Nick JD

Blah Blah Blah

- Joined

- 4/11/08

- Messages

- 7,322

- Reaction score

- 456

Since the Move to All Grain for Thirty Bucks thread has had forty thousand hits I thought it'd be an idea to do a thread about taking it to the next level for those who are still using the technique and haven't moved to bigger vessel BIAB or multi-vessel setups.

Of the other two tutorial threads I've done, I use neither techniques - the 30 Bucks thread was to show the most budget way to trying AG brewing; the 20L tutorial was to show high-gravity brewing and to illustrate a technique where "full sized" batches could be made in the kitchen. So I thought about another thread outlining techniques that over the years I've found work well with StoveTop brewing - especially to those who don't intend to move to a bigger vessel. Most of these methods can easily be scaled up though.

An it's with a heavy heart though that I must inform, there will be no Green Bucket in this thread. Sadly, the Green Bucket has been relegated to vehicle-washing duties and has been tainted with soap residue and as such has been demoted to living in the shed with an old, musty cloth as its only company.

Let's move on.

A Simple Single Decoction Mash for a Bohemian Pilsner.

If you know about decoction mashing then you might as well skip this bit, but if you don't, here's what decoction mashing is:

Taking some of the mash out, boiling the shit out of it, and adding it back to the mash.

That's pretty much it. That, and when you return the boiling mash part back into the mash ... it's going to raise the temperature of the mash. This is a handy thing.

There are long, involved decoction mashing techniques, and they would suit a thread called Advanced Stovetop Techniques, but this isn't that thread - so we'll do a single decoction because it's easy, and achieves what we're after - 1. changing the flavour slightly 2. changing the colour slightly 3. creating more head retention and 4. upping our efficiency.

Here's a bloody graph. At least it's not an equation, but it's handy to describe what is being done.

As you can see, at the start we'll have a short protein rest, then we add some boiling water to bring it up to the sacc rest (the normal mash), then after 45 (I do 60) minutes we scoop a bunch of the mash out and boil the crap out of it - pour it back in the pot, and pull the bag out. Easy.

Enough typing. Time for pictures. Here's some grain.

This grain is a slightly different strain of pilsner grain, and you can really tell by it's flavour. When you drink a good Boh Pils, much of that flavour is actually the grain - I've made a few experimental Ales with it and it's quite incredible how strong-tasting this grain is. You need to get some to do this kind of beer justice.

Here's 3.5kg of it. That's the whole grain bill.

The recipe is:

19L

3.5kg Weyermann Bohemian Pilsner

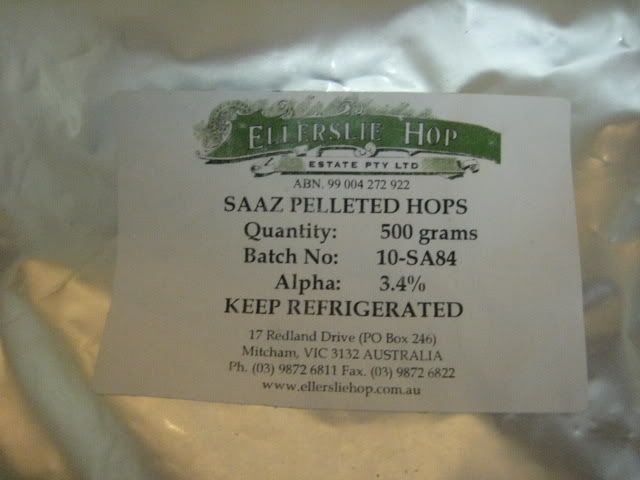

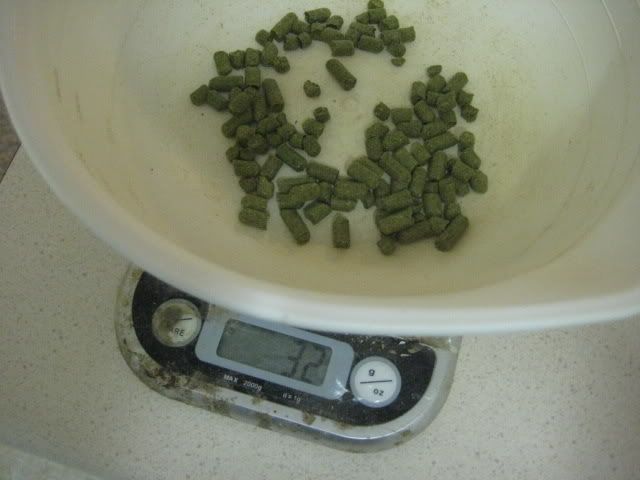

32g Czech Saaz 60min

22g Czech Saaz 30min

17g Czech Saaz 15min

Of the other two tutorial threads I've done, I use neither techniques - the 30 Bucks thread was to show the most budget way to trying AG brewing; the 20L tutorial was to show high-gravity brewing and to illustrate a technique where "full sized" batches could be made in the kitchen. So I thought about another thread outlining techniques that over the years I've found work well with StoveTop brewing - especially to those who don't intend to move to a bigger vessel. Most of these methods can easily be scaled up though.

An it's with a heavy heart though that I must inform, there will be no Green Bucket in this thread. Sadly, the Green Bucket has been relegated to vehicle-washing duties and has been tainted with soap residue and as such has been demoted to living in the shed with an old, musty cloth as its only company.

Let's move on.

A Simple Single Decoction Mash for a Bohemian Pilsner.

If you know about decoction mashing then you might as well skip this bit, but if you don't, here's what decoction mashing is:

Taking some of the mash out, boiling the shit out of it, and adding it back to the mash.

That's pretty much it. That, and when you return the boiling mash part back into the mash ... it's going to raise the temperature of the mash. This is a handy thing.

There are long, involved decoction mashing techniques, and they would suit a thread called Advanced Stovetop Techniques, but this isn't that thread - so we'll do a single decoction because it's easy, and achieves what we're after - 1. changing the flavour slightly 2. changing the colour slightly 3. creating more head retention and 4. upping our efficiency.

Here's a bloody graph. At least it's not an equation, but it's handy to describe what is being done.

As you can see, at the start we'll have a short protein rest, then we add some boiling water to bring it up to the sacc rest (the normal mash), then after 45 (I do 60) minutes we scoop a bunch of the mash out and boil the crap out of it - pour it back in the pot, and pull the bag out. Easy.

Enough typing. Time for pictures. Here's some grain.

This grain is a slightly different strain of pilsner grain, and you can really tell by it's flavour. When you drink a good Boh Pils, much of that flavour is actually the grain - I've made a few experimental Ales with it and it's quite incredible how strong-tasting this grain is. You need to get some to do this kind of beer justice.

Here's 3.5kg of it. That's the whole grain bill.

The recipe is:

19L

3.5kg Weyermann Bohemian Pilsner

32g Czech Saaz 60min

22g Czech Saaz 30min

17g Czech Saaz 15min