hook it up and throw some grains in Wolfy.. the suspense is killing me :lol:

Getting there! Should be able to run a test-brew in the next few days, but I've only just started to re-culture some yeast, so have to wait for that before I can do anything real.

#14: Fit-out, Leak Test & Burn-in

1000-word blog rant

After assembling all the fittings and putting things together, I've come to the following realizations:

Tapered fittings (NPT) work best for pipe-to-pipe type connections, such as attaching valves to fittings or camlocks. The tapered thread, combined with some thread-tape, locks the fitting in place and prevents leaks without additional seals or gaskets.

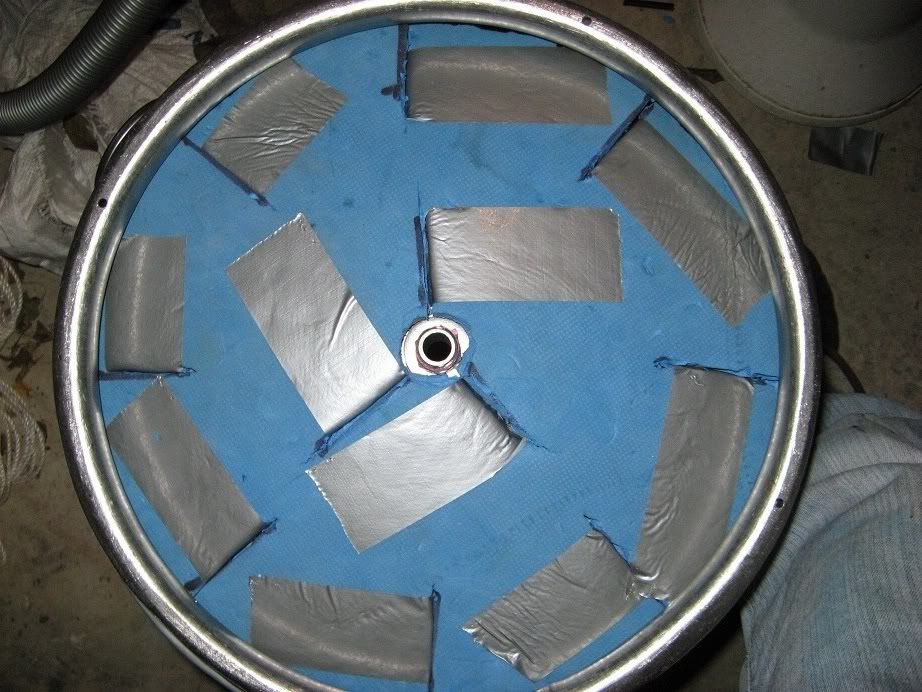

However, NTP fittings are much less useful for bulkhead-type connections through keg walls. Due to the tapered thread, the nut or fitting must tighten exactly as it compresses the gasket/or washer against the wall. However, the fitting can easily lock-tight too quickly (and not seal to the side of the vessel) or not tighten quickly enough (potentially allowing for leaks along the thread). So additional spacers- silicon (not visible in the picture) and steel washers are required:

