Yob

Hop to it

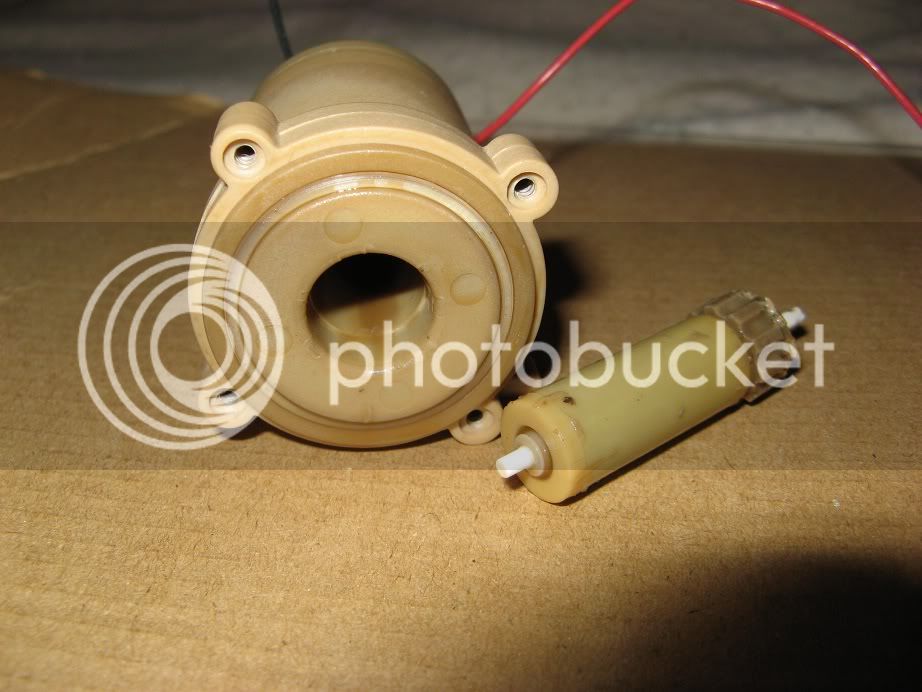

is that nipple at the top for the future sparge arm?

h34r:

h34r:

Would you want a more active boil than in the single-element-video?excellent stuff, maybe make up a power adjuster (light dimmer) as 1 element is probably not good enough for a rolling boil (it could be close) ??

The kettle, which actually still has the silicon hose from the nipple to the bottom of the kettle (avoiding the elements) in the video?is that nipple at the top for the future sparge arm?

Yep, as per: http://www.aussiehomebrewer.com/forum/inde...st&p=917684Where did you source the perf stainless inserts? Buy a sheet and cut it?

