You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mill Motors

- Thread starter motiondynamics

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- 23/5/10

- Messages

- 109

- Reaction score

- 31

Hi Guys,

Sorry for the long delay in getting back to you regarding milling motors. Not only has it been hard finding the right motor, I've also been getting busier and busier each month.

Anyway, I'm pleased to say I now have a solution for $169 (which includes GST for those that want to claim back from a scabby govt)

for those that are interested.

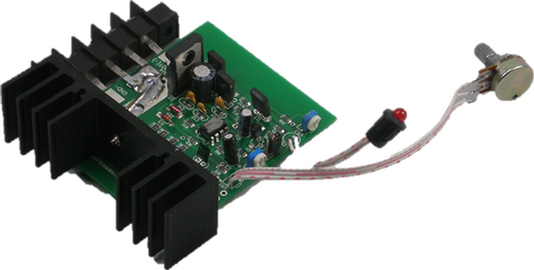

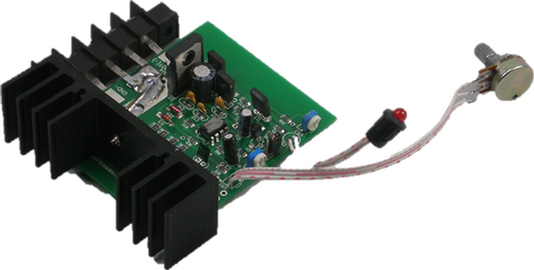

It comprises of a worm drive motor that runs off 12V DC and a DC Speed Control module. The motor uses 12v @ 16A at rated load and with the controller will operate as slow as 1 RPM all the way through to 180 RPM of which I believe (90-120rpm) was the optimum speed you guys wanted. All you have to add the the mix is a coupling to hook from your mill handle to the worm drive shaft. The motor can sit parallel to your milling machine so will look professional and the controller can be mounted virtually anywhere on the machine with the potentiometer (control) able to be mounted wherever you see fit!

The controller is *slightly* different to the one pictured, the pot is not directly connected to the board but is connected via a screw terminal for easier connect/disconnect and the LED is mounted directly to the board.

The powerful motor is capable of delivering up to 20Nm of torque. You could probably crush rocks with this if you chose to, though I dont expect it will be too good for your mill.

It anyone is interested let me know and I'll post better pictures!

Sorry for the long delay in getting back to you regarding milling motors. Not only has it been hard finding the right motor, I've also been getting busier and busier each month.

Anyway, I'm pleased to say I now have a solution for $169 (which includes GST for those that want to claim back from a scabby govt)

for those that are interested.

It comprises of a worm drive motor that runs off 12V DC and a DC Speed Control module. The motor uses 12v @ 16A at rated load and with the controller will operate as slow as 1 RPM all the way through to 180 RPM of which I believe (90-120rpm) was the optimum speed you guys wanted. All you have to add the the mix is a coupling to hook from your mill handle to the worm drive shaft. The motor can sit parallel to your milling machine so will look professional and the controller can be mounted virtually anywhere on the machine with the potentiometer (control) able to be mounted wherever you see fit!

The controller is *slightly* different to the one pictured, the pot is not directly connected to the board but is connected via a screw terminal for easier connect/disconnect and the LED is mounted directly to the board.

The powerful motor is capable of delivering up to 20Nm of torque. You could probably crush rocks with this if you chose to, though I dont expect it will be too good for your mill.

It anyone is interested let me know and I'll post better pictures!

Frag_Dog

Well-Known Member

I'm interested.

What size shaft will the motor take?

What size shaft will the motor take?

- Joined

- 23/5/10

- Messages

- 109

- Reaction score

- 31

I kind of promised when I was here about a year ago that I would find the right motor, so that I did.It just took me a while to get the right thing made in a qty that would make it cheap enough to everyone to be able to enjoy.

http://www.ebay.com.au/itm/12V-DC-29A-350W...=item43a6d9d5a0

Something like this would do the trick, or maybe an old 300-350w power supply from a computer could be adapted. I'm sure people have that kind of stuff just laying about

http://www.ebay.com.au/itm/12V-DC-29A-350W...=item43a6d9d5a0

Something like this would do the trick, or maybe an old 300-350w power supply from a computer could be adapted. I'm sure people have that kind of stuff just laying about

kymba

what?

- Joined

- 14/10/06

- Messages

- 725

- Reaction score

- 11

MastersBrewery

Journeyman, the learning never stops

- Joined

- 7/6/11

- Messages

- 2,319

- Reaction score

- 683

New to the forum, hi guys, feel I know some of you been reading this forum for a while.

