Update #18: Wort!

Blog rant

After a bit of time, effort and money, it was nice to have it finally do what it should ... make some wort:

I thought it was surprisingly clear into the fermentor, I no-chilled 24L into 2 x 10L jerrys and tipped the last 4L.

I've had a 4.8kg bag of Wey Pils that G&G crushed for me 3+ years ago, it's been sitting around since then and even sustained a family of mice for a while. So I figured it would be a good test-run for the new system, with the intention of no-chilling and if they don't get infected, use the wort for lager-starters that (in theory) I might be making soon.

Filling the HLT, food-grade water-hose ($20 on Ebay from a mob in Dandenong) directly from the shower-outlet .

I plan to fill the HLT the night before brew-day so that any chlorine will have time to dissipate.

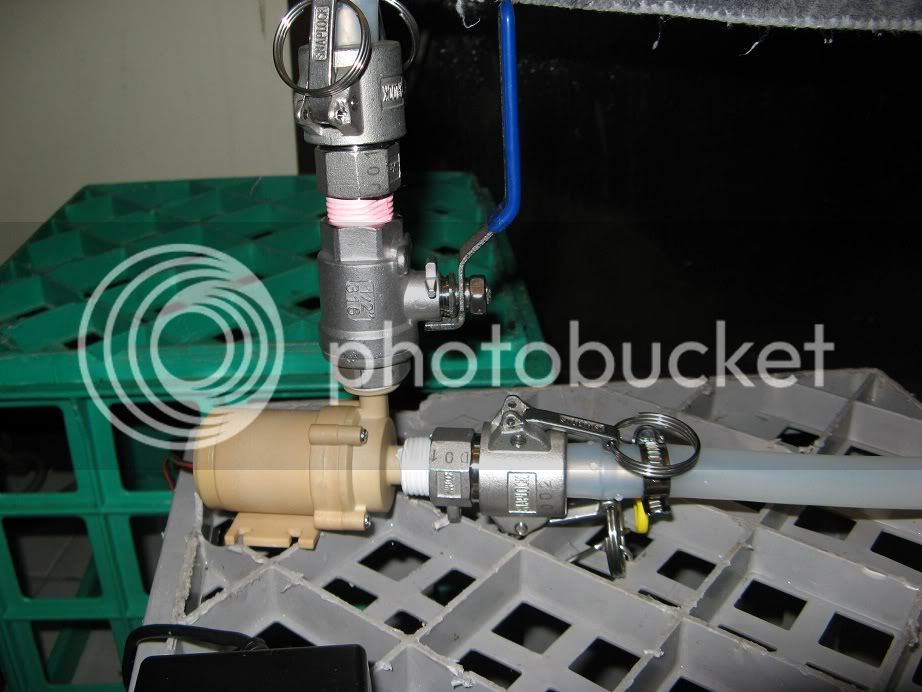

Filling the mash-tun from the bottom, via the pump, HERMS and hoses:

HLT was set to 60C but by the time it was all mixed the mash-thermometer read 45C, so I'll need to test/calibrate what temperatures are required.

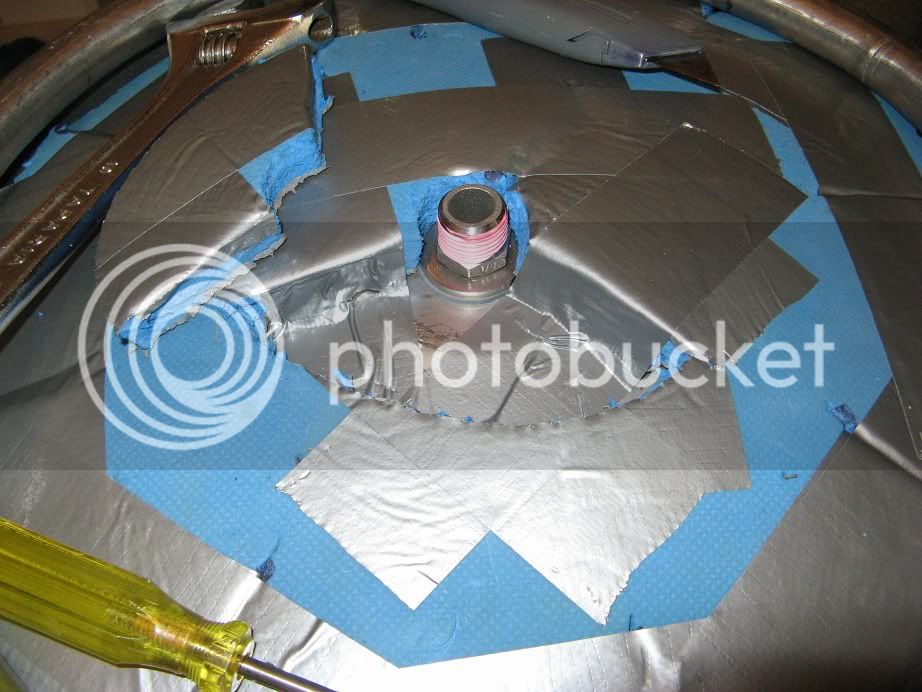

HERMS is not quite finished yet, it works fine, but needs to have the lid fitted and the fittings attached to that, but I wanted to check that it worked as expected while I could see what was going on.

