They are used for approximating parameters with changing speeds and for practical purposes they hold quite well. I use them a lot commissioning pumps that are fitted with a VSD and run anywhere between 15 and 80Hz yet we are supplied with 50 and 60hz curves only. While not an exact science they certainly get you in the ballpark when designing a system.klangers said:Not quite.

Centrifugal pumps are not positive displacement pumps, so flow is not proportional to anything simple. If it were a reciprocating pump, then yes, it would be proportional to speed.

Flow through centrifugal pumps is related to the difference in delivery pressure and back pressure in your piping system. The back pressure in your piping system is proportional to the flow and hydraulic parameters of the piping system. As you can see, this requires iteration to solve as it's a simultaneous equation.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pump for CIP spray ball

- Thread starter Damranger

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Or you could go all out and put it on a variable speed drive. It has the added benefit of being able to vary the speed as well as buy a more readily available 3 phase pump(if you go the hygienic option). The VSD will allow you to run a 3 phase motor on a single phase power supply as long as its a small enough motor to not exceed the current available. I have all the bits to do exactly this to CIP a small fermenter but haven't got around to it in the past 12 months. If I get around to it I'll post a pic here of the setup.malt junkie said:How ridiculous is a simple food grade CIP pump going to get? I mean you can get a little 60hz petrol genny pretty cheap. Is that going to be the simplest, cheapest, most effective solution. (with the chugger landed you'd still be under a grand.) And you could use the gen set to run your standard March/Chugger when brewing and see a step up in performance there too.

Ed: if you have solar some inverters will do 60hz too.

malt junkie

Well-Known Member

So would a simple VFD do the job of uping the fequency for the chugger/march?husky said:Or you could go all out and put it on a variable speed drive. It has the added benefit of being able to vary the speed as well as buy a more readily available 3 phase pump(if you go the hygienic option). The VSD will allow you to run a 3 phase motor on a single phase power supply as long as its a small enough motor to not exceed the current available. I have all the bits to do exactly this to CIP a small fermenter but haven't got around to it in the past 12 months. If I get around to it I'll post a pic here of the setup.

Lyrebird_Cycles

Well-Known Member

- Joined

- 10/7/16

- Messages

- 1,439

- Reaction score

- 777

The specs on this pump say it will do the job*, $120 plus shipping..

https://www.aliexpress.com/item/0-37KW-Stainless-Steel-Water-Pressure-Booster-Pump-Self-Priming-Pump-Durable-for-Corrosive-Liquid/32675984602.html

* I'd take the specs with a grain of salt: the claim for the pump two sizes up is that it will operate with NPSH of 12m, that's physically impossible at sea level.

https://www.aliexpress.com/item/0-37KW-Stainless-Steel-Water-Pressure-Booster-Pump-Self-Priming-Pump-Durable-for-Corrosive-Liquid/32675984602.html

* I'd take the specs with a grain of salt: the claim for the pump two sizes up is that it will operate with NPSH of 12m, that's physically impossible at sea level.

Lyrebird_Cycles

Well-Known Member

- Joined

- 10/7/16

- Messages

- 1,439

- Reaction score

- 777

Yes. I have a single phase to 3 phase VFD on the pump for my RO system, it happily runs up to 70 Hz.malt junkie said:So would a simple VFD do the job of uping the fequency for the chugger/march?

You need to be careful at speeds higher than this you can cook the motor if you are not.

Whoa, you have an RO system? Off topic, but is it a tiny packaged plant? Did you assemble it?

Edit: What am I thinking.... it is LC here.... I wouldn't be surprised if he had his own space program (non-kerbal)

Edit: What am I thinking.... it is LC here.... I wouldn't be surprised if he had his own space program (non-kerbal)

As long as the pump motor is 3 phase then yes.malt junkie said:So would a simple VFD do the job of uping the fequency for the chugger/march?

