randyrob

Halfluck Brewing

- Joined

- 25/10/06

- Messages

- 1,596

- Reaction score

- 7

Bonj is on the money (as usual)

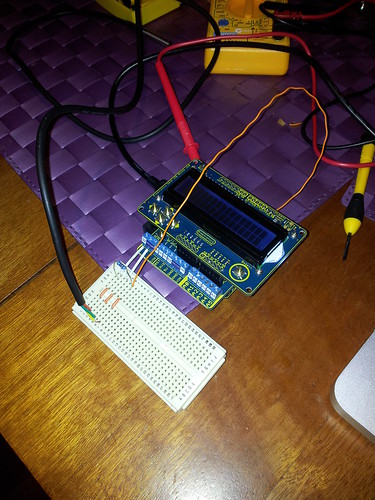

My ones came with this blurb

Output leads: red (VCC), yellow (DATA), green (is) (GND)

The probe of this temperature sensor is DS18B20 original chip

High quality stainless steel tube

Waterproof and corrosion-resistant

Shell size: 6 mm (Diameter), Length of Cable: 100 cm

Power supply range: 3.0V to 5.5V

Temperature range: -55C to +125C (-67F to +257F)

Accuracy: 0.5C (-10C to +85C)

No other components, unique single bus interface

My ones came with this blurb

Output leads: red (VCC), yellow (DATA), green (is) (GND)

The probe of this temperature sensor is DS18B20 original chip

High quality stainless steel tube

Waterproof and corrosion-resistant

Shell size: 6 mm (Diameter), Length of Cable: 100 cm

Power supply range: 3.0V to 5.5V

Temperature range: -55C to +125C (-67F to +257F)

Accuracy: 0.5C (-10C to +85C)

No other components, unique single bus interface