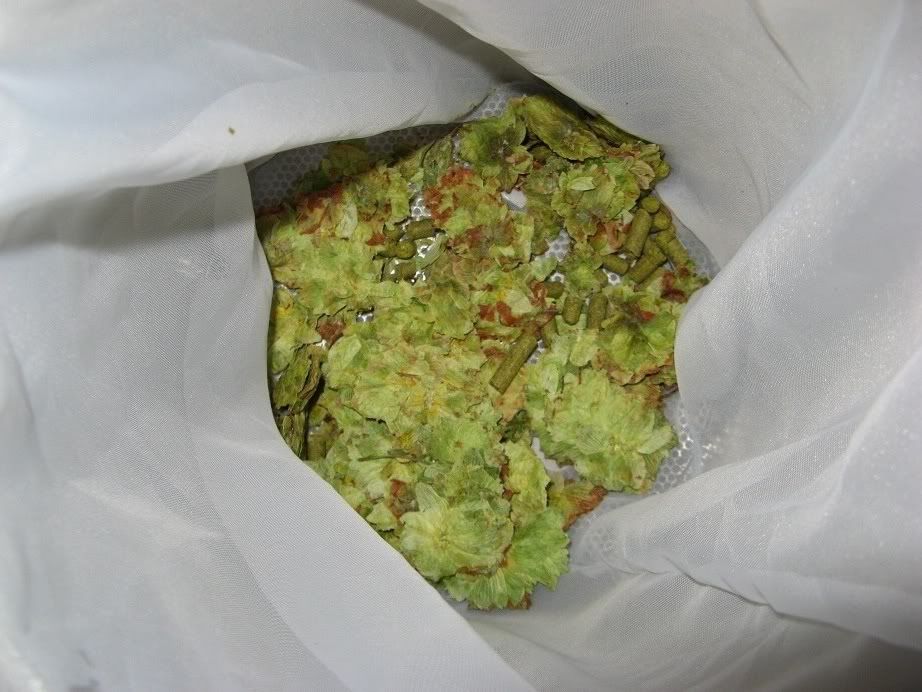

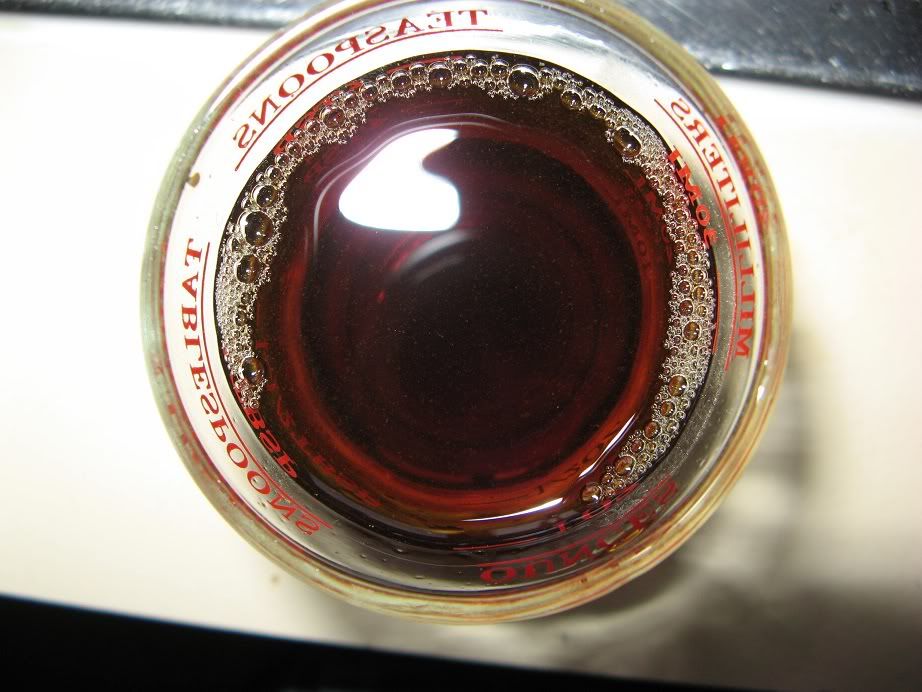

Wort looks fantastic in the last shot, nice work.