No dough-balls undeletting at what turned out to be about 45C:

Mash-filter worked well, no problems circulating even right at the start:

One of the main problems I did have was uncalibrated thermometers and difficulty understanding the PID instructions (or the bloody thing not working quite as expected).

Not sure if the auto-tune stuff worked or not, and for a while it seemed to think that 67C was a good temperature to run when I had it set to 65C.

The mash-tun dial-thermometer consistently read 2C less than the PID, which means either one or both need calibrating and/or there were losses via the hose/mash tun.

The HLT probe also appeared to be 2-3C out, so I will need to buy a decent scientific glass thermometer and calibrate them all.

As expected, after an hour of recirculation the wort was clear:

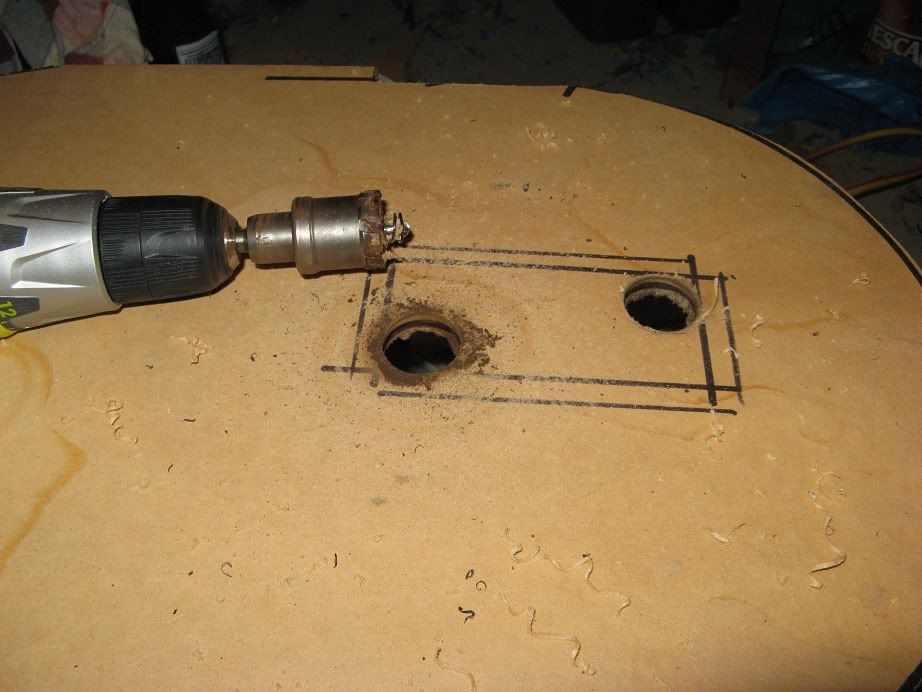

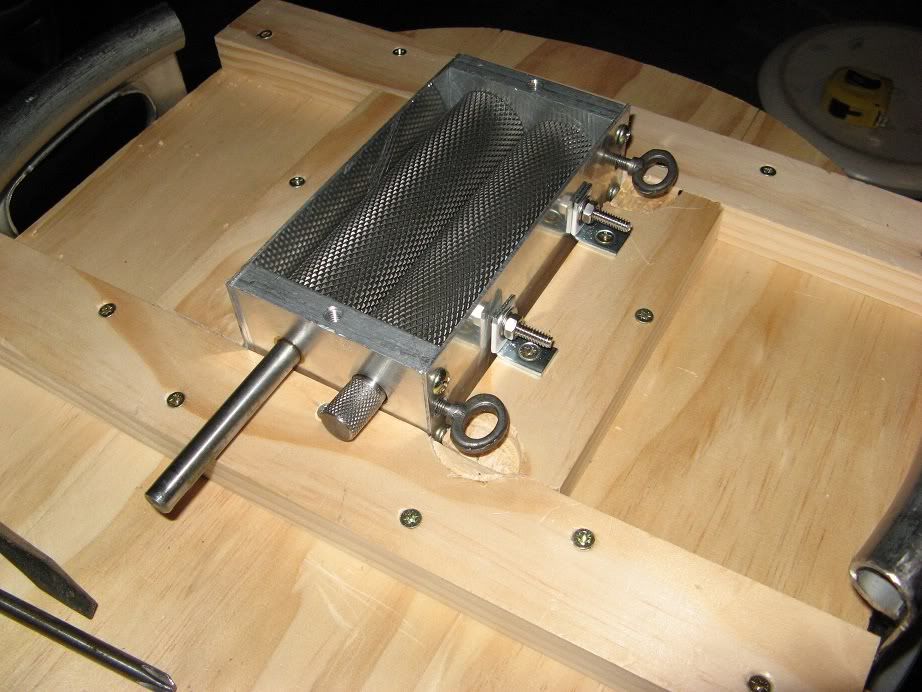

One of the things still on the 'to do' list is a better wort-return-mechanism, but I wanted to run a test first to check volumes/sizes/headspace and the like.