You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Braumeister NEXTGEN Build

- Thread starter matho

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I'm after some opinions. I'm concerned that the cam lock without arms system that has to be offset from the centre of the urn because of the element won't provide enough support for the malt pipe. Also I want to be able to attach a whirlpool fitting to the same fitting as the malt pipe to use the same pump outlet after the malt pipe has been removed. I wouldn't think the weight of a cam lock with a compression fitting and relatively short length of copper pipe would be sufficient to seal, even if the malt pipe is heavy enough.

If I use elbows to get the pump outlet in the centre of the malt pipe and use two rods to support and clamp down the filter plates (instead of a threaded centre rod like the Braumeister) and then simply screw the malt pipe in using the skin fitting to the pump outlet/main vessel while recirculating, I can then remove the malt pipe, and attach a whirlpool fitting by threading it in (this will be a pipe from the outlet then curved at the top towards the edge to set up a whirlpool). This would be done towards the end of the boil to sanitize then used during cooling with an immerison cooler to speed the cooling process then to whirlpool to allow trub to move to the centre before siphoning to the fermenter.

Can anyone see why this will or won't work? It is very hard to describe in words what I am thinking so I have attached a diagram of what I am now thinking of doing and would appreciate any feedback.

If I use elbows to get the pump outlet in the centre of the malt pipe and use two rods to support and clamp down the filter plates (instead of a threaded centre rod like the Braumeister) and then simply screw the malt pipe in using the skin fitting to the pump outlet/main vessel while recirculating, I can then remove the malt pipe, and attach a whirlpool fitting by threading it in (this will be a pipe from the outlet then curved at the top towards the edge to set up a whirlpool). This would be done towards the end of the boil to sanitize then used during cooling with an immerison cooler to speed the cooling process then to whirlpool to allow trub to move to the centre before siphoning to the fermenter.

Can anyone see why this will or won't work? It is very hard to describe in words what I am thinking so I have attached a diagram of what I am now thinking of doing and would appreciate any feedback.

djar007

Well-Known Member

Interesting design. I am all for clamping down the malt pipe and would be keen hear why the braumeister has designed a malt pipe which when pulled can allow grain to flow through the hole in the centre.An all in one pot with holes in the bottom would stop the flowback of grain when the malt pipe is pulled. I would just say that the simpler the design the better. Adding and removing parts during the process will prove problematic and distract you from concentrating on brewing.

Thanks djar but I'm having trouble understanding what you're saying? I have chosen not to cut out the bottom of this pot because I wanted to avoid drilling extra holes through the main vessel which would be required for the threaded rods. This will be a pot with a false bottom with a flush skin fitting underneath it which will thread directly into the elbow of the main vessel which is attached to the pump. The top filter plate is then attached to a stainless flat bar and then clamped only to the malt pipe using wing nuts. The only holes in the main vessel are pump inlet (skin fitting) and pump outlet (elbow). Everything else is done through the malt pipe, which if it leaks a little bit won't matter.

You probably didn't need that explanation but I'm just not sure what you were saying with the all in one pot and pulling the malt pipe...

You probably didn't need that explanation but I'm just not sure what you were saying with the all in one pot and pulling the malt pipe...

djar007

Well-Known Member

I have trouble understanding me too. Hard to explain and I cant to pictures like you guys can.

I didnt see at first the direction of the pump and now I see that the wort will flow through the top and out through the false bottom. Is that right?

I didnt see at first the direction of the pump and now I see that the wort will flow through the top and out through the false bottom. Is that right?

djar, I had the same question on grain flowing through the bolt down hole on the Braumeister but had a chance to see a real one in operation the other day.

When the malt pipe is lifted onto the draining rack the centre bolt actually remains engaged in the bottom filter so no grain can escape.

I use a small pulley system to lift my malt pipe so I gave it a go on my last brew, not lifting the malt pipe fully out of the main vessel so the bolt hole remained blocked during the sparge. It worked well and virtually no grain escaped after the malt pipe had been fully drained and lifted clear.

When the malt pipe is lifted onto the draining rack the centre bolt actually remains engaged in the bottom filter so no grain can escape.

I use a small pulley system to lift my malt pipe so I gave it a go on my last brew, not lifting the malt pipe fully out of the main vessel so the bolt hole remained blocked during the sparge. It worked well and virtually no grain escaped after the malt pipe had been fully drained and lifted clear.

Pretty pictures are no good if they don't tell the right story! I should have specified. The flow direction is the same as the braumeister. Inlet to pump is on the right, outlet in centre so the flow is up through the grain. I understand your point about the Braumeister now as well! I'm hoping the advantage to my system is the malt pipe is completely separate from the main vessel so there is (hopefully) nowhere for grain to slip through and the filters and top plate are only removed for cleaning at the end of the brew day. I really wish my urn didn't have the element mounted directly in the middle then there would be no need for the S-bend elbows!

