You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Zizzle's Brewbot

- Thread starter Zizzle

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Jye

Hop Junky

- Joined

- 9/5/05

- Messages

- 3,190

- Reaction score

- 8

bonj

Premier Ipswich Mash Proponent (PIMP)

- Joined

- 1/12/06

- Messages

- 2,816

- Reaction score

- 13

Well anytime your down this way give me a yell. Otherwise will do a brew day in the next couple of months.

Will do. A brew day sounds like a plan too.

Zizzle

Well-Known Member

- Joined

- 22/4/06

- Messages

- 1,001

- Reaction score

- 5

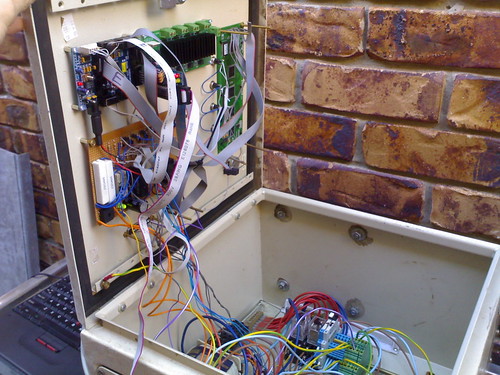

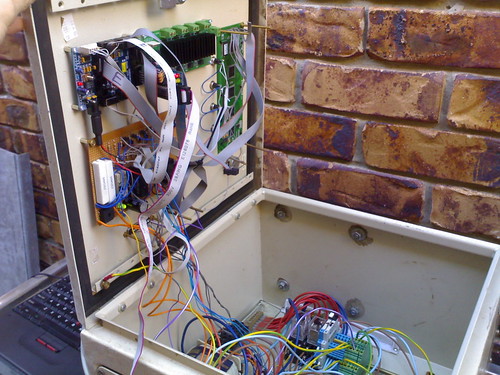

Brewbot now has a brother. One of the local forum members has been busy working away with a little help.

Although heavily influenced by the orginal, brewbot2 has it's own customisations. Similarly built from largely scrounged and improvised parts.

Aimed at a more permanent installation, it had it's inaugural run with success last night.

Gravity fed, 3 tier setup, attached to a wall.

The brains, hardware very similar to the original.

Some niceties are afforded by the permanent setup, such as being connected directly to a dedicated 25amp circuit.

March pump and windscreen wiper actuated ball valve.

HLT in the sky and it's wiper actuated ball valve.

Brewbot2 may actually beat the orginal to having a HERMs integrated.

Please form an orderly queue those wanting to place an order for Brewbot3

Although heavily influenced by the orginal, brewbot2 has it's own customisations. Similarly built from largely scrounged and improvised parts.

Aimed at a more permanent installation, it had it's inaugural run with success last night.

Gravity fed, 3 tier setup, attached to a wall.

The brains, hardware very similar to the original.

Some niceties are afforded by the permanent setup, such as being connected directly to a dedicated 25amp circuit.

March pump and windscreen wiper actuated ball valve.

HLT in the sky and it's wiper actuated ball valve.

Brewbot2 may actually beat the orginal to having a HERMs integrated.

Please form an orderly queue those wanting to place an order for Brewbot3

Zizzle

Well-Known Member

- Joined

- 22/4/06

- Messages

- 1,001

- Reaction score

- 5

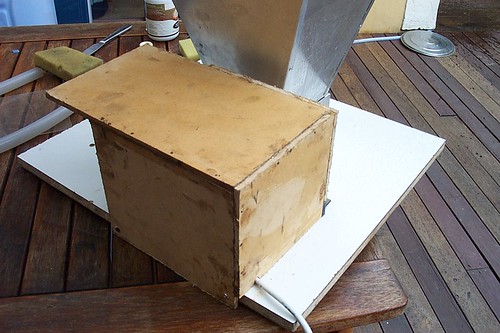

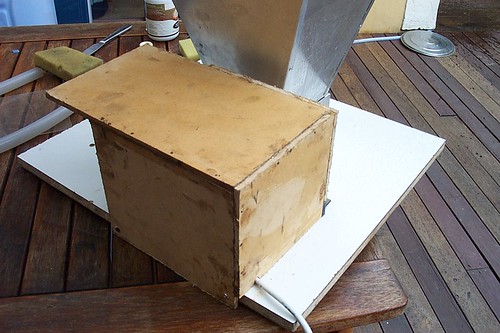

Got busy motorising my Barley Crusher using a garage door opener fished out of the bin (thanks Brad!). A nice little 200w 240v DC motor with worm drive and other reduction gears.

Then a quick'n'ugly MDF box over the lot to keep little fingers out of the high voltage areas & gears.

One less thing to have to stuff around with on brew day.

