You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dedicated Grainfather Guide, Problems and Solutions Thread

- Thread starter HBHB

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

meathead

Well-Known Member

Tap water normal flow, wort slow

However I've read that 20 mins recirc could be the go

However I've read that 20 mins recirc could be the go

postmaster

Well-Known Member

- Joined

- 19/10/14

- Messages

- 59

- Reaction score

- 17

This is what I use for BeerSmith. Whilst the individual Mash and Sparge volumes do not agree, the total volume does agree when the correct preboil litres are put in.

View attachment Grainfather setup for BeerSmith.zip

View attachment Grainfather setup for BeerSmith.zip

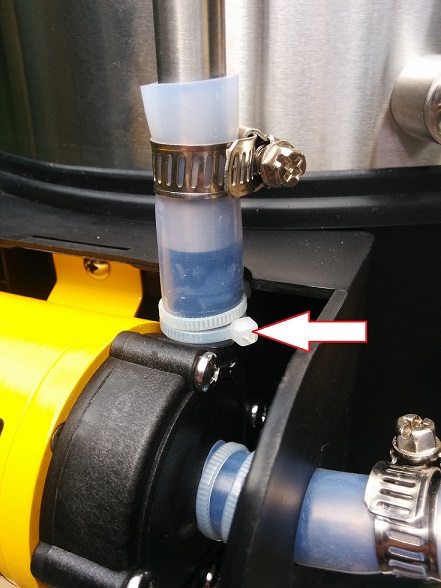

are they using zip ties instead of clamps ?hughbert said:anyone else had issues with leaks on the pump output? Had to remove those and stick a tie on a bit tighter.

is it so no one tightens up a clamp and busts a pump nipple ?

Last few brews we've had some issues with a leak in our chiller around the hexagonal nut adjacent to the part where the red hose is attached. (and the leaks only happen once the chiller has a tap water running through it).

Yesterday we took apart the chiller and found the (white) o-ring for that thread/connect was in very bad shape (it was warped, with hardened bits, and also with fraying bits coming off it).

Without a replacement o-ring we had no option but to put it back together and hope we hadn't made the problem even worse. Once we started using the chiller, the leak was just the same as it had been in the past. We used a towel to stop the leaking water making its way over the edge of the lid and risk it getting back into the wort.

(We've contacted iMake about this, so I'm hoping they'll send a replacement o-ring and that'll fix that problem).

Also, yesterday we had another, separate issue. We started pumping the wort, via the chiller, into a fermenter. About 8L into the transfer the blue hose popped off the chiller and water went everywhere (thankfully mostly over the brewers and the floor. We convinced ourselved that none went back into the wort, but in reality it surely must have). We re-attached the blue hose, made sure the clamp was nice and tight, and continued the transfer with hopefully no serious harm done to the beer.

So check your hose clamps!

Yesterday we took apart the chiller and found the (white) o-ring for that thread/connect was in very bad shape (it was warped, with hardened bits, and also with fraying bits coming off it).

Without a replacement o-ring we had no option but to put it back together and hope we hadn't made the problem even worse. Once we started using the chiller, the leak was just the same as it had been in the past. We used a towel to stop the leaking water making its way over the edge of the lid and risk it getting back into the wort.

(We've contacted iMake about this, so I'm hoping they'll send a replacement o-ring and that'll fix that problem).

Also, yesterday we had another, separate issue. We started pumping the wort, via the chiller, into a fermenter. About 8L into the transfer the blue hose popped off the chiller and water went everywhere (thankfully mostly over the brewers and the floor. We convinced ourselved that none went back into the wort, but in reality it surely must have). We re-attached the blue hose, made sure the clamp was nice and tight, and continued the transfer with hopefully no serious harm done to the beer.

So check your hose clamps!

mrsupraboy

Well-Known Member

I swear ur on the Facebook page lol. Use thread tap over the rubber ur putting on.

hughbert

Member

- Joined

- 8/8/06

- Messages

- 17

- Reaction score

- 4

I have put a hose clamp on now, however you can't put the pump cover back on with a clamp or even a bigger cable tie as it needs a bit of clearance to get up under the black plastic to close.Maheel said:are they using zip ties instead of clamps ?

is it so no one tightens up a clamp and busts a pump nipple ?

better than leaking wort of all over the place tho! This was just testing it out on saturday, i have not made a beer yet.

enoch

Well-Known Member

- Joined

- 29/1/06

- Messages

- 563

- Reaction score

- 55

A very nice ardbir hack at at https://www.facebook.com/pages/Open-Ardbir/606829852720387?fref=nf

Puts my cobbled together version to shame.