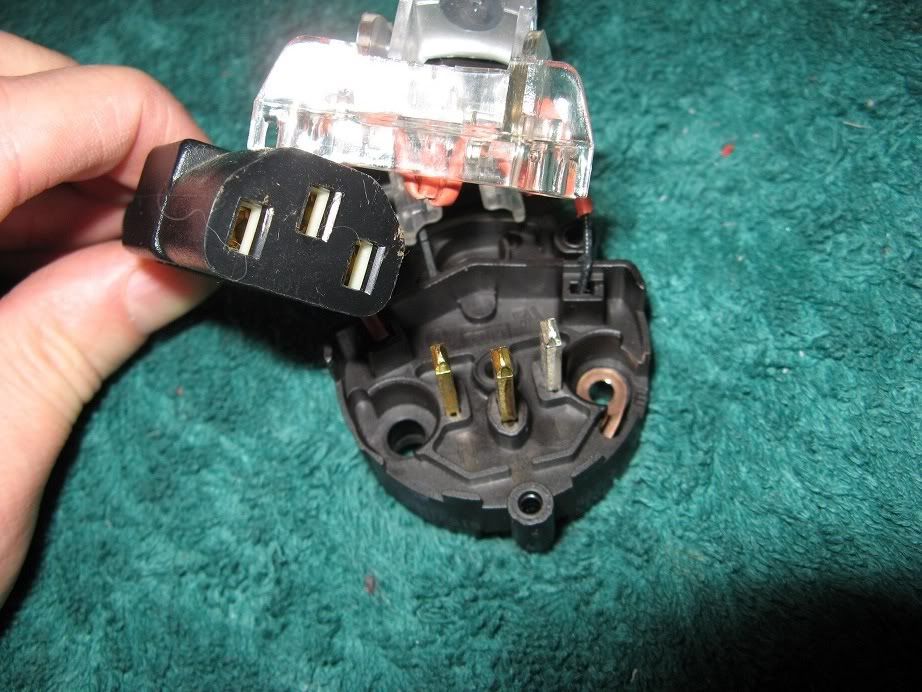

It's a consideration, especially with a proper brew-stand, however even the generic 'Double ferrule Tube Fitting' required to attach the stainless tube are quite expensive (I think).Nice work as always wolfy! With all that spare ss tube, have you considered fully hard-plumbing your rig?

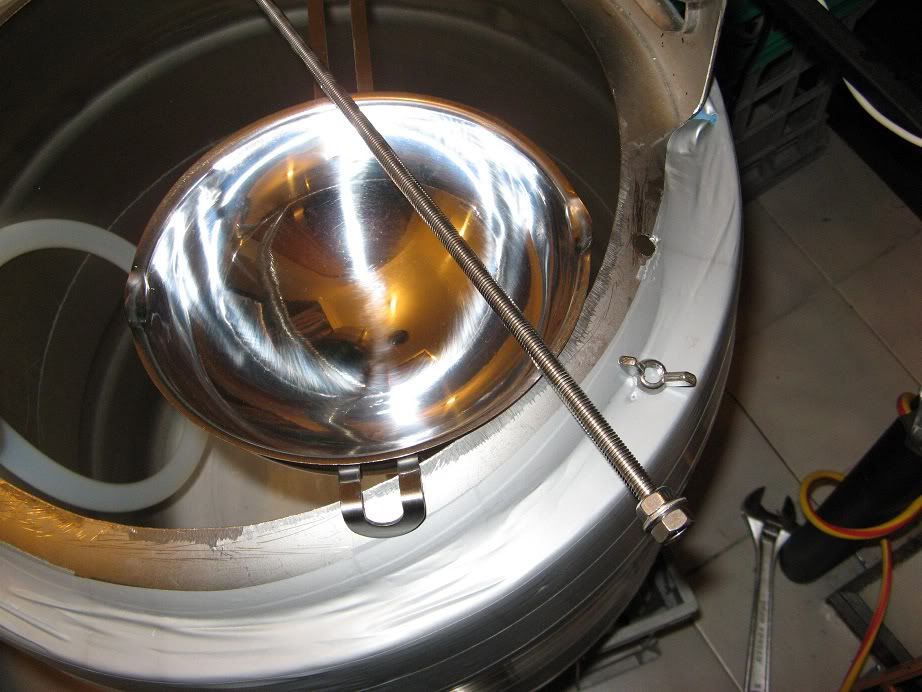

For small/single batches, the 1L volume is likely a little large and the return-dish is a little too deep, so I'll find a cheap shallow stainless bowl (discount store), drill a hole in the lip of the bowl and use that (instead of the double-boiler-insert) when mashing small grain-bills.

Yep, something like that would work well, I'll have to check for those in the cheapie-shops too.I've got a set of stainless steel measuring cups, like these:

I reckon one of these could be easily jury-rigged into replacing your bowl for the return dish, losing you no more than 1/4 to 1 cup of wort.