You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dedicated Herms Guide, Problems And Solution Thread

- Thread starter chappo1970

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

dmac80

Well-Known Member

- Joined

- 10/12/08

- Messages

- 217

- Reaction score

- 14

hsb,

Your leds will need to go from switched active to neutral, the same as your pump and heaters.

Have you earthed your steel enclosure? Couldn't see from your pictures whether you had or not.

If you aren't sure it would be best to get an electrician to check it out for you.

Cheers

Your leds will need to go from switched active to neutral, the same as your pump and heaters.

Have you earthed your steel enclosure? Couldn't see from your pictures whether you had or not.

If you aren't sure it would be best to get an electrician to check it out for you.

Cheers

Hi dmac

Enclosure is earthed. Door/Enclosure runs to Earth Bus.

The Hex Element is also earthed to its plug.

I'm also running the whole setup through an RCD for extra security.

I don't know what "switched active to neutral" means?

I have used only the live wiring to run switches and LEDs and relay.

The Neutral/Earth runs direct to Sockets for all devices.

I'm hoping I'm close to correct wiring, the deeper you dig the more my limits are exposed with 240v.

I understand all advice proferred is not a substitute for professional assessment by a qualified sparky.

If anyone had a previously created schematic to share, that'd be great, or further advice to see me right. Thanks for your patience.

Enclosure is earthed. Door/Enclosure runs to Earth Bus.

The Hex Element is also earthed to its plug.

I'm also running the whole setup through an RCD for extra security.

I don't know what "switched active to neutral" means?

I have used only the live wiring to run switches and LEDs and relay.

The Neutral/Earth runs direct to Sockets for all devices.

I'm hoping I'm close to correct wiring, the deeper you dig the more my limits are exposed with 240v.

I understand all advice proferred is not a substitute for professional assessment by a qualified sparky.

If anyone had a previously created schematic to share, that'd be great, or further advice to see me right. Thanks for your patience.

dmac80

Well-Known Member

- Joined

- 10/12/08

- Messages

- 217

- Reaction score

- 14

hsb,

Try this schematic, it will indicate when your heating elements have power and gives you a manual override on your HEX, which i'm assuming you want.

View attachment img_5170814_0001.pdf

Cheers

Edit: Just re read your post, if you want to be able to switch off your HEX, just delete the wiring from the first contact on the HEX which bypasses the SSR.

Try this schematic, it will indicate when your heating elements have power and gives you a manual override on your HEX, which i'm assuming you want.

View attachment img_5170814_0001.pdf

Cheers

Edit: Just re read your post, if you want to be able to switch off your HEX, just delete the wiring from the first contact on the HEX which bypasses the SSR.

Thanks guys, got it sorted. LEDs wired in parallel, control panel is working perfectly. Needed a bit of help getting over the line there.

I've deleted my original posts above, which glaab and dmac were kind enough to reply to, lest anyone should look to them for electrical advice!

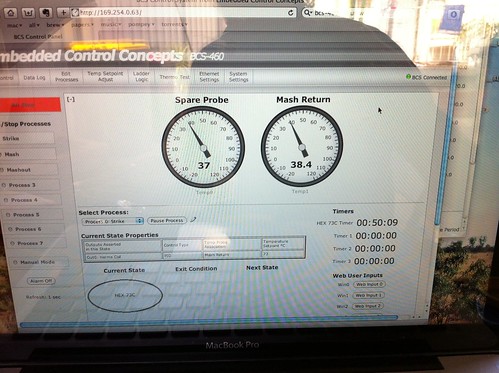

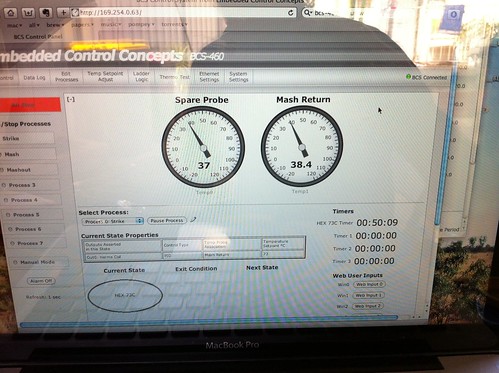

So I've done a test run of my newborn 4v HERMS which has a Control Panel containing a BCS-460/SSR to do the magic stuff.

Ramped up 40L, I'd normally heat strike water using my over-the-side immersion, but thought it'd be a good test.

My only problem was priming my pump. Realised my HLT pickup was letting air in but a few tweaks, bit of tape and the pump is flying too. Forgot to save my BCS log, will try and remember when I fire it up 'in anger' in the coming weeks.

Here's some pictures of it, the Heat Exchanger came from Stainless Stuff, who was great to deal with and happy to accomodate any changes to the design.

