You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Matho's controller

- Thread starter MastersBrewery

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

claudiobr74

Member

That was what I did! I have used 98°C and boiling was great but the counter didn't start, once never passes 97,5°C. And when I tried 97°C the boiling became weak. That is the reason I want made this firmware change. I believe that is not a hard work, but my arduino skils are limited.

claudiobr74

Member

.

claudiobr74 said:That was what I did! I have used 98°C and boiling was great but the counter didn't start, once never passes 97,5°C. And when I tried 97°C the boiling became weak. That is the reason I want made this firmware change. I believe that is not a hard work, but my arduino skils are limited.

My method may not be the best as it does need manual input, but I find it works for me. What I do is leave it at the original 98c (in your case set to 97c) so it triggers the boil timer, but it is not hot enough for a potential boil over. Once it starts timing I then use the up arrow to set the temperature to 111c so the element stays on 100% duty, and I can monitor for a boil over. I also have it set to a 70min boil, rather than 60min to allow the extra time to get to a full clean rolling boil.

MastersBrewery

Journeyman, the learning never stops

- Joined

- 7/6/11

- Messages

- 2,319

- Reaction score

- 683

The counter is an entirely different problem.

what code are you using ? Matho's original code ? or ArdBir ? and what version?

what code are you using ? Matho's original code ? or ArdBir ? and what version?

claudiobr74

Member

I'm using the last firmware (v10). There's no problem with the counter. It works fine. It didn't start because the temperature never reaches 98°C.

claudiobr74

Member

Thats a great idea! How didn't think this. It certainly has the manual incovenient but it is a solution for now.QldKev said:My method may not be the best as it does need manual input, but I find it works for me. What I do is leave it at the original 98c (in your case set to 97c) so it triggers the boil timer, but it is not hot enough for a potential boil over. Once it starts timing I then use the up arrow to set the temperature to 111c so the element stays on 100% duty, and I can monitor for a boil over. I also have it set to a 70min boil, rather than 60min to allow the extra time to get to a full clean rolling boil.

Cheers

I've been looking at upgrading my pump to a 240v pump. Am I right in looking at the wiring diagram in the Brauduino that it can switch 240v directly? Just run a live to one pump terminal on the pcb then the other terminal to the pump, directly wire the neutral and make sure it's grounded?

Pirate323i

Well-Known Member

- Joined

- 20/5/14

- Messages

- 49

- Reaction score

- 11

Hi Max,MaxN68 said:Why did you change the code?

Beware that there are so many variable that influence the system on several occasions corertto operation of the entire firmware

I changed the code as I could not get the temperature to read... It merely said 0.0*C I suspect it is an issue with my temp sensor because Matho's code did not work either. I first got it to work by pasting in the code from the OneWire example. however I then further reduced the coding by calling the Dallas Library and it uses about 3 lines of code. I also had to change the pin for temp reading as for some reason my pin 11 does not work on my Arduino... I have wired it to pin A5 (not used on the Brauduino shield) and added my 4k7 resistor external to the board.

I certainly appreciate all the work that has gone into this code by all the contributors! Now I just need to get my physical build finished so I can start brewing!

MaxN68

Well-Known Member

The difference of code between Brauduino and ArdBir on the reading of the temperature is in the use of a 9-bit bus vs. 2 bits for error control of reading (probe not inserted reads 0 ° C)

For a more precise reading should be added to the library Dallas but this takes up too much space and I do not believe that the benefits are considerable. It would be very different if you were using multiple probes because the library Dallas allows the management of multiple sensors in parallel

For a more precise reading should be added to the library Dallas but this takes up too much space and I do not believe that the benefits are considerable. It would be very different if you were using multiple probes because the library Dallas allows the management of multiple sensors in parallel

I managed to get my kit put together today however managed to get a few transistors around the wrong way (display was scrambled with only AC in live). When trying to de-solder I managed to burn the board and the little metal ring that you solder the transistors to came off. I'm not sure how to solder the transistors back in now!

Can it be saved or do I have to get another board and de-solder everything (this time properly with a pump).

