Hey all,

I have been thinking about constructing a flow hood for a while, as my second-floor Sydney inner-west rental residence is just not the place to play with yeast.

I am wondering if many Aussies have constructed their own on the cheap? If you have, I'd love to see pics.

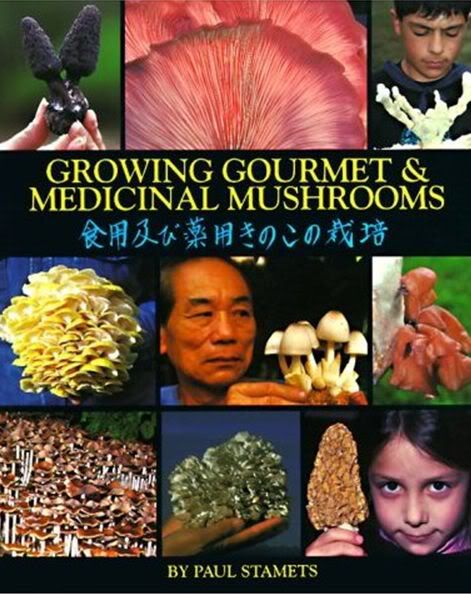

I was reading up on this the other night and found this online, and realised that I actually had this edition sitting on my shelf, and had not paid attention to that article as I had bought it as a set. Anyway, the author talks about using a cheap air purifier caulked onto a tub.

The most attractive air purifiers I have seen are the Honeywell ones with replaceable HEPA filters, but these are still about $150 and expensive to ship from the US. My tentative idea is to get something like this and place a bank of computer fans behind it to create sufficient positive pressure. See attached diagram.

I would appreciate any input from anyone that know something about aerodynamics. I have this, which I thought was a great source, but I would like to know if it could be done with smaller sized filters.

Cheers

Dan

I have been thinking about constructing a flow hood for a while, as my second-floor Sydney inner-west rental residence is just not the place to play with yeast.

I am wondering if many Aussies have constructed their own on the cheap? If you have, I'd love to see pics.

I was reading up on this the other night and found this online, and realised that I actually had this edition sitting on my shelf, and had not paid attention to that article as I had bought it as a set. Anyway, the author talks about using a cheap air purifier caulked onto a tub.

The most attractive air purifiers I have seen are the Honeywell ones with replaceable HEPA filters, but these are still about $150 and expensive to ship from the US. My tentative idea is to get something like this and place a bank of computer fans behind it to create sufficient positive pressure. See attached diagram.

I would appreciate any input from anyone that know something about aerodynamics. I have this, which I thought was a great source, but I would like to know if it could be done with smaller sized filters.

Cheers

Dan