Lyrebird_Cycles

Well-Known Member

- Joined

- 10/7/16

- Messages

- 1,439

- Reaction score

- 777

Yes, I built the prototype for Memstar's bench top RO system. I still have it (well actually it's at a mate's winery in Griffith). It was designed to do wine so it runs at very high pressure with a very tight membrane ( ~150 Dalton MWCO) but I have a selection of other membrane cartridges up to NF scale: we did some experimental work on double membrane desalting of whey isolates.zorsoc_cosdog said:Whoa, you have an RO system? Off topic, but is it a tiny packaged plant? Did you assemble it?

Edit: What am I thinking.... it is LC here.... I wouldn't be surprised if he had his own space program (non-kerbal)

My elder brother is the one with the life long passion for rocketry.

malt junkie

Well-Known Member

malt junkie said:So would a simple VFD do the job of uping the fequency for the chugger/march?

husky said:As long as the pump motor is 3 phase then yes.

I'm Obviously not a sparky, but I don't get it. If I increase the frequencey across the 3 output phases to 60hz but only choose to use one of those phases, or use each phase separately on separate circuits should I not result in 60HZ at each phase?

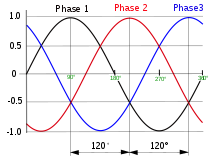

Hope this helps MJ,malt junkie said:I'm Obviously not a sparky, but I don't get it. If I increase the frequencey across the 3 output phases to 60hz but only choose to use one of those phases, or use each phase separately on separate circuits should I not result in 60HZ at each phase?

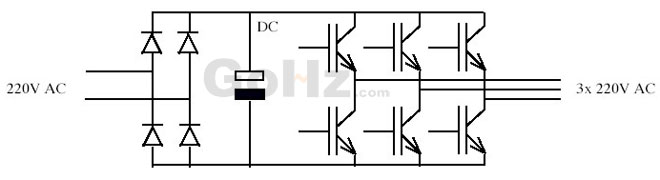

Single phase in, three phase out.

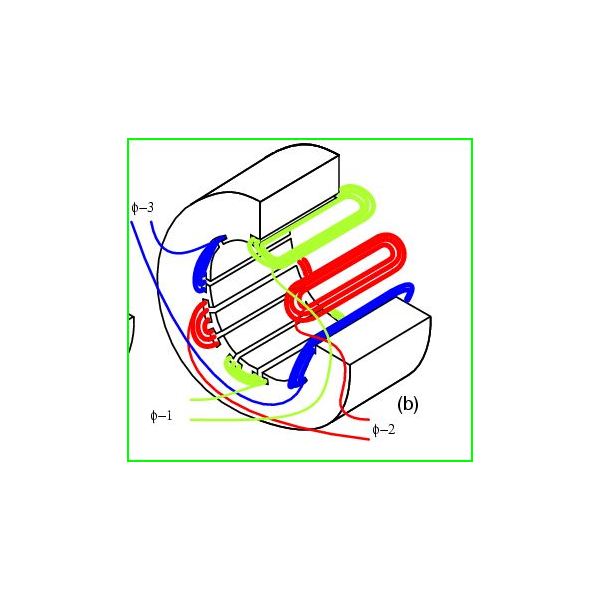

Asynchronous (induction) motors made for three phase are balanced with all three phases delivered to the motor.

The output of this type of device would be like this

And yep, all three of them will have equal frequency. Possibly 60Hz as you say.

The three phase motor windings can be shown like this

Well, that's something.

Single phase in, Variable Frequency device creating three phases like the waveform above, then those phases delivered to the motor.

All on, and hopefully all balanced.

If you use a device that creates three phases from a single phase, you could rightly separate the phases out, but it probably needs a ZN earthing transformer, some funky protection and some time.

Those three phases are a family and need to stay together to drive their load mate.

I'd have to see if there are VFDs that output to star connection. That would make separating the phases apart easy. Can't say I've ever designed a system that way though.

Edit: Fire back with questions mate, I'll try and help further.

Lyrebird_Cycles

Well-Known Member

- Joined

- 10/7/16

- Messages

- 1,439

- Reaction score

- 777

VFDs are basically three big amplifiers with an adjustable three phase oscillator circuit. The amplifiers are run from a DC power supply which is fed from the single phase supply*.