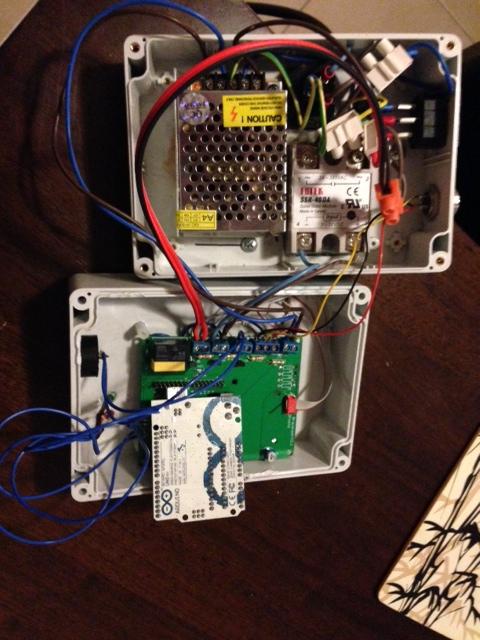

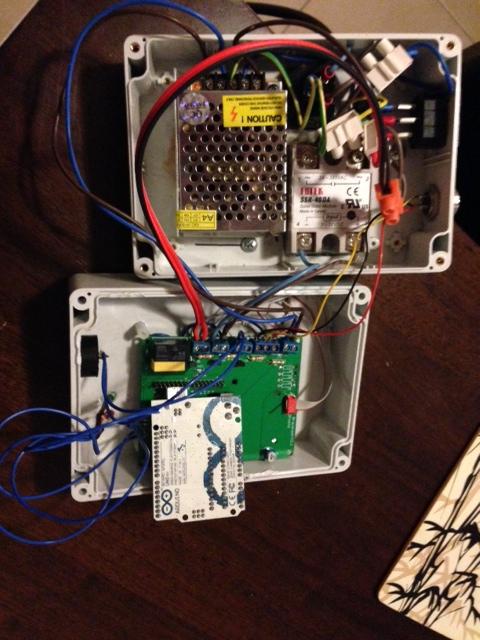

excuse the dog breakfast of cabling it will all be secured once I know everything is working.

Can it be saved or do I have to get another board and de-solder everything (this time properly with a pump).

excuse the dog breakfast of cabling it will all be secured once I know everything is working.

MaxN68

Well-Known Member

in the next few days will be published version 2.6.70 with some minor new features useful in complete automation of the process and a small utility in manual mode

eresh666 said:I managed to get my kit put together today however managed to get a few transistors around the wrong way (display was scrambled with only AC in live). When trying to de-solder I managed to burn the board and the little metal ring that you solder the transistors to came off. I'm not sure how to solder the transistors back in now!

Can it be saved or do I have to get another board and de-solder everything (this time properly with a pump).

excuse the dog breakfast of cabling it will all be secured once I know everything is working.

It's not promising. You can try adding a little solder on both sides of the board where the resistors go in and see how it goes.

All you need to do is determine the intended connections at the node where the broken pad is (from schematic), and reconnect the resistor pin to the nearest place (other component pin, pad, or via) where it can reestablish the original connection points. Do this by soldering some very small gauge wire to recreate the connections. Good luck...

Pirate323i

Well-Known Member

- Joined

- 20/5/14

- Messages

- 49

- Reaction score

- 11

I agree, get some insulated wire and jumper from the resistor to where it is connected... That is bypass the board. These resistors are external pull-up resistors for the buttons, and should not effect how the screen displays.. It is possible that your 240v wiring is affecting the screen. Cavemanbrew had a similar problem. I believe it was a matter of tidying the wiring that fixed the problem.

Good luck!

Good luck!

Smokomark

Well-Known Member

- Joined

- 30/9/11

- Messages

- 536

- Reaction score

- 93

I finally got around to putting together my Matho / Bonj circuit boards over the last couple of weeks. Idid the box and 240 side well over a year ago.

On powering up everything looks good, temp displaying ok. I can go into setup and enter my mash and hop schedule. In fact everything seems fine except one thing. The start button does nothing. I have replaced the button and gone over both boards and resoldered every connections.

Any suggestions where to go from here?

On powering up everything looks good, temp displaying ok. I can go into setup and enter my mash and hop schedule. In fact everything seems fine except one thing. The start button does nothing. I have replaced the button and gone over both boards and resoldered every connections.

Any suggestions where to go from here?

Hi Smokomark

Do you have a volt meter or resistance meter?

Power off ansd unplug from wall

Un plug the arduino.

Measure from ground side of switch to the gnd connection to 12v supply. Should be close to 0 ohms

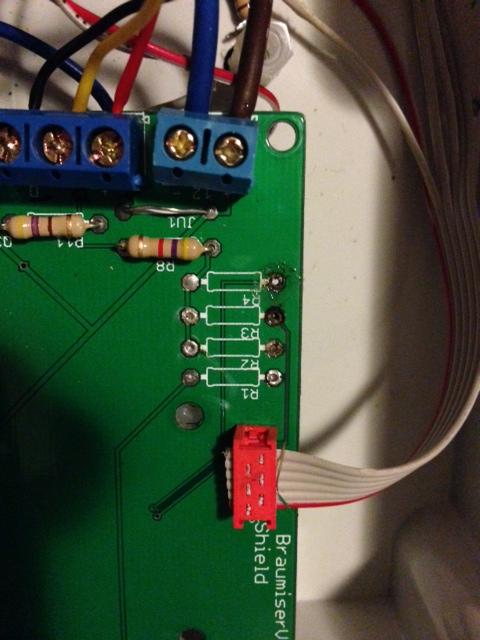

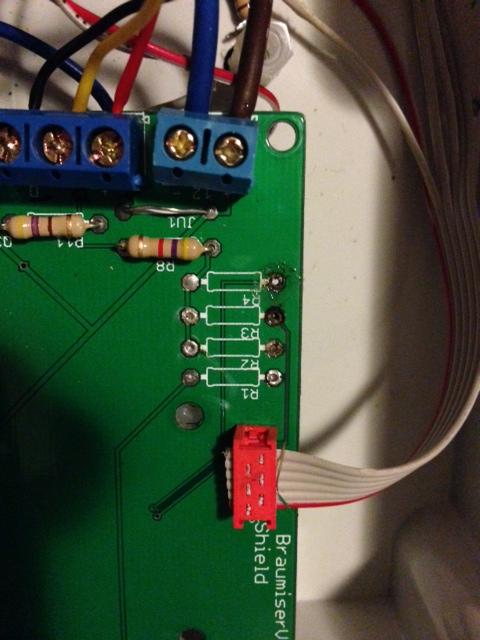

Measure other side of switch to resistor R1. Should be close to 0 ohms one end of resistor and 10,000 (10k) the other end. It should also be close to 0 ohms from same side of switch to pin 1 of J8 connector to arduino.

You could compare with one of the other switches. Like next switch and R2 and pin 2 of J8

Probably check the value of the resistors and that arduino plugs in correctly.

And that if you programmed arduino that you selected correct board type and display type etc.

Zwitter

James

Sent from my iPad using Tapatalk HD

Do you have a volt meter or resistance meter?

Power off ansd unplug from wall

Un plug the arduino.

Measure from ground side of switch to the gnd connection to 12v supply. Should be close to 0 ohms

Measure other side of switch to resistor R1. Should be close to 0 ohms one end of resistor and 10,000 (10k) the other end. It should also be close to 0 ohms from same side of switch to pin 1 of J8 connector to arduino.

You could compare with one of the other switches. Like next switch and R2 and pin 2 of J8

Probably check the value of the resistors and that arduino plugs in correctly.

And that if you programmed arduino that you selected correct board type and display type etc.

Zwitter

James

Sent from my iPad using Tapatalk HD

Pirate323i

Well-Known Member

- Joined

- 20/5/14

- Messages

- 49

- Reaction score

- 11

It could also be an issue with the arduino board... None of the buttons worked with my "arduino uno clone" and I had issues with pin 11 on my "etherten" board (solved by rewiring to pin A5)...

Good luck!

Good luck!

MaxN68

Well-Known Member

version 2.6.70

MANUAL MODE: You can switch the timer in a countdown acting simultaneously on buttons START + ENTER and setting the time with the UP and DOWN buttons. Repressing START + ENTER to activate the countdown

SET PID: was placed the duration of the sampling cycle to 3500ms and rescaled the value of kI (0.25) in order to have a more precise control of this constant.

During configuration must be rescaled by multiplying the old value by 4.

SET UNIT: two configurations have been added that allow you to check the status of Remove Malt and Iodine Test.

- Remove Malt: you can set the temperature control (ON/OFF) only to systems with internal temperature sensor

- Iodine Test: You can set the maximum execution time of the extra time (max 90 min) after which the system automatically advances to the next step; it is always possible to manually move forward step.

Setting the time to 0 min (OFF) user intervention is required for the advancement of the step.

CAUTION: For proper operation, proceed to configure the unit in its entirety before you perform any of the brewing cycle.

MANUAL MODE: You can switch the timer in a countdown acting simultaneously on buttons START + ENTER and setting the time with the UP and DOWN buttons. Repressing START + ENTER to activate the countdown

SET PID: was placed the duration of the sampling cycle to 3500ms and rescaled the value of kI (0.25) in order to have a more precise control of this constant.

During configuration must be rescaled by multiplying the old value by 4.

SET UNIT: two configurations have been added that allow you to check the status of Remove Malt and Iodine Test.

- Remove Malt: you can set the temperature control (ON/OFF) only to systems with internal temperature sensor

- Iodine Test: You can set the maximum execution time of the extra time (max 90 min) after which the system automatically advances to the next step; it is always possible to manually move forward step.

Setting the time to 0 min (OFF) user intervention is required for the advancement of the step.

CAUTION: For proper operation, proceed to configure the unit in its entirety before you perform any of the brewing cycle.

Similar threads

- Replies

- 13

- Views

- 4K

- Replies

- 12

- Views

- 3K

- Replies

- 11

- Views

- 5K

- Replies

- 26

- Views

- 9K