_HOME_BREW_WALLACE_

Professional Drunken Yahoo!

- Joined

- 30/6/09

- Messages

- 1,365

- Reaction score

- 68

