michael_aussie

Well-Known Member

- Joined

- 12/4/10

- Messages

- 928

- Reaction score

- 5

IMO I wouldn't use an STC1000 to directly control a 10A load for extended periods.Fellas

I've tacked this onto this thread - as it is sort of on topic

I'm gonna wire one of these up to control a 2400W element

I've got a 3m extension lead that I was planning to use - its 1.0mm2 cable rated to 10A 2400W

Is this adequate for extend use (over a brewday) or should I be looking at 1.5mm2 flex cable due to the load?

Cheers

The internal relays of the STC1000 are rated to 10A, but ... I wouldn't run a 10A load directly off the unit.

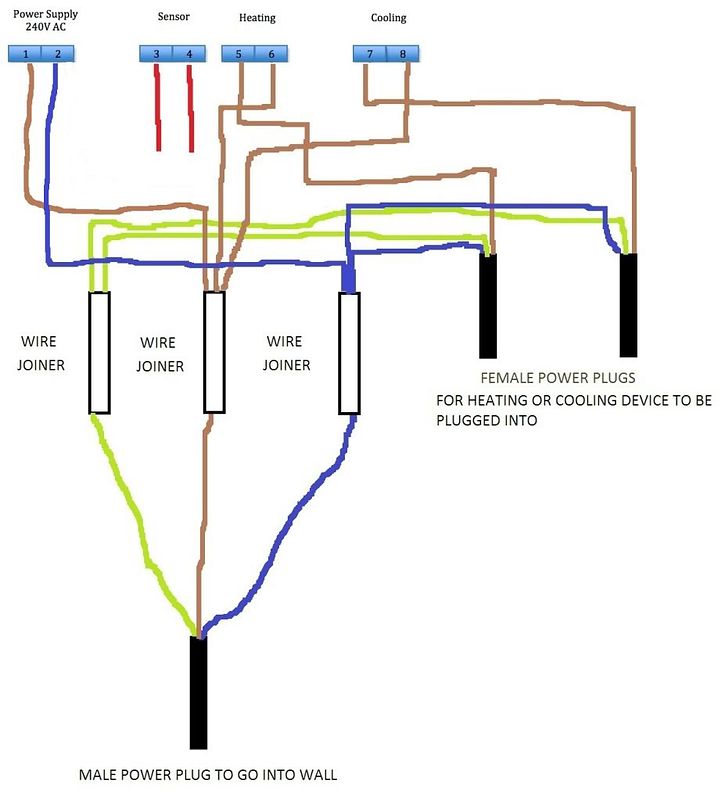

I would wire an external relay to the output and wire the load to the external relay.

Relays are dirt cheap, and this will ensure your STC1000 has a longer life.

The extension lead is OK, but once again, if you are going to go to the trouble of setting this all up for the long term, 1.5mm will do a better job and really isn't that more expensive.

2 bobs worth.