. Regards dave

http://www.ebay.com.au/itm/RTV-650F-Red-Silicon-Adhesive-FDA-Food-Grade-Safe-High-Temp-Gasket-smoker-sealer-/171054621766?pt=LH_DefaultDomain_0&hash=item27d3a66446tateg said:Hi guys

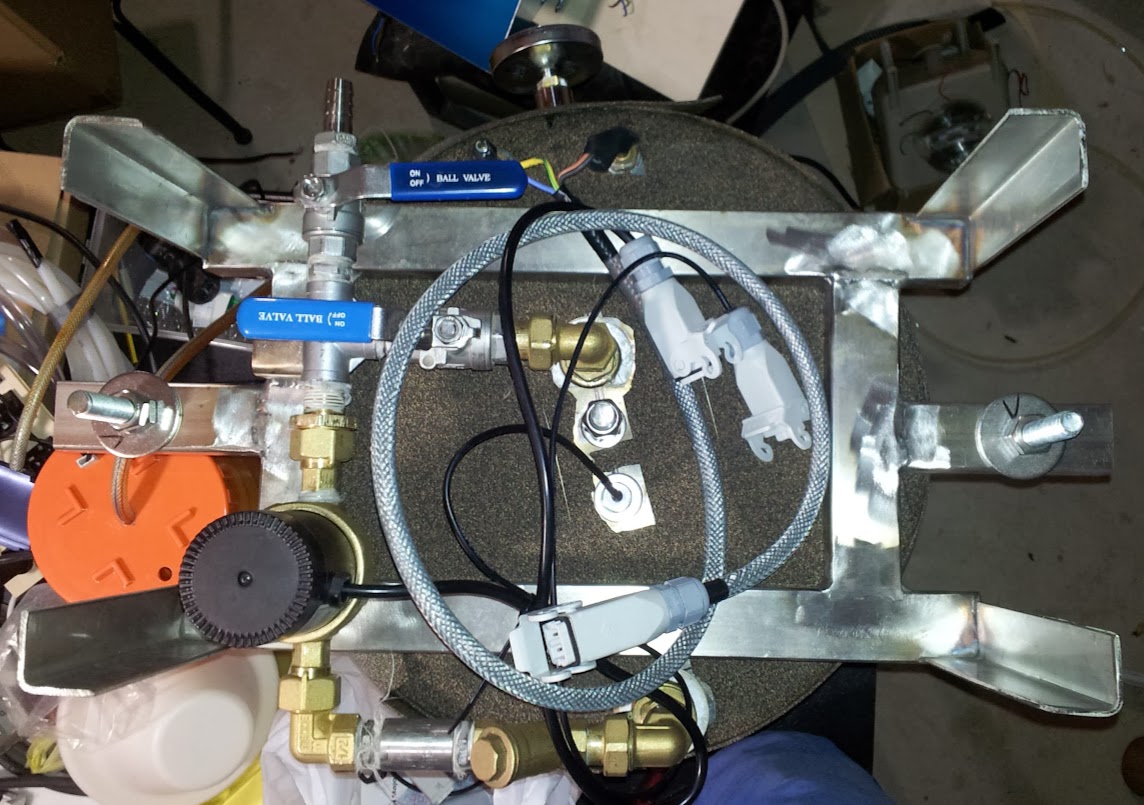

I am looking for a food grade epoxy to seal up the thermowell in the pics below, would need to be more of a liquid I think.

Could I use jb weld? Haven't been able to find a definitive answer if it is beer safe

Cheers

ImageUploadedByAussie Home Brewer1385944587.078875.jpg ImageUploadedByAussie Home Brewer1385944607.026776.jpg

ImageUploadedByAussie Home Brewer1385944607.026776.jpg

Not yet, I ordered some on the weekend to seal a leaky seam on my malt-pipe so it will be a week or so before it gets here.tateg said:Thanks have you tried the stuff??

Enter your email address to join: