reVoxAHB

Well-Known Member

- Joined

- 3/3/07

- Messages

- 1,112

- Reaction score

- 17

Hi Fellas, looking for direction here. The boss at work handed me down an old motor used in our auger. It's Italian with the following specs:

It looks like:

M: 80/ACS HP: 1 N:0394

kW: 0,75 min-1: 1700

V: 240 A: n/a Hz 60

V: 450l n/a uF: n/a Ser: S1

IP 55 COS: 0,99 CL: F

Does this min -1@ 1700 indicate the motor runs at 1700 rpm?

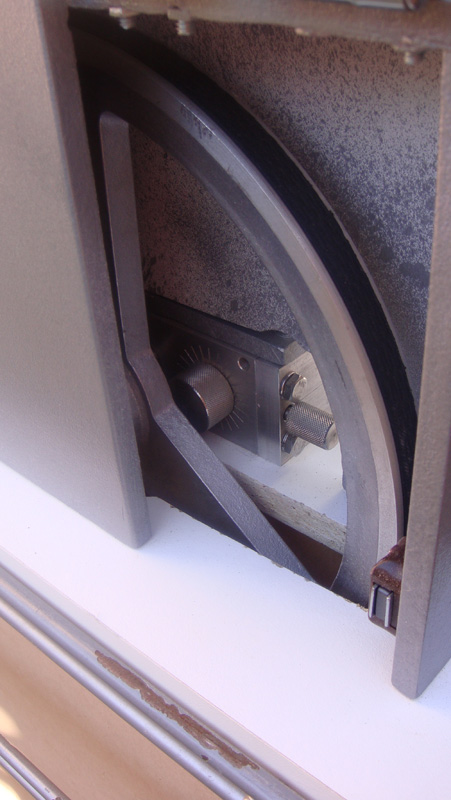

He's motorised my MashMaster MillMaster using a 3 1/2" drive pulley and 9" pulley on the mill:

Where I reckon it's driving way too fast. From other threads, I've come to understand that slower speed and higher torque is the go. And I've noticed many are using 1" and 12" pulleys on the MillMaster

It looks like:

M: 80/ACS HP: 1 N:0394

kW: 0,75 min-1: 1700

V: 240 A: n/a Hz 60

V: 450l n/a uF: n/a Ser: S1

IP 55 COS: 0,99 CL: F

Does this min -1@ 1700 indicate the motor runs at 1700 rpm?

He's motorised my MashMaster MillMaster using a 3 1/2" drive pulley and 9" pulley on the mill:

Where I reckon it's driving way too fast. From other threads, I've come to understand that slower speed and higher torque is the go. And I've noticed many are using 1" and 12" pulleys on the MillMaster