The stand is $100 of pine with some giant carriage bolts, courtesy of Botany Timber, who were nice enough to throw in a free bottle of decking oil as well. It probably won't resale as bespoke quality furniture, but it's solid as a rock and I'm happy with the outcome, especially with no router/circular saw/workbench or vice, quality dodgy handcraftmanship.

My boil kettle isn't in shot, I just mashout to a bucket, drain to kettle and boil on an italian spiral burner. Didn't see the need, for me, to accommodate it into the brew stand.

I've enjoyed the process but would not recommend it to anyone looking to save time and money!

A few odds and ends left to do, will probably lag the tubing and might relocate the control panel a bit higher up, but all in all it's about time I made some fracking beer after months of messing around making this!!!

I've deleted my original posts above, which glaab and dmac were kind enough to reply to, lest anyone should look to them for electrical advice!

So I've done a test run of my newborn 4v HERMS which has a Control Panel containing a BCS-460/SSR to do the magic stuff.

Ramped up 40L, I'd normally heat strike water using my over-the-side immersion, but thought it'd be a good test.

My only problem was priming my pump. Realised my HLT pickup was letting air in but a few tweaks, bit of tape and the pump is flying too. Forgot to save my BCS log, will try and remember when I fire it up 'in anger' in the coming weeks.

Here's some pictures of it, the Heat Exchanger came from Stainless Stuff, who was great to deal with and happy to accomodate any changes to the design.

The stand is $100 of pine with some giant carriage bolts, courtesy of Botany Timber, who were nice enough to throw in a free bottle of decking oil as well. It probably won't resale as bespoke quality furniture, but it's solid as a rock and I'm happy with the outcome, especially with no router/circular saw/workbench or vice, quality dodgy handcraftmanship.

My boil kettle isn't in shot, I just mashout to a bucket, drain to kettle and boil on an italian spiral burner. Didn't see the need, for me, to accommodate it into the brew stand.

I've enjoyed the process but would not recommend it to anyone looking to save time and money!

A few odds and ends left to do, will probably lag the tubing and might relocate the control panel a bit higher up, but all in all it's about time I made some fracking beer after months of messing around making this!!!

fraser_john

Go Pies

Nice,

just watch the HEX when you have it "on" rather than auto, even on auto, with no wort flowing, the sensor reads like it needs to heat the HEX, so it goes about its business and ends up boiling!

This has happened about four times to me now, it is easy to get distracted by the sparge, recirculating, mash ph, sparge ph, wort gravity, chatting to other brewers on IRC etc etc etc.

I have a standard PID that I plan on putting in my HEX that will stop it from heating past 95c by adding in another SSR between the soak/ramp mash PID and the HEX, so regardless of what the mash PID is trying to do, the secondary PID will prevent boils.

Just a matter of finding time.

just watch the HEX when you have it "on" rather than auto, even on auto, with no wort flowing, the sensor reads like it needs to heat the HEX, so it goes about its business and ends up boiling!

This has happened about four times to me now, it is easy to get distracted by the sparge, recirculating, mash ph, sparge ph, wort gravity, chatting to other brewers on IRC etc etc etc.

I have a standard PID that I plan on putting in my HEX that will stop it from heating past 95c by adding in another SSR between the soak/ramp mash PID and the HEX, so regardless of what the mash PID is trying to do, the secondary PID will prevent boils.

Just a matter of finding time.

vykuza

Well-Known Member

- Joined

- 12/5/09

- Messages

- 1,024

- Reaction score

- 237

Here's some pictures of it, the Heat Exchanger came from Stainless Stuff, who was great to deal with and happy to accomodate any changes to the design.

HSB it looks the goods. Now time to make some beer!

Out of interest, what changes did you make to the design of the HEX from Stainless stuff?

Re: Boiling HEX, thanks, good tip. My LED is wired so it'll show me whenever the HEX is active so in theory

Might see if I can use the BCS to effect the same outcome - ie; never boil.

The BCS is a great bit of gear, I'm loving it already. The 'On' HEX state was a 'just in case', I don't intend using it unless there's a BCS problem.

The HEX design is, I think, originally John's (above.) My only changes were fittings and location of coil within but Emmanuel (SS Stuff guy) was happy to work with whatever.

The only change I could retrospectively think of for now is addition of a nut on base to make Earthing easier and maybe a slight change to base so it drains 100%, I am left with a couple of mm of water due to flat bottom and slight recess around element. The lid is also a bit of a PITA and could be better, I just tend to lie if over the top rather than fit it on.

Might see if I can use the BCS to effect the same outcome - ie; never boil.

The BCS is a great bit of gear, I'm loving it already. The 'On' HEX state was a 'just in case', I don't intend using it unless there's a BCS problem.