My original design had the same malt pipe but using a cam lock in the main vessel and the mating one on the malt pipe but due to the element position in the urn, it would be off to one side which I don't think will give a very good seal as I would have to remove the "arms"

My original design had the same malt pipe but using a cam lock in the main vessel and the mating one on the malt pipe but due to the element position in the urn, it would be off to one side which I don't think will give a very good seal as I would have to remove the "arms"

If you are already putting in holes for the skin fittings... One more for the threaded center rod is not that big a deal, and seems less hole drilling. The only thing it changes is putting holes in the filter plates / bottom of pot in a different location. I have no science to back me but suspect that a closed pot doesn't sparge as well and results in lower efficiency.

You will need an extra plate at the bottom, but it is the easy one - only needs to cover the hole and be able to hold the weight of the grain. I suspect the more open the better actually. Using Craftbrewer 3/8" high durability silicone hose as my seal as per mathos recommendation. Works well.

You will need an extra plate at the bottom, but it is the easy one - only needs to cover the hole and be able to hold the weight of the grain. I suspect the more open the better actually. Using Craftbrewer 3/8" high durability silicone hose as my seal as per mathos recommendation. Works well.

I'm not sure I could make that work in this case. I have a birko exposed element urn which has the element mounted in the centre of the pot so a centre rod is out. I could use two similar to how I'm thinking of doing the malt pipe I suppose. I would also then need to come up with something to keep the bottom plate up off the element. I'm hoping the closed pot will be ok with the domed false bottom to create some space between pump outlet and grain. With the way I'm planning on doing it I can still easily modify it to an open pot later on so I'll try the above plan and let you know how it goes!

Ah, missed that! Kind of important

Sounds like a good plan. I wouldn't rely on being able to seat the malt pipe and screw it into a fitting. At least i think that is what you were saying. It sounds like it could be tough to get in and secure it. Similarly getting another pipe down in the right spot through the wort... I'm not sure how easy that would be. Camlocks lock in. I would guess that is why Arnie did his the way he did. Does he say anything about why on his blog?

Sounds like a good plan. I wouldn't rely on being able to seat the malt pipe and screw it into a fitting. At least i think that is what you were saying. It sounds like it could be tough to get in and secure it. Similarly getting another pipe down in the right spot through the wort... I'm not sure how easy that would be. Camlocks lock in. I would guess that is why Arnie did his the way he did. Does he say anything about why on his blog?

I'm thinking at this stage I'm going to try the camlock sealing and see how it goes. If it doesn't seal well enough with the weight alone I'll clamp it down then if that doesn't work I'll consider cutting the bottom out of the pipe. Then if that doesn't work, I'm going to go for a 3 vessel system since I'll have a lot of the components already. Considering how tight the malt pipe fits in the pot I don't think I'll have much trouble seating it in the camlock or screw fitting but we shall see when I get the parts.

In order to have a threaded rod in the center of the pot and malt pipe and at the same time a camlock sealing I have used a bigger 3/4" camlock and the rod trough it. On the bottom of the main pot a Y fitting is used to connect the pump.

Here some picture that explain better the solution

Already tested with some water and seems OK

http://youtu.be/IOFzzH10K78'> http://youtu.be/IOFzzH10K78

What do you think about?

Davide

Here some picture that explain better the solution

Already tested with some water and seems OK

http://youtu.be/IOFzzH10K78'> http://youtu.be/IOFzzH10K78

What do you think about?

Davide

It looks great running Davide, especially the video with the top filter plate in place. I'm also highly impressed with your DIY Arduino controlled Micro Malt House video, excellent idea!! I think I'll have to order a few more Arduino's to play with :lol:arzaman said:In order to have a threaded rod in the center of the pot and malt pipe and at the same time a camlock sealing I have used a bigger 3/4" camlock and the rod trough it. On the bottom of the main pot a Y fitting is used to connect the pump.

Here some picture that explain better the solution

Already tested with some water and seems OK

http://youtu.be/IOFzzH10K78'> http://youtu.be/IOFzzH10K78

What do you think about?

Davide

[SIZE=10.5pt]Thank you real_beer I[/SIZE]

[SIZE=10.5pt]I have learnt a lot from version 1.0 and from this 2 years reading and evolutions on both in Italian and Australian forum[/SIZE]