Motion Dynamics, been reading this thread with interest although I have a different use I was looking for a motor to stir the mash at 25-30rpm, I supose to be sure this solution would work I'd first have to build the stir paddle and test resistance.

Mike

Motion Dynamics, been reading this thread with interest although I have a different use I was looking for a motor to stir the mash at 25-30rpm, I supose to be sure this solution would work I'd first have to build the stir paddle and test resistance.

Mike

- Joined

- 23/5/10

- Messages

- 109

- Reaction score

- 31

@kymba A Winch motor???? Heh, its a nice thought but if it was that easy I'd have replied to this thread a lot sooner than now!

You can't run a winch motor for more than about a minute or two at a time, then you have to leave it off for an hour to cool down. This motor I've offered here you can run for however long you want.

Its hard to find a suitable powerful motor for mills. They are either too expensive, or have the wrong voltage or not enough torque or the rpm is too low. The only reason I am able to do this is because I don't charge a lot of profit. I had a bulk order for these motors and because the price came to a more affordable amount I just add my lot to the back of the order so that I could help the people here when i said I would find a cheap solution.

Its a fair prie I offer it for. Theres another home seller offering the same motor for a ripoff price of $229 JUST for the gear motor!

@MastersBrewery It would stir mash no problem. 20Nm is a lot of torque, though depending on the thickness you may need to turn the control up a little to get the rpm you want.

@schooey You can pick up, drop in and say hello etc

I'll try and get a better photo of the unit together so you can see, I may even get off my backside and post a video so you can see it all going. Nothing beats seeing something working!

You can't run a winch motor for more than about a minute or two at a time, then you have to leave it off for an hour to cool down. This motor I've offered here you can run for however long you want.

Its hard to find a suitable powerful motor for mills. They are either too expensive, or have the wrong voltage or not enough torque or the rpm is too low. The only reason I am able to do this is because I don't charge a lot of profit. I had a bulk order for these motors and because the price came to a more affordable amount I just add my lot to the back of the order so that I could help the people here when i said I would find a cheap solution.

Its a fair prie I offer it for. Theres another home seller offering the same motor for a ripoff price of $229 JUST for the gear motor!

@MastersBrewery It would stir mash no problem. 20Nm is a lot of torque, though depending on the thickness you may need to turn the control up a little to get the rpm you want.

@schooey You can pick up, drop in and say hello etc

I'll try and get a better photo of the unit together so you can see, I may even get off my backside and post a video so you can see it all going. Nothing beats seeing something working!

stux

Hacienda Brewhaus

- Joined

- 15/12/09

- Messages

- 2,978

- Reaction score

- 310

I'm pleased to say I now have a solution for $169 (which includes GST for those that want to claim back from a scabby govt)

for those that are interested.

I must say I'm mighty interested (not yet to the point of placing an order tho

Can these motors be run in reverse?

Is there a clutch in there to prevent catastrophe with the rock scenario?

So, basically, I imagine you would get a big 12V PSU, mount the motor/gear/coupler on your mill table and a big fat switch?

If the motors were reversible then you could use a DPCO switch to have fwd/off/reverse, a pretty LED, and speed dial all on a nice control box

(reminds me of a shredder)

Is that right?

And how much would a coupler for a MonsterMill 1/2" shaft be?

- Joined

- 23/5/10

- Messages

- 109

- Reaction score

- 31

Can these motors be run in reverse?

Is there a clutch in there to prevent catastrophe with the rock scenario?

So, basically, I imagine you would get a big 12V PSU, mount the motor/gear/coupler on your mill table and a big fat switch?

If the motors were reversible then you could use a DPCO switch to have fwd/off/reverse, a pretty LED, and speed dial all on a nice control box

(reminds me of a shredder)

Is that right?

And how much would a coupler for a MonsterMill 1/2" shaft be?

The motor will run in reverse, the speed control is single direction only, though you could put in a DPDT switch if you wanted to, you just need to be aware of the current. A 12v automotive relay would be better.

There's no clutch, the motor will happily keep spinning regardless. You'd either have to put in a coupling with a clutch in it, or watch what you put into your mill, although from previous responses this isn't a huge problem.

It's as you imagine and you could do exactly as you said, mount it all in a pretty control box.

I don't deal in shafts or couplings, I don't know what the cost would be, though I imagine anyone with a lathe or access to a lathe will be popular.

mfeighan

Well-Known Member

out of curiosity, is its starting current no more than 16 amp? i have stuffed a around with some old psu units and they dont seem to like my compressor, where a small ups battery does it fine.

- Joined

- 23/5/10

- Messages

- 109

- Reaction score

- 31

As soon as I finish this post I'll add the motor and controller to the specials section of the webpage (www.motiondynamics.com.au

I've also made a video, so you can see the motor and controller you get with the package actually working. It's not a great video, so you don't need to tell me this.