If all three phases are running at the same power output the draw on the power supply is nearly constant making its job easier.

If you try to draw full power on one phase, you will be asking the transistors in the amplifier for that phase to be doing three times as much work. The draw on the power supply will also fluctuate much more.

Most VFDs will simply not start unless all three phases are connected up.

There are some complications regarding star vs delta wiring and the power factor of induction motors which I've left out to make things simpler.

* in the case of single phase to 3 phase VFDs, which is what we are discussing.

If all three phases are running at the same power output the draw on the power supply is nearly constant making its job easier.

If you try to draw full power on one phase, you will be asking the transistors in the amplifier for that phase to be doing three times as much work. The draw on the power supply will also fluctuate much more.

Most VFDs will simply not start unless all three phases are connected up.

There are some complications regarding star vs delta wiring and the power factor of induction motors which I've left out to make things simpler.

* in the case of single phase to 3 phase VFDs, which is what we are discussing.

malt junkie

Well-Known Member

The reason I've sorta chased this down is I'm thinking of up scaling to a 80-100L 3v over the next few years. My take on the current line up of home brew pumps available; from what we've discussed here, is they are all 20% under powered when used here in Australia. Unless of course you can supply them 60hz, and it seems the easiest way is with a 60hz inverter or geny.

3 phase pumps with VFDs just seem so way over the top for basic brewing tasks on such a small scale. The other option would be to have the motors rewound to deal with the 20% discrepancy; but again costly and a pain in the butt to chase up.

Another reason to hate standards that aren't standard :angry2:

3 phase pumps with VFDs just seem so way over the top for basic brewing tasks on such a small scale. The other option would be to have the motors rewound to deal with the 20% discrepancy; but again costly and a pain in the butt to chase up.

Another reason to hate standards that aren't standard :angry2:

Lyrebird_Cycles

Well-Known Member

- Joined

- 10/7/16

- Messages

- 1,439

- Reaction score

- 777

Rewinding the motor won't change the speed at which the motor runs on 50Hz supply, that depends only on the number of poles.

Synchronous speed in RPM = 60 x Fsupply / number of pole pairs. Induction motors generally run a bit below synchronous speed depending on load. The chugger motor is 2 pole* so it runs about 3500 RPM on 60 Hz and about 2900 RPM on 50 Hz.

If the motor uses a NEMA standard frame, it's probably easier to replace it with a DC motor. DC variable speed is cheap as chips to implement, you just use a mark to space ratio chopper and a cap.

*2 pole= 1 pair of poles.

Synchronous speed in RPM = 60 x Fsupply / number of pole pairs. Induction motors generally run a bit below synchronous speed depending on load. The chugger motor is 2 pole* so it runs about 3500 RPM on 60 Hz and about 2900 RPM on 50 Hz.

If the motor uses a NEMA standard frame, it's probably easier to replace it with a DC motor. DC variable speed is cheap as chips to implement, you just use a mark to space ratio chopper and a cap.

*2 pole= 1 pair of poles.

Lyrebird_Cycles

Well-Known Member

- Joined

- 10/7/16

- Messages

- 1,439

- Reaction score

- 777

Further to the above: looking at the drawing on the Chugger site, the pump looks like it might just be NEMA 42 frame size. This is a bog standard frame size for fractional motors. It's 1/8 HP, that's a little less than 100 watts.

If it is, I'm sure you could get together with someone who knows DC motors (like the guys at Motion Dynamics), import just the head from Chugger and find a >100W DC NEMA 42 motor that runs at around 3500 rpm. The saving on shipping the motor from the US will probably pay for the DC speed control.

If it is, I'm sure you could get together with someone who knows DC motors (like the guys at Motion Dynamics), import just the head from Chugger and find a >100W DC NEMA 42 motor that runs at around 3500 rpm. The saving on shipping the motor from the US will probably pay for the DC speed control.