Puts my cobbled together version to shame.

Autopilot80

Member

- Joined

- 27/1/13

- Messages

- 14

- Reaction score

- 7

My recirc pipe bracket tacks have let go  . Warranty issues all the way over here in Perth might be problematic.

. Warranty issues all the way over here in Perth might be problematic.

carniebrew

Brewvy baby, brewvy!

- Joined

- 26/11/12

- Messages

- 1,868

- Reaction score

- 614

Yep, assembled mine today and ran a cleaning cycle, noticed a steady drip out of the bottom of the pump cover. Took it apart to see it was coming from exactly where you're highlighting.hughbert said:anyone else had issues with leaks on the pump output? Had to remove those and stick a tie on a bit tighter.

I put another cable tie above the pump cover, near the top of the pump nipple, this stopped it. Have reported to GF to see what they'll say.

carniebrew

Brewvy baby, brewvy!

- Joined

- 26/11/12

- Messages

- 1,868

- Reaction score

- 614

Couple of questions after putting mine together and running a cleaning cycle (and reading 11 pages of this thread!):

1. The pump filter that pushes into the pump inlet seems a bit loose...I've fiddled around with it but I reckon it'll get knocked out really easily during the boil. Anyone having the same issue?

2. Once I'm through the supplied cleaning liquid, I'll start using home-made PBW (70% perc/30% met). Just curious how much PBW people are using in the 7.5 litres of cleaning water? Tablespoon or so?

3. Is anyone putting the mash pipe back into the boiler during the cleaning cycle, or just cleaning it separately?

1. The pump filter that pushes into the pump inlet seems a bit loose...I've fiddled around with it but I reckon it'll get knocked out really easily during the boil. Anyone having the same issue?

2. Once I'm through the supplied cleaning liquid, I'll start using home-made PBW (70% perc/30% met). Just curious how much PBW people are using in the 7.5 litres of cleaning water? Tablespoon or so?

3. Is anyone putting the mash pipe back into the boiler during the cleaning cycle, or just cleaning it separately?

meathead

Well-Known Member

I leave the pipe on and direct it to the walls (of the gf not the kitchen) and clean themcarniebrew said:Couple of questions after putting mine together and running a cleaning cycle (and reading 11 pages of this thread!):

1. The pump filter that pushes into the pump inlet seems a bit loose...I've fiddled around with it but I reckon it'll get knocked out really easily during the boil. Anyone having the same issue?

I've had no probs with this

2. Once I'm through the supplied cleaning liquid, I'll start using home-made PBW (70% perc/30% met). Just curious how much PBW people are using in the 7.5 litres of cleaning water? Tablespoon or so?

I just use Aldi napisan and make sure I rinse well

3. Is anyone putting the mash pipe back into the boiler during the cleaning cycle, or just cleaning it separately?

carniebrew

Brewvy baby, brewvy!

- Joined

- 26/11/12

- Messages

- 1,868

- Reaction score

- 614

Thanks, but I meant the inner basket rather than the recirc pipe.meathead said:I leave the pipe on and direct it to the walls (of the gf not the kitchen) and clean them

meathead

Well-Known Member

Oh in that case I clean it separately while I'm waiting for boil temp

carniebrew

Brewvy baby, brewvy!

- Joined

- 26/11/12

- Messages

- 1,868

- Reaction score

- 614

Cheers. Also, the bottom plate for the inner basket doesn't have any kind of seal around it. And it's a bit concave...any issues with grain leaking underneath it and into the pump during the mash recirculation?

meathead

Well-Known Member

I haven't had any that have bothered me. Perhaps if there is any they drop out after whirlpool or ferment

carniebrew

Brewvy baby, brewvy!

- Joined

- 26/11/12

- Messages

- 1,868

- Reaction score

- 614

Can fellow GF owners tell me how flat their bottom filter plate is? As I mentioned, mine's a bit curved and I'm not sure if that's meant to be, or if it should be flat?

Similar threads

- Replies

- 2K

- Views

- 482K

- Replies

- 9

- Views

- 3K

- Replies

- 44

- Views

- 11K

- Replies

- 483

- Views

- 128K

- Replies

- 20

- Views

- 17K