Long time no post, but there has been quite some progress.

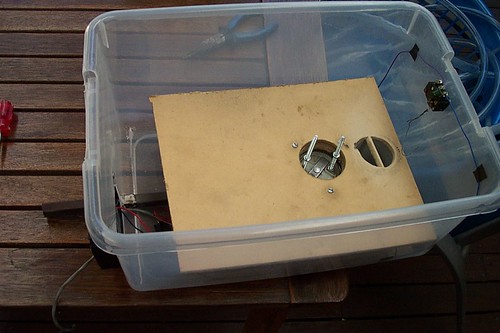

To solve the hop dropper problems with steam I wanted to enclose it in a case a have a small fan pressurise it. So I got a cheap plastic box and built a new dropper setup out of some scrap MDF and one of my wiper motors.

A while back it pissed down and poor old brewbot was wet for week out on the deck. It started to rust.

So I was force to paint him.

While stripped down, the brain got an upgrade to a set of 4 triacs with opto-isolators I had laying around. To fit them in with PCB & heatsink, I had to move the CPU board & transformer.

I have not moved the heating element control over to triacs yet. But the pump is on a triac, and I have another set aside for running a HERMS element. For those not in the know, a triac the main component of a Sold State Relay. It will allow my to drive the 240v get at a variable duty cycle, like a dimmer.

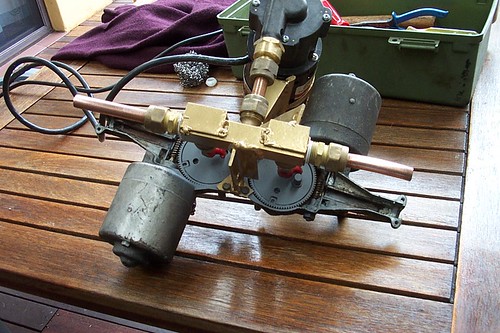

I also spent a lot of time tracking down some issues with driving the wiper motors.

The problem was that the CPU would sometimes reset when changing the valves. Or sometimes it would latch up hard, with only a power reset bringing things back. So I wrote a little test harness to cycle the valves. It would only survive a few iterations, so it was quick to test attempted fixes.

I was pretty sure it was a hardware problem. First stop was some more filter caps on the power supply. No change. Then a zener diode and filter cap on the motor-stall current sense circuit. No change. Then I tried disconnecting the current sense circuit. No change. Then I tried shorting out all the motors to prove it wasn't a power supply glitch. The test would run indefinitely proving that the power supply had no trouble delivering the current needed: the problem was clearly due to the inductive nature of the load.

I couldn't see why the CPU was having trouble. I tried running it from a separate power supply, but still the resets were happening. Finally I found a bipolar electrolytic in the junk box and put that across one of the motors. Problem solved. On the CRO I could now see the spike. It was still around 80v, so it must have been much higher undamped. Not being a digital storage scope it was hard to see, and undamped impossible.

It seems that the inductive flyback from a stalled wiper motor is enough to somehow escape the relay, find it's way out through the driver transistors back on to the CPU board. That means pretty high voltages... maybe over 1kV. I'm just glad I didn't fry the CPU or any of it's pins.

All together now:

The software and UI got some bugs fixed, and other upgrades. Hopefully a will do a brew tomorrow night.