Then a quick'n'ugly MDF box over the lot to keep little fingers out of the high voltage areas & gears.

One less thing to have to stuff around with on brew day.

Zizzle

Well-Known Member

- Joined

- 22/4/06

- Messages

- 1,001

- Reaction score

- 5

Not content to have a brewbot that actually worked I had to go and want it to be more compact. I also wanted to get rid off all brass & copper in contact with the wort. So part of the reorg is to minimize the number of fittings to replace.

Cut the frame in half and upended it...

The HLT now gravity feeds the MLT so the old actuated brass gates valves are gone, and a new ball valve mechanism...

Now just waiting for some more stainless steel bits to show up... brass be gone...

Cut the frame in half and upended it...

The HLT now gravity feeds the MLT so the old actuated brass gates valves are gone, and a new ball valve mechanism...

Now just waiting for some more stainless steel bits to show up... brass be gone...

sqyre

Bee & Thistle Brewery

- Joined

- 15/2/06

- Messages

- 1,544

- Reaction score

- 15

I couldnt help think of you today Z-man... and no i wasnt interfering with myself in the shower... <_<

My work chucked out thier old massive photocopier.. so i grabed it... why? i dont know...

But when i got home i plugged it in and started copying stuff (including my bum) untill i got bored...

Then as most bored red blooded Aussies with an insatiable curiousity do... i grabbed my philips head screwdriver and went to town in demolision mode...

I was rather hoping i would find a nice big motor with a half decent reduction drive on it to use for my Grain Mill but no luck so far..

However... i did stumble across a bunch of small motors with frigin major reduction drives...

24v -1.85 RPM

They are all plastic but I reckon they might be alright for turn taps on and off..

Sqyre...

My work chucked out thier old massive photocopier.. so i grabed it... why? i dont know...

But when i got home i plugged it in and started copying stuff (including my bum) untill i got bored...

Then as most bored red blooded Aussies with an insatiable curiousity do... i grabbed my philips head screwdriver and went to town in demolision mode...

I was rather hoping i would find a nice big motor with a half decent reduction drive on it to use for my Grain Mill but no luck so far..

However... i did stumble across a bunch of small motors with frigin major reduction drives...

24v -1.85 RPM

They are all plastic but I reckon they might be alright for turn taps on and off..

Sqyre...

sqyre

Bee & Thistle Brewery

- Joined

- 15/2/06

- Messages

- 1,544

- Reaction score

- 15

Not sure if i want "The Stairway" being assimilated by the Borg just yet...

i have been in the shed stripping the photocopier down some more looking for goodies and i found a decent sized 20:1 reduction gearbox..

So i've been working on modifying that to hopefully power my grain mill...

its got plastic gears but hopefully the strain on it wont be too harsh...

also if you want any bits and pieces, like small gears, cogs,pullies etc. there are heaps in this copier you can have..

there also a heap of small electric clutches if you have a use for them, as well as a heap of other thing-a-me-jigs...

Sqyre...

i have been in the shed stripping the photocopier down some more looking for goodies and i found a decent sized 20:1 reduction gearbox..

So i've been working on modifying that to hopefully power my grain mill...

its got plastic gears but hopefully the strain on it wont be too harsh...

also if you want any bits and pieces, like small gears, cogs,pullies etc. there are heaps in this copier you can have..

there also a heap of small electric clutches if you have a use for them, as well as a heap of other thing-a-me-jigs...

Sqyre...

alexbrand

Well-Known Member

- Joined

- 23/5/07

- Messages

- 271

- Reaction score

- 21

New shiny toys: [...]

Zizzle,

don't you have any problems with caramelizing the wort's sugar on the heating coils at boiling time?

Alex

afromaiko

Incredibly Strong Ales

- Joined

- 15/10/06

- Messages

- 555

- Reaction score

- 1

New shiny toys:

So no more hot acidic wort sitting in copper & brass for hours at a time.

Where did get the stainless pick up tube and fitting from? I'm going to add a pick up tube, but everything else is stainless so I wanted to steer clear off copper and brass too.

Zizzle

Well-Known Member

- Joined

- 22/4/06

- Messages

- 1,001

- Reaction score

- 5

don't you have any problems with caramelizing the wort's sugar on the heating coils at boiling time?

I've had the problem occur once. It was my first go at a wheat beer. So maybe something to do with the wheat, I don't know.

Since then I have modified the hardware so that all the elements are driven via triacs so that I can vary the duty cycle in software. For the last 6 or so brews (including a successful wheat beer) I have been driving the elements at 85% duty cycle. 2 x 2200w x 0.85 = 3740w. There is usually some white gunk on the elements after a boil, but it wipes right off and doesn't taste caramelised at all.

New stainless bling is from beerbelly.

Similar threads

- Replies

- 111

- Views

- 19K