mtb

Beer Bod

- Joined

- 5/1/16

- Messages

- 1,736

- Reaction score

- 1,045

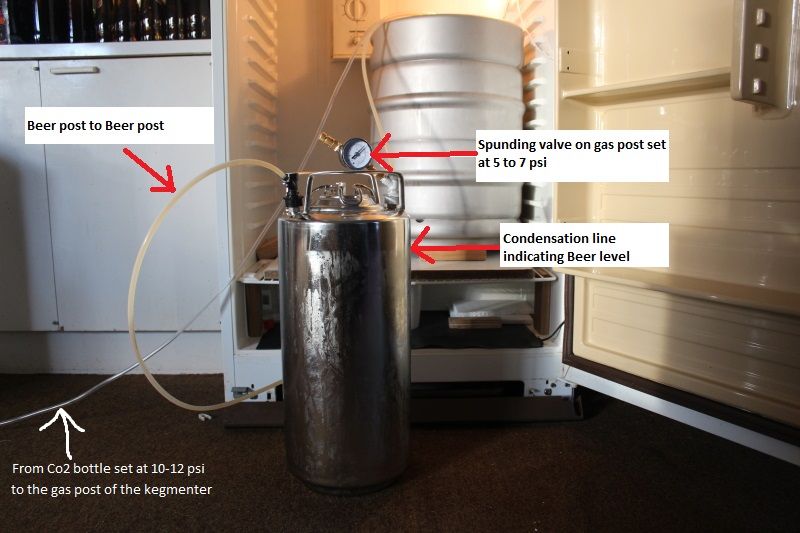

I have a few of these 26L Kegmenters from iBrew (no affiliation but for $180 a pop I'm seriously considering selling my cornies and using these for fermenting as well as dispensing, eliminating the need for keg transfer at all.. but I digress). Currently I ferment in the Kegmenter with a spunding valve set to 10psi @ 18C, so a relatively low carb level, and then transfer to a purged corny keg. When I do a keg transfer using 1m beer line with beer disconnects at both ends, I get excessive foaming in the line - as soon as the beer exits the Kegmenter - and results in excessive foaming in the destination keg.

Items of note;

- Temp of all equipment is relatively equal, ie room temp

- Diameter of beer line is 6mm

- I de-pressurise the Kegmenter and gas it back up to 30kPA, my logic there being that I want to minimise splashing in the destination keg

- I tried upping the pressure in the Kegmenter but this didn't reduce the foaming (not sure why it would but I tried it anyway).

What am I missing? If somebody wants to tell me to simply sell my cornies and buy more Kegmenters, I'll be happy with that as a solution too. SWMBO can't argue with the collective advice of AHB* h34r:

h34r:

*she most certainly will but to no avail

Items of note;

- Temp of all equipment is relatively equal, ie room temp

- Diameter of beer line is 6mm

- I de-pressurise the Kegmenter and gas it back up to 30kPA, my logic there being that I want to minimise splashing in the destination keg

- I tried upping the pressure in the Kegmenter but this didn't reduce the foaming (not sure why it would but I tried it anyway).

What am I missing? If somebody wants to tell me to simply sell my cornies and buy more Kegmenters, I'll be happy with that as a solution too. SWMBO can't argue with the collective advice of AHB*

*she most certainly will but to no avail