vicelore

Well-Known Member

- Joined

- 19/11/07

- Messages

- 408

- Reaction score

- 0

Hey guys

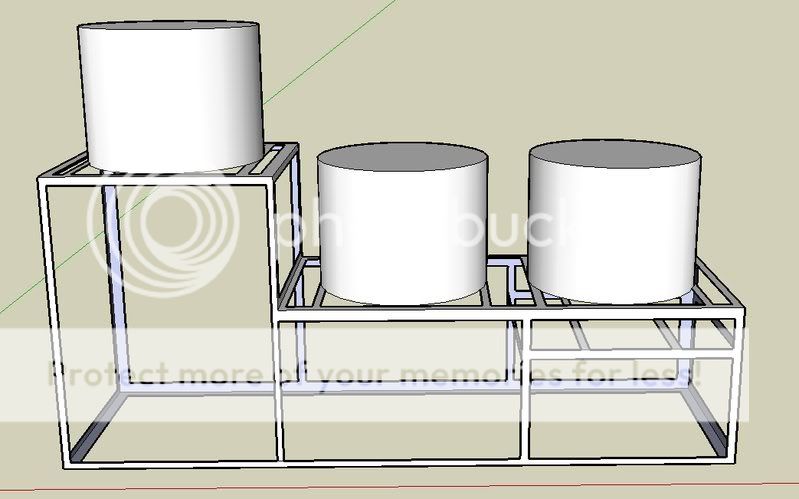

Well i started my brewery last night.

Using some heavy duty Galv steel L for the build as i cannot weld. I herd this woudnt rust and would hold up to the heat well.

Im going to be adding a extension to hold my HLt then run a March pump from the MT to the Kettle. As well as some supports in the middle.

Here is a pic of what we got done last night.

It wasnt a kit of any type so a fair bit of cutting was done last night with a VERY blunt hack saw.. and yes i would kill for a drop saw..

Cheers Vice

Well i started my brewery last night.

Using some heavy duty Galv steel L for the build as i cannot weld. I herd this woudnt rust and would hold up to the heat well.

Im going to be adding a extension to hold my HLt then run a March pump from the MT to the Kettle. As well as some supports in the middle.

Here is a pic of what we got done last night.

It wasnt a kit of any type so a fair bit of cutting was done last night with a VERY blunt hack saw.. and yes i would kill for a drop saw..

Cheers Vice