The HEX design is, I think, originally John's (above.) My only changes were fittings and location of coil within but Emmanuel (SS Stuff guy) was happy to work with whatever.

The only change I could retrospectively think of for now is addition of a nut on base to make Earthing easier and maybe a slight change to base so it drains 100%, I am left with a couple of mm of water due to flat bottom and slight recess around element. The lid is also a bit of a PITA and could be better, I just tend to lie if over the top rather than fit it on.

Used my all-new HERMS rig last night, knocked out a Gale's HSB clone (recipe from Wheeler CAMRA book)

Was like a scene out of Bladerunner with this thing whirring and gurgling and bleeping away in the garden, strange green light and steam spewing out. And yes, I did that laundry as well :wub:

Was like some kind of guilty pleasure sitting there while it did it's thing. No major issues, recirculation was easy, just set and forget.

My only problem is the constraint of crap house wiring that means I can only run HEX or Immersion Heater at any one time, meaning my Strike water is going cold whilst I mash. So was a 20minute lag when I made 2nd water addition (post-mashout) as the temp recovered from 56C back to 76C. Not sure if that will effect the end product? Didn't take an OG as yet. I no chill so it's stashed for later.

I could leave the grain dry and steaming and recirculate the HLT to mashout temperature before adding water to Mash if it makes a difference.

My schedule was:

- Heat HLT with Immersion to Strike temp

- Dough in. Roughly 66C.

- HEX on. Recirculate 90min at 66C

- HEX raise to Mashout - 76C. 1st Runnings.

- HEX off. Add more water.

- HEX on. Recirculate 10min at 76C (took 20 minutes to get from 56 to 76, so this step takes 30 minutes)

- HEX off. Mashout. 2nd Runnings.... boil/hops/cube etc...

Any tips from experienced HERMSALAITES welcomed

Anyway, all in all chuffed to bits that it works. Recirculating rocks, get around 1C a minute recirculating, pump (March 815) seems easily able to handle running at full tilt using my 1/2" plumbing.

Was like a scene out of Bladerunner with this thing whirring and gurgling and bleeping away in the garden, strange green light and steam spewing out. And yes, I did that laundry as well :wub:

Was like some kind of guilty pleasure sitting there while it did it's thing. No major issues, recirculation was easy, just set and forget.

My only problem is the constraint of crap house wiring that means I can only run HEX or Immersion Heater at any one time, meaning my Strike water is going cold whilst I mash. So was a 20minute lag when I made 2nd water addition (post-mashout) as the temp recovered from 56C back to 76C. Not sure if that will effect the end product? Didn't take an OG as yet. I no chill so it's stashed for later.

I could leave the grain dry and steaming and recirculate the HLT to mashout temperature before adding water to Mash if it makes a difference.

My schedule was:

- Heat HLT with Immersion to Strike temp

- Dough in. Roughly 66C.

- HEX on. Recirculate 90min at 66C

- HEX raise to Mashout - 76C. 1st Runnings.

- HEX off. Add more water.

- HEX on. Recirculate 10min at 76C (took 20 minutes to get from 56 to 76, so this step takes 30 minutes)

- HEX off. Mashout. 2nd Runnings.... boil/hops/cube etc...

Any tips from experienced HERMSALAITES welcomed

Anyway, all in all chuffed to bits that it works. Recirculating rocks, get around 1C a minute recirculating, pump (March 815) seems easily able to handle running at full tilt using my 1/2" plumbing.

NickB

I haven't had a C**t all night, Drinkstable....

- Joined

- 29/6/06

- Messages

- 4,436

- Reaction score

- 191

See if you can run an extension cable (preferably a good quality one rated to 10A) to another outlet on a separate circuit.

Most likely you'll have a 16A or 20A circuit. If that's the case, isolate what points this circuit runs, and what's plugged into them. If you're lucky, you may get away with it.

If not, maybe get a dedicated 20A or 32A circuit run to your brewing area. Prices may vary depending on what sparky you use, and wether he's an AHB member or not

Cheers

PS: Blingy lights mate, mine will hopefully look something like that soon h34r:

h34r:

Most likely you'll have a 16A or 20A circuit. If that's the case, isolate what points this circuit runs, and what's plugged into them. If you're lucky, you may get away with it.

If not, maybe get a dedicated 20A or 32A circuit run to your brewing area. Prices may vary depending on what sparky you use, and wether he's an AHB member or not

Cheers

PS: Blingy lights mate, mine will hopefully look something like that soon

mxd

Well-Known Member

- Joined

- 26/10/09

- Messages

- 2,431

- Reaction score

- 208

My only problem is the constraint of crap house wiring that means I can only run HEX or Immersion Heater at any one time, meaning my Strike water is going cold whilst I mash. So was a 20minute lag when I made 2nd water addition (post-mashout) as the temp recovered from 56C back to 76C. Not sure if that will effect the end product?

on your next run, can you see how often then the HX is actually taken power ?

