I emailed Frank at MashMaster for some advice about how to measure the mill gap and what he would recommend as a starting point for an ideal crush. 0.6mm seems pretty narrow but I guess the fluted rollers are completely different to the knurled rollers. I was very impressed with the detail in his reply. I should stress that Mashmaster is not recommending a specific mill gap, rather each Brewer needs to find the correct crush that suits the grain and set up they are using. Thanks Mashmaster.

Here is the reply:

Hi Chris

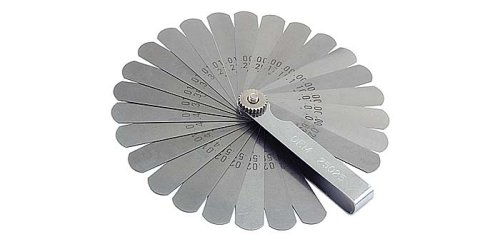

Short answer, feeler gauges and about 0.6mm to be on the safe side.

Long answer:

I might ask a couple of the home brew stores that sell pre-ground malt what setting they are using with the new rollers which reflects their home brew shop crush. I have actually designed a couple things into the flutes to provide a limit maximum limit of flour that you can produce, with the old knurled rollers you could adjust them way above what you would want for brewing, with the fluted rollers you will get about 10% (full sieve set including 100 mesh) or 15% (short stack no 100 mesh) max in the pan. ASBC ideal is 5%, British Mash Tun 10% (Brits are more practical less theoretical) most commercial 2, 4 and 8 roller mills around the 7-11%. Looking at the top end sieve course particle size I would start around 0.4 mm or 0.5mm as a gap setting that is close as the briess normal grind and commercial roller mills, but such grinds may still be too fine for most people systems. If you have a look at the Rock Port Brewery study in the link courser may actually get you greater efficiency. Just to make it a little more confusing I can also change the grist distribution without changing the gap by altering the running speed of the mill, the fluted rollers are less RPM dependent than the knurled rollers (between 200 and 500RPM) I did not test any higher RPMs because I dont recommend milling that fast at slower speeds down to about 120RPM there was not a big change less than 2-3% variation statistically non significant but much more exhausting because I had to hand turn the mill instead of drill power.

But still if you take RPMs in account it makes it harder again to recommend a gap setting. Other variables moisture contend of the malt and humidity. Wet milling is a totally different story again. I used to many years ago recommend a gap setting for one of my mills and I actually received the odd email of complaint that customers had a stuck sparge so I am just reluctant to offer my opinion based on my system. If I can get some info from the home brew shops to see what their shop grind is like I will publish the data, and no doubt it will not be long until users are out publishing their own experiences on the net.

Feeler gauges are useful if you want to measure the gap but honestly I would not bother for brewing unless you are using somebody’s recommendations that have the same system as you and running at about the same RPM (between 200-500 the fluted rollers will change distribution pattern 2-4% depending at what pan/sieve your looking at. I have measured gap settings at 0.1mm increments and done a full sieve analysis but only because I was looking at trend lines distribution patterns for a brewer go course loose a bit efficiency (or maybe gain it according to the rockport brewery study in the link below) as opposed to stuck sparge and slow launter speed.