First brew of the rig...

Configured up my equipment within beersmith and knocked up a American Brown Ale Recipe

tyle : American Brown Ale

batch size : 23lt

Ingredients:

------------

Amount Item Type % or IBU

4.80 kg Vienna Malt (3.5 SRM) Grain 92.31 %

0.25 kg Chocolate Malt (350.0 SRM) Grain 4.81 %

0.15 kg Carapils (Weyermann) (2.0 SRM) Grain 2.88 %

30.00 gm Amarillo [7.80 %] (60 min) Hops 25.3 IBU

20.00 gm Amarillo [7.80 %] (25 min) Hops 11.7 IBU

15.00 gm Amarillo [7.80 %] (5 min) Hops 2.5 IBU

1 Pkgs SafAle American Ale (DCL Yeast

#US-05(56))Yeast-Ale

60min MASH 67.8 with a mash out

60min boil

10~days fermenter at 20c (maybe 18c)

The Crush.

In all my excitement I forgot to build a mount for my grain mill so i had to hold it over a bucket and hand mill.. This proved to be quiet hard but got there in the end.

The grain mill worked great and had a nice crush, will be a lot better with a mount and my mill motor connected up again.

Pre-heat

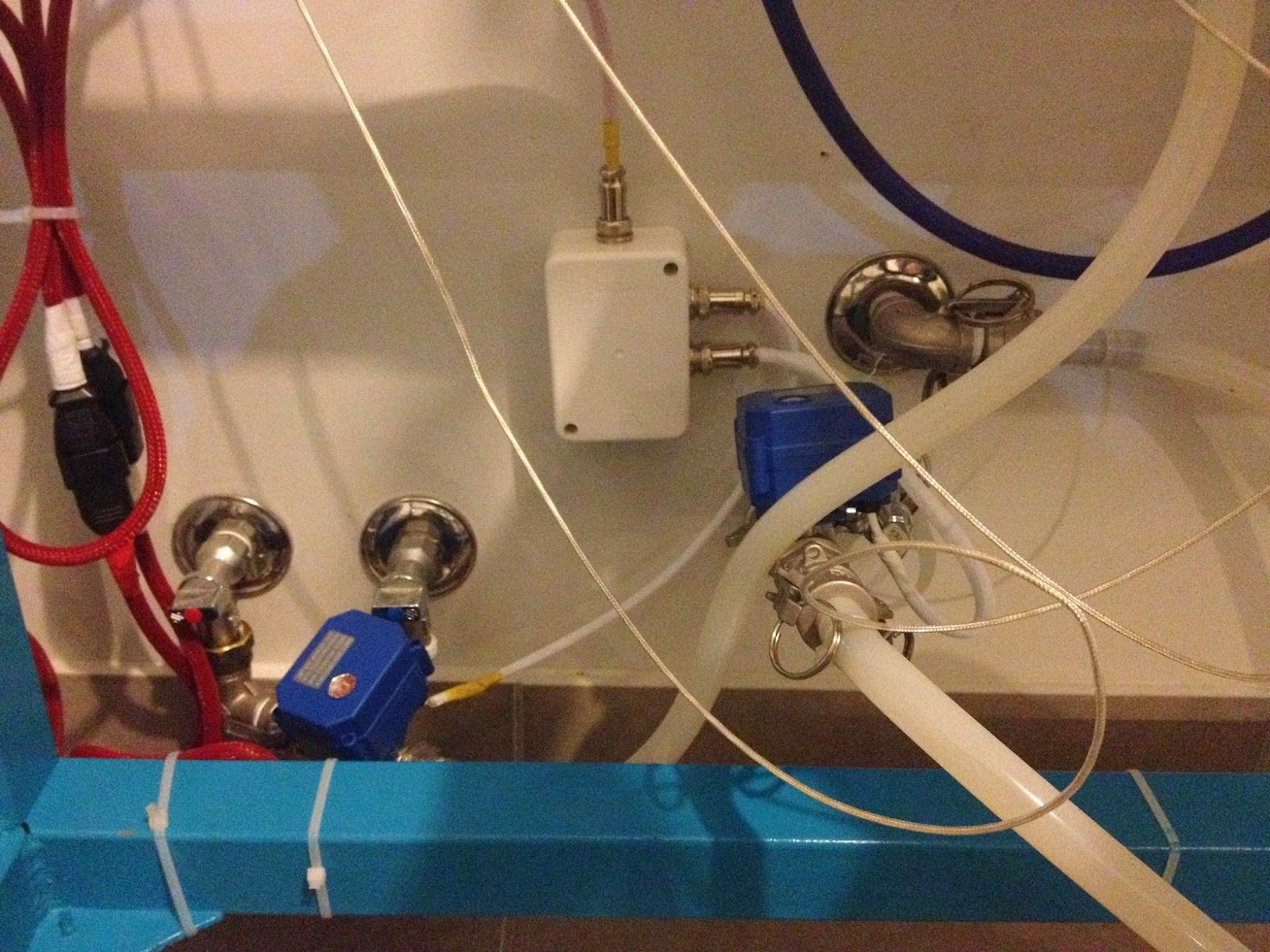

Put in enough liquid to cover the HERMS coil and got up to temperature, Once reached I dumped enough out to the MLT and refilled my HLT back over the HERMS started to push the MLT through the HLT to get up to temp.