Yeah, I run a 117l brewery and all on a single KK silver beauty.malt junkie said:The reason I've sorta chased this down is I'm thinking of up scaling to a 80-100L 3v over the next few years. My take on the current line up of home brew pumps available; from what we've discussed here, is they are all 20% under powered when used here in Australia. Unless of course you can supply them 60hz, and it seems the easiest way is with a 60hz inverter or geny.

3 phase pumps with VFDs just seem so way over the top for basic brewing tasks on such a small scale. The other option would be to have the motors rewound to deal with the 20% discrepancy; but again costly and a pain in the butt to chase up.

Another reason to hate standards that aren't standard :angry2:

Not where I'd invest mate. But bigger is cool.

Maybe whirlpool with a pump, then you need much bigger.

malt junkie

Well-Known Member

At that brew length RIMS and HERMS are a very ify proposition or at least the ability to step in good fashion.zorsoc_cosdog said:Yeah, I run a 117l brewery and all on a single KK silver beauty.

Not where I'd invest mate. But bigger is cool.

Maybe whirlpool with a pump, then you need much bigger.

If memory serves me the silver pump you have is an MP RM15 from Aliexpress, I think it was Qldkev who first tracked it down, that was ... 3 years ago, maybe it's time for another forage for a high temp with some balls this time.

malt junkie

Well-Known Member

scooterism

Well-Known Member

- Joined

- 24/10/15

- Messages

- 556

- Reaction score

- 87

I use a Rule 1500 GPH bilge pump for my keg and fermenter day spa.

1500 GPH to Litres is 5678.118, so mega ample pressure.

Plus a 50mm Chinese ebay spray ball.

Works a treat.

It's even heated!

I think Bunnings sell an Ozito pump that is very similar..

1500 GPH to Litres is 5678.118, so mega ample pressure.

Plus a 50mm Chinese ebay spray ball.

Works a treat.

It's even heated!

I think Bunnings sell an Ozito pump that is very similar..

TheWiggman

Haters' gonna hate

Speaking of Kaixin (makers of the ever-trusty Keg King-distributed pump), they have quite a range -

https://kaixinpump.en.alibaba.com/

Their MP-100R is reasonably priced but unfortunately you need to buy minimum 48. I'm not sure if there's a local supplier. Other pumps in the range supply similar head at lower flow rates but order quantities still apply.

https://kaixinpump.en.alibaba.com/

Their MP-100R is reasonably priced but unfortunately you need to buy minimum 48. I'm not sure if there's a local supplier. Other pumps in the range supply similar head at lower flow rates but order quantities still apply.

Hi Guys, I am in a similar boat and looking to purchase a pump for CIP and would appreciate some advise.

I read all the above but dont think im any closer to understanding what will work best for me.

I recently made an order for the following

- ss brewtech 1/2 (64Lt) bbl conical fermenter brewmaster edition.

This comes with a 1/2" CIP spray Ball which i think Operates on 15-100PSI, 40-60PSI is recommended.

SS brewtech have a guide which recommends purchasing something like a 1/4 HP Thermoplastic Submersible Utility Pump but i think i like the idea of a closed loop CIP system.

A guy posted this on homebrewtalk a while back which is kinda of what im after.

So is a Chugger-MAX-Stainless-Head-Nano-Brewery-Pump-230VAC what im after here?

I dont really want to go over $500 for a pump if i can help it.

I read all the above but dont think im any closer to understanding what will work best for me.

I recently made an order for the following

- ss brewtech 1/2 (64Lt) bbl conical fermenter brewmaster edition.

This comes with a 1/2" CIP spray Ball which i think Operates on 15-100PSI, 40-60PSI is recommended.

SS brewtech have a guide which recommends purchasing something like a 1/4 HP Thermoplastic Submersible Utility Pump but i think i like the idea of a closed loop CIP system.

A guy posted this on homebrewtalk a while back which is kinda of what im after.

So is a Chugger-MAX-Stainless-Head-Nano-Brewery-Pump-230VAC what im after here?

I dont really want to go over $500 for a pump if i can help it.

Last edited by a moderator:

Similar threads

- Replies

- 4

- Views

- 2K

- Replies

- 2

- Views

- 1K

- Replies

- 13

- Views

- 4K