Got a weekend night to myself away from SWMBO so started noodling around in the shed and by late evening got stuck into pulling the drill press out of storage and reassembling it.

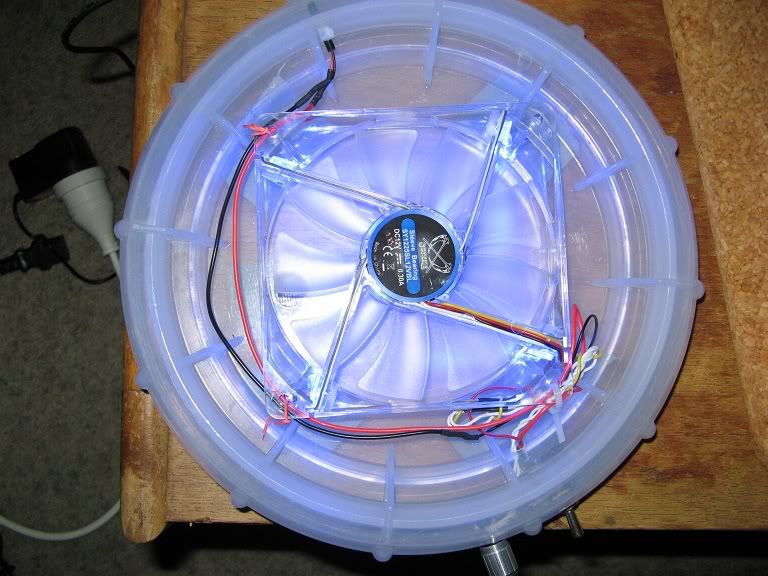

Prototype 240Volt AC Stirplate.

Cooling holes on all sides, large venting holes below.

I have ditched the top for now as will use either clear acrylic top or simple idea of using a rubbermaid or tupperware style container, square in place of the lid. The Flask sits in the tupperware container which is a spill containment receptacle in case of excessive foaming.

I have to go look at plastic containers and see how much if at all they depress under different weights to build the magnetic disc height to get the magnets right up against the plastic container while not touching. This should get the magnets up close as possible to the flask while keeping them as far away from the fan as possible.

Full 240 Volt Shaded Pole Fan controlling Triac with 240Volt switch and noise suppression circuitry.

I have a conduit box I will cut down to make a sealed environment in which to do all the wiring. Thinking about a silicone seal around the Triac compression fittings.

As you can see this is a monster fan with enough guts to pull through some large batches. Not a bad eBay buy at $14 compared to Jar Car.

View attachment 26847