Zizzle

Well-Known Member

- Joined

- 22/4/06

- Messages

- 1,001

- Reaction score

- 5

Haven't had much time to spend on the brewbot recently, but have been anyway

It's nearly done, except for the hop dropper.

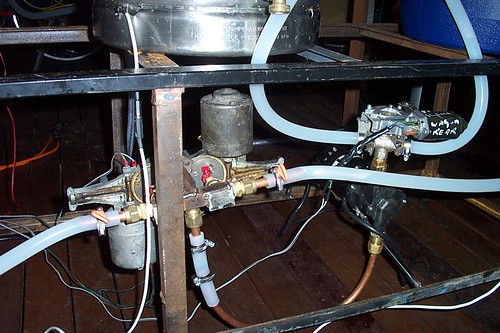

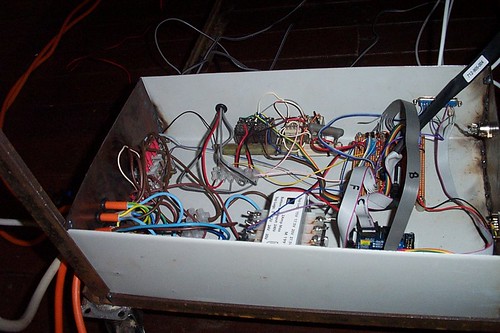

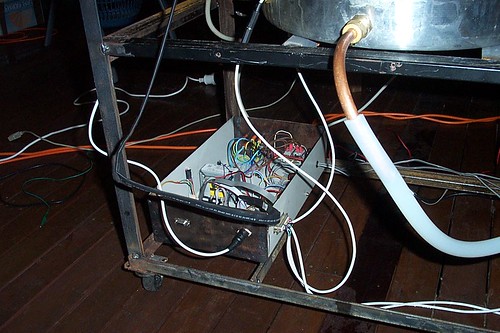

Brew bot can automatically fill it's HLT from the mains water, heat that to mash temp, pump 15lts from the HLT to the mash tun, mash for 60mins, heat water for mash out, pump 7ltrs of that to the mash tun, refill HLT and heat 23ltrs of sparge water.

The code for all steps is written, the above is all I've had time to test so far. The has been a few bugs and glitches, but overall I'm happy with how it is working.

Pics tomorrow when I figure out why my camera has stop talking to my laptop.

It's nearly done, except for the hop dropper.

Brew bot can automatically fill it's HLT from the mains water, heat that to mash temp, pump 15lts from the HLT to the mash tun, mash for 60mins, heat water for mash out, pump 7ltrs of that to the mash tun, refill HLT and heat 23ltrs of sparge water.

The code for all steps is written, the above is all I've had time to test so far. The has been a few bugs and glitches, but overall I'm happy with how it is working.

Pics tomorrow when I figure out why my camera has stop talking to my laptop.