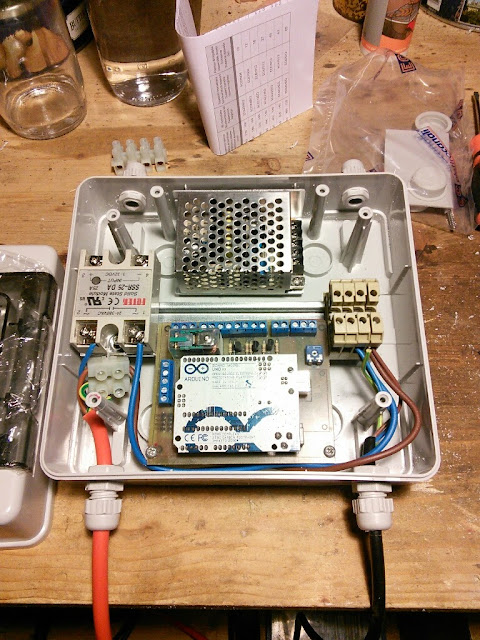

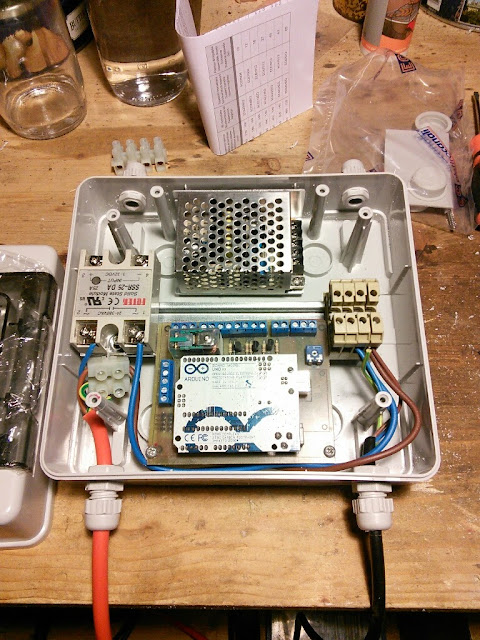

The construction of the clone 2.0 is proceeding very well and I’m now working on the electric part and I have already performed some “wet run” in order to test all the components

Off course the Open ArdBir controller is providing a great improvement to all the process automation and In parallel the Opne ArdBir team has released a new firmware version with some nice new feature and now everything is well documented with an English user manual

Give it a look and discover how powerful is this controller !

[SIZE=10pt]http://goo.gl/W3ZKKb[/SIZE]

[SIZE=10pt]last firmware version can be downloaded here[/SIZE]

[SIZE=10pt]http://goo.gl/nAz2om[/SIZE]

[SIZE=10pt]the FB page for news and announcements

https://www.facebook.com/pages/Open-Ardbir/606829852720387https://www.facebook.com/pages/Open-Ardbir/606829852720387[/SIZE]

[SIZE=10pt]enjoy[/SIZE]

Davide

[SIZE=10.5pt]I have learnt a lot from version 1.0 and from this 2 years reading and evolutions on both in Italian and Australian forum[/SIZE]

The construction of the clone 2.0 is proceeding very well and I’m now working on the electric part and I have already performed some “wet run” in order to test all the components

Off course the Open ArdBir controller is providing a great improvement to all the process automation and In parallel the Opne ArdBir team has released a new firmware version with some nice new feature and now everything is well documented with an English user manual

Give it a look and discover how powerful is this controller !

[SIZE=10pt]http://goo.gl/W3ZKKb[/SIZE]

[SIZE=10pt]last firmware version can be downloaded here[/SIZE]

[SIZE=10pt]http://goo.gl/nAz2om[/SIZE]

[SIZE=10pt]the FB page for news and announcements

https://www.facebook.com/pages/Open-Ardbir/606829852720387https://www.facebook.com/pages/Open-Ardbir/606829852720387[/SIZE]

[SIZE=10pt]enjoy[/SIZE]

Davide

poacher

Active Member

- Joined

- 28/4/13

- Messages

- 32

- Reaction score

- 9

Hi,

Finally got around to wiring my kit controller and have a few questions if someone can please answer.

Have plugged the Arduino to my computer via USB and it does power up but does not recognise it ( should I be reading the program installed ). I am using a mac

I aso plugged into Braumiser shield & screen via USB, the screen powers up but is blank as shown in photo's and does not display temp.

Any help would be greatly appreciated.

Thanks!

Finally got around to wiring my kit controller and have a few questions if someone can please answer.

Have plugged the Arduino to my computer via USB and it does power up but does not recognise it ( should I be reading the program installed ). I am using a mac

I aso plugged into Braumiser shield & screen via USB, the screen powers up but is blank as shown in photo's and does not display temp.

Any help would be greatly appreciated.

Thanks!

djar007

Well-Known Member

Did you add the code to the Arduino mate? And if so have you trimmed the pot to get the brightness correct for you to be able to read screen?

Hi

A common problem is the contrast is turned all the way down. Try adjusting the trimpot on the shield and see if you get characters on LCD.

I assume you bought Arduino from Lael and is therefore preloaded?

Otherwise you will need to download the sketch and compile and download to the Arduino then connect to shield and 12volts. I would suggest not having pump or element connected for the initial testing.

James

Sent from my iPad using Tapatalk HD

A common problem is the contrast is turned all the way down. Try adjusting the trimpot on the shield and see if you get characters on LCD.

I assume you bought Arduino from Lael and is therefore preloaded?

Otherwise you will need to download the sketch and compile and download to the Arduino then connect to shield and 12volts. I would suggest not having pump or element connected for the initial testing.

James

Sent from my iPad using Tapatalk HD

djar007

Well-Known Member

good feeling seeing that isnt it.nice work mate. Also the open ardbir firmware is compatible with this controller.

Similar threads

- Replies

- 15

- Views

- 5K

- Replies

- 13

- Views

- 4K

- Replies

- 9

- Views

- 2K

Equipment For Sale

All grain brewery kit and kegs Gold Coast

- Replies

- 1

- Views

- 1K

Equipment For Sale

For Sale - 3V System in Melbourne -SOLD

- Replies

- 2

- Views

- 2K