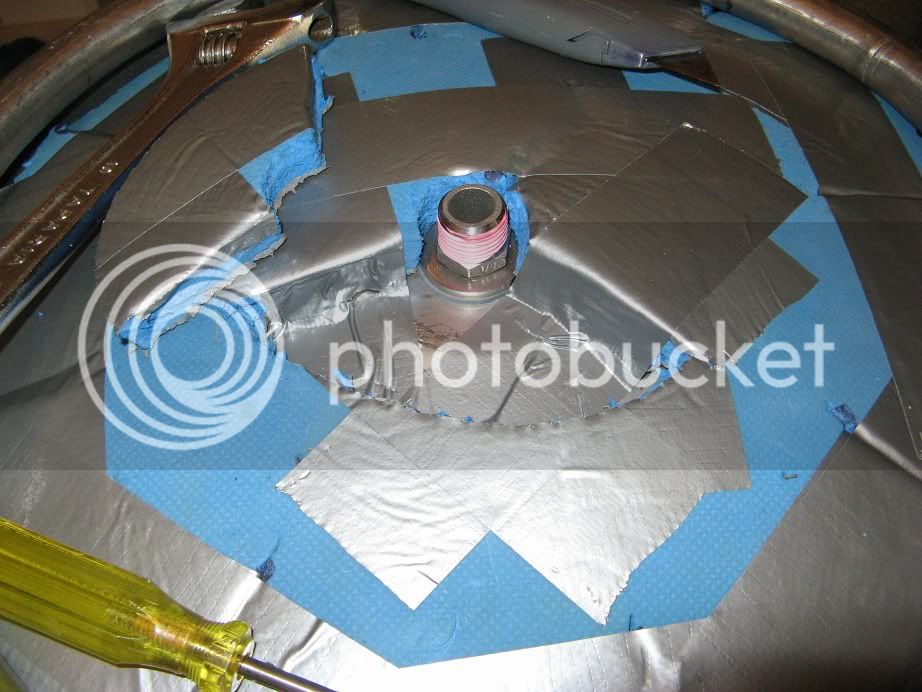

On the other hand parallel threaded fittings (BSP(P)) work much better as bulk-head connections. Thread-tape prevents leaks along the thread and the fittings tighten securely against the side of the vessel, meaning that a water-tight seal can be made with just a locknut and a silicon o-ring:

With this in mind - and knowing that at 1/2 inch size both BSP and NTP threads mate without problem - bulkhead type connections through the wall of a vessel would be made best with a parallel BSP thread, while fitting-to-fitting connections like the ball valves, are best using tapered NTP thread.

The Chinese Ebay supplied lock-nuts have an o-ring groove cut in them so the easiest and cheapest method for sealing through-keg bulkheads is simply to use the nut and a silicon o-ring (thermowell picture above). However as the fitting is tightened the o-rings can deform or break easily making them less than useful, and essentially useless in any situation that does not have a channeled-nut for them to sit inside. As a consequence many of the fittings (especially if they were through the keg with NTP) required both a silicon washer and stainless shim-washer. Most bulkhead fittings were sealed on the inside in order to to stop the water/wort from getting into the threaded connection and between the fitting and the keg-walls.

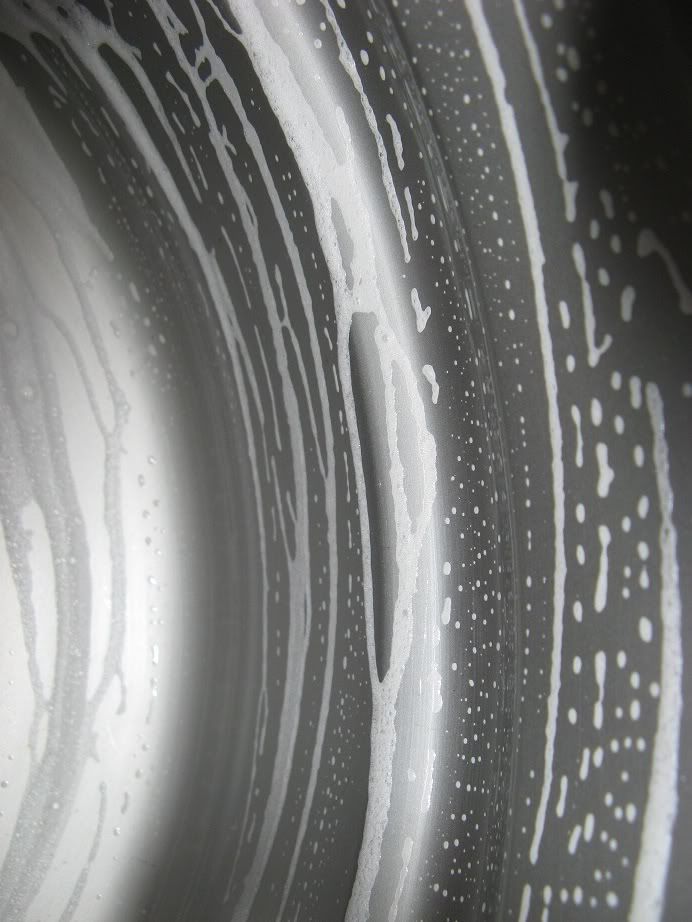

Sight-glass works well once the keg is full of water:

Filling the kegs with water, indicated a few fittings needed to be tightened or re-assembled, but by the time I was finished all of the seals were water-tight first time. Once that was done it was time for a burn-in test, or more correctly a boil-in, by connecting the element directly to the power-socket and running it for about an hour.

Probably something that could be skipped, but in this case the silicon seal 'slipped' - likely due to the fitting being over-tightened - after about 45mins and ended up spilling boiling water all over the floor:

Since I was a little lax in cleaning up after cutting, drilling, filing and grinding, it's possible that bits of metal were left inside the keg which caused a little bit of surface rust after the first test:

The Stainless Cleaner, a scrubby and a bit of rubbing removed them fairly quickly.

And it looked like new again, next time I'll be more pedantic about cleaning things after playing with power or hand tools.

After the 1 hour test-boil the cord and element-connection were quite warm, so it's easy to understand how a bit of pressure or pulling could causes problems. Hopfully some tape, spiral-wrap and a cable-tie will help keep thing safe and secure: