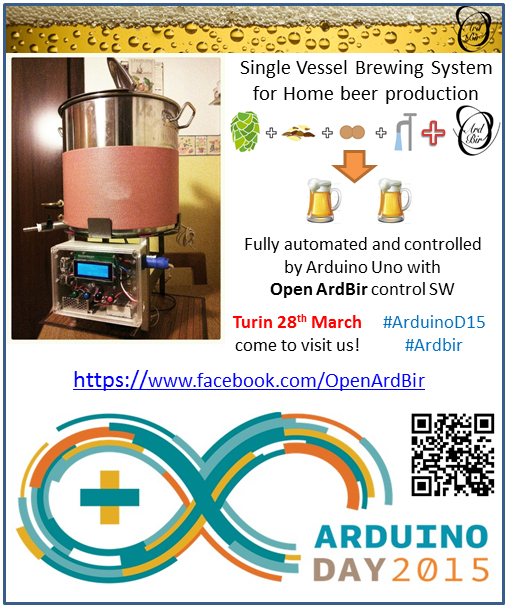

Opne ArdBir and the single vessel brewing system have been selected for Arduino Day 2015 event

very proud of this and may thanks to all people in this form that contributed to this project

you can follow the event in live streaming and on twitter #Ardbir #ArduinoD15

https://youtu.be/sGCiiL0JQ5s

stay tuned!

Davide

very proud of this and may thanks to all people in this form that contributed to this project

you can follow the event in live streaming and on twitter #Ardbir #ArduinoD15

https://youtu.be/sGCiiL0JQ5s

stay tuned!

Davide