If it's "off" for a "period" of time, you could possibly look at wiring some logic in that will send power to the HLT when the HX doesn't require it ?

some more things that may assist, run a 1200W element in the HLT that you use when your using the HX (you should get 16 amps out of a 10 amp line).

or, with a bit more "start-up" time.

Fill HLT, heat to 80ish.

put the required amount of water in the MLT and then start running the HX (initially set the temp to +5 ??), when the MLT is at temp, dough in and then set the HX back to mash temp.

Hopefully by the time you doing a mash out, the temp in the HLT would have only dropped 5-10 degrees.

Looks great by the way.

Matt

Thanks guys, some good ideas there.

I will investigate the Fuse Box a bit more and see exactly what I do have.

Both my H/Ex and Immersion are around 9A, so maybe I could get away with it, that running both won't work is an untested assumption on my part.

Otherwise I could flick between H/Ex and Immersion, or rejig my brewday a bit. I suppose I could just let the mash sit, whilst I recirc my strike water too. Decisions decisions!

It is on wheels so I could just wheel it down the street looking for power sources, loose lamppost covers lol. Mobile brew cart, will swop power for beer.

I will investigate the Fuse Box a bit more and see exactly what I do have.

Both my H/Ex and Immersion are around 9A, so maybe I could get away with it, that running both won't work is an untested assumption on my part.

Otherwise I could flick between H/Ex and Immersion, or rejig my brewday a bit. I suppose I could just let the mash sit, whilst I recirc my strike water too. Decisions decisions!

It is on wheels so I could just wheel it down the street looking for power sources, loose lamppost covers lol. Mobile brew cart, will swop power for beer.

fraser_john

Go Pies

I use a "normally closed" SSR to manage the HEX/HLT issue. When the HEX is on, the HLT element is off, when the HEX is off, the HLT element is on. Both are managed by PIDs. I can run my system now from a standard 10amp circuit.

mateostojic

Well-Known Member

- Joined

- 18/8/09

- Messages

- 56

- Reaction score

- 0

I use a "normally closed" SSR to manage the HEX/HLT issue. When the HEX is on, the HLT element is off, when the HEX is off, the HLT element is on. Both are managed by PIDs. I can run my system now from a standard 10amp circuit.

I am currently designing my HERMS control box as well. The design uses two 16A circuits and it would be really useful if i could use the principle that you mentioned here. I have tried to understand how this works but i cant figure it out. Do you think i could trouble you for a quick circuit diagram which shows how you use the normally closed SSR to run the HEX and HLT elements?

Cheers

Mate

NickB

I haven't had a C**t all night, Drinkstable....

- Joined

- 29/6/06

- Messages

- 4,436

- Reaction score

- 191

I use a "normally closed" SSR to manage the HEX/HLT issue. When the HEX is on, the HLT element is off, when the HEX is off, the HLT element is on. Both are managed by PIDs. I can run my system now from a standard 10amp circuit.

Sounds like the plan if you either a. Don't have the option of using multiple house circuits (as an example, the two bedroom place we are currently in has only 2 x 16A circuits. I manage to run a 2200W HLT and a 1600W HEx off these no problems) or b. don't have the capacity to either run a dedicated circuit, or upgrade the current RCDs to a higher rating (16A to a 20A for example - This is assuming that a correct or higher gauge existing cable is sufficient to run a higher Amp circuit - consult a qualified electrician to verify!).

One question FJ - does your setup add significant time to your brewday? I only ask, as my HLT seems to be running fairly constantly from mash-in to mash-out (however this could just be the HLT liquor reaching set-point, turning off, and then dropping below set-point again... I tend to be tasked with other 'important things' to do on a brew day....)?

Cheers

fraser_john

Go Pies

One question FJ - does your setup add significant time to your brewday? I only ask, as my HLT seems to be running fairly constantly from mash-in to mash-out (however this could just be the HLT liquor reaching set-point, turning off, and then dropping below set-point again... I tend to be tasked with other 'important things' to do on a brew day....)?

Not at all, with a 2400w (10 amp draw) element and a 90 minute mash schedule, the HLT has almost dedicated use of the circuit after the mash program has reached set point and heats to 76c in about 30 minutes. I have never been left waiting for the HLT waiting to heat.

Do you think i could trouble you for a quick circuit diagram which shows how you use the normally closed SSR to run the HEX and HLT elements?

Image

Original concept by Kirem, many thanks to his hints and tips during the control case build.

Similar threads

- Replies

- 18

- Views

- 2K

- Replies

- 70

- Views

- 6K

- Replies

- 2K

- Views

- 396K