Once up to temp i dumped in the grain and stirred,this went well and I started my mash.

Mashing

Pumps worked well, 1 pushing the hlt water around so it keeps the temperature constant and the other pushing the wort through the HERMS coil from the MLT. At this point I notice the temp probes not showing the same thing, I then remembered i didn't calibrate ANY of my probes and pretty much thought this beer isn't going to work to well, didn't mind since it was more about working the rig out.

Mashout

Did a mashout and allowed 15mins for the mash to get to mashout temp (75c) the HERMS functioned beautiful once temp reached I did a 10min mash-out. the auber instruments timer worked great.

Fly-Sparging

Since I've never had a system setup for fly-sparing I've never tried it before, After doing my first one I thought "Why does't everyone do this!?" pumps on, water matched speed into the kettle and just turn it off once you get to your pre-boil level.. great!

Boiling

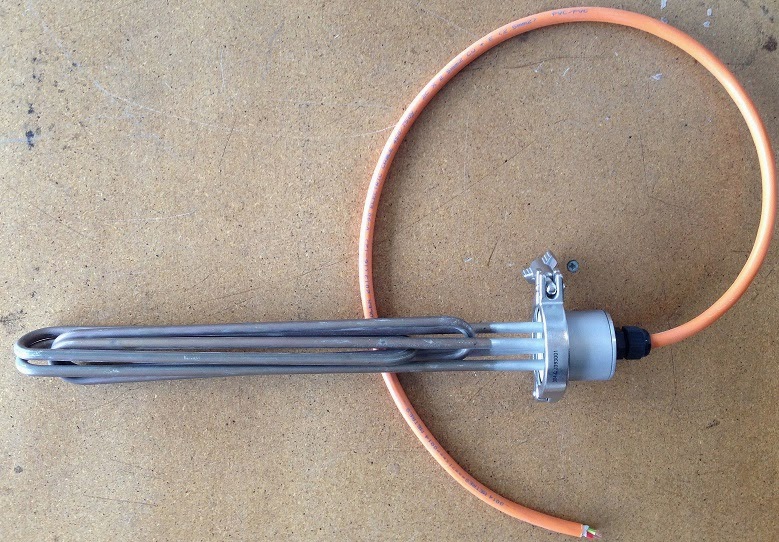

While I was sparging and after the wort is over the element I turned on the BK element (4800watt) This got the wort up to boiling within about 15minutes which was a lot better than my last pot. Since it was only 27lt in the pot the 4800 element had a very aggressive boil so I had to set my PID to 97% since helped. The whirlpool return port was fantastic, previous pot I had to dump it over the lid for the return, with the return port I could put the lid on.

Chilling

I've hard plumbed my chiller into my tank and all i had to do is turn the switch on the control panel which was awesome! no moving hoses, no connecting anything was bliss.. The chiller (as you can see above) worked great! since my tank water isn't really cold it slowed down a-lot down to the top 20's but I think if I had a pre-chiller or from mains it could be quicker but it was quick enough.

Control Panel

The "the electric brewery' clone control panel worked great! everything was in a logical place, I tried to keep the switch in the same type of location as my rig.. i.e. first switch down the bottom in "hot water in" because the port in the wall is on the far left of the brewery.. then Pump 1, Pump 2 and then Chiller.. So when I look at the rig I know where it should be on the control panel.. same goes with the elements.. Works in my mind anyway

Tri-Clover Fittings

Tri-Clover Fittings

The fittings were a little fiddly on the first few swaps but I got the hang of it, The time tri-clovers really shine is in the clean up.. Just take the fittings off and you can see everything.. none of this wondering if the threads have stuff in it.. love it for that!

Conclusion

This is a great unit and I'm very happy with it... it performed very well it was just the operator who stuffed up some water/grain ratio due to not correctly judging the MLT dead space. I will also need to calibrate ALL the temperature probes and dial which will take the second guessing away and let me relax.

All my other breweries were weld-less fittings and leaked a little bit, Having full welded fittings was a dream, no check to see if something is leaking not turning the ball valves to hard just encase I unscrewed the bulk head enough it gets a leak. It certainly was another level in my brewing, Now I just have to produce some sweet beers off it.

I think I'll keep this a quick write up since I'm yet to dial my rig in, but the first look is very impressive.

Cheers

Gavin.