The starting current is about ~22A which is also the stall current. Its a good motor and the controller is bullet-proof too. I've sold hundreds of the controllers and never had any issues (apart from user inexperience attempting to draw too much current or bad wiring etc). The motor also had a 20 year accelerated life-cycle test done on it (by the company that bought the bulk qty) and it passed with flying colours.

This controller is the PCB only model which means you can mount it in whatever case you wish.

My goal was to be able to offer the cheapest price for a suitable motor and controller package to give people the option to automate your milling machines for a decent price.

It shouldn't be too hard to couple the output to the mill and I'd really love to see some pictures of how people will set it up when it's finished.

The features of the controller are:

Double Sided, 2 Ounce Copper PCB

Automatic Soft Start, 1.5 second from power on to set speed

Variable Frequency from 300Hz to 3Khz

Voltage: 12V-36V (Jumper Selectable)

0-100% Speed Variation

Constant Torque PWM

2x IRF1405 Mosfets capable of 50A continuous power with peaks up to 75 Amps for 1 minute

Hand Built & Burn Tested Prior to shipping!

Simple to place into your own casing!

Quick Connect Screw Terminals for the wiring connections and a quick connection for the Potentiometer cable!

You can buy online, or come in and pick up.

For those that want more speed and less torque out of a motor (350-400 RPM ~7-8Nm), I can offer something like these motors (ebike) with the same controller which will be cheaper than the worm drive motor.

Ebike Motor 250W

Or

Ebike Motor 350W

Please feel free to compare the prices!

So I'm pretty sure I deserve a beer for this so feel free to bring me one around when you come to buy!

so feel free to bring me one around when you come to buy!

I've also made a video, so you can see the motor and controller you get with the package actually working. It's not a great video, so you don't need to tell me this.

The starting current is about ~22A which is also the stall current. Its a good motor and the controller is bullet-proof too. I've sold hundreds of the controllers and never had any issues (apart from user inexperience attempting to draw too much current or bad wiring etc). The motor also had a 20 year accelerated life-cycle test done on it (by the company that bought the bulk qty) and it passed with flying colours.

This controller is the PCB only model which means you can mount it in whatever case you wish.

My goal was to be able to offer the cheapest price for a suitable motor and controller package to give people the option to automate your milling machines for a decent price.

It shouldn't be too hard to couple the output to the mill and I'd really love to see some pictures of how people will set it up when it's finished.

The features of the controller are:

Double Sided, 2 Ounce Copper PCB

Automatic Soft Start, 1.5 second from power on to set speed

Variable Frequency from 300Hz to 3Khz

Voltage: 12V-36V (Jumper Selectable)

0-100% Speed Variation

Constant Torque PWM

2x IRF1405 Mosfets capable of 50A continuous power with peaks up to 75 Amps for 1 minute

Hand Built & Burn Tested Prior to shipping!

Simple to place into your own casing!

Quick Connect Screw Terminals for the wiring connections and a quick connection for the Potentiometer cable!

You can buy online, or come in and pick up.

For those that want more speed and less torque out of a motor (350-400 RPM ~7-8Nm), I can offer something like these motors (ebike) with the same controller which will be cheaper than the worm drive motor.

Ebike Motor 250W

Or

Ebike Motor 350W

Please feel free to compare the prices!

So I'm pretty sure I deserve a beer for this

Last edited by a moderator:

- Joined

- 14/8/08

- Messages

- 367

- Reaction score

- 30

I found the motor (which I ordered) but I could not find the controller on the specials section.

A combined package might be ideal.

As per my message, please give me a call to get the controller added to the order.

Thanks

Roland

A combined package might be ideal.

As per my message, please give me a call to get the controller added to the order.

Thanks

Roland

- Joined

- 23/5/10

- Messages

- 109

- Reaction score

- 31

I haven't pulled one down, but at a guess, for this torque I'd say the worm would be steel and the drive would be nylon. This is generally how these types of drives are made. When the torque goes up they switch to a copper drive wheel. But they usually use a soft material here to limit noise.

white.grant

tum te tum

- Joined

- 12/3/08

- Messages

- 3,440

- Reaction score

- 23

Looks neat, though I'm wondering if 20nm is going to be enough to run a Mill Master?

cheers

grant

cheers

grant

Mitternacht Brauer

Well-Known Member

- Joined

- 18/10/07

- Messages

- 220

- Reaction score

- 0

Hi John,

I am wondering how much to send motor and drive to 3931 ?

MB

I am wondering how much to send motor and drive to 3931 ?

MB

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 83

- Views

- 12K

- Replies

- 1

- Views

- 2K

- Replies

- 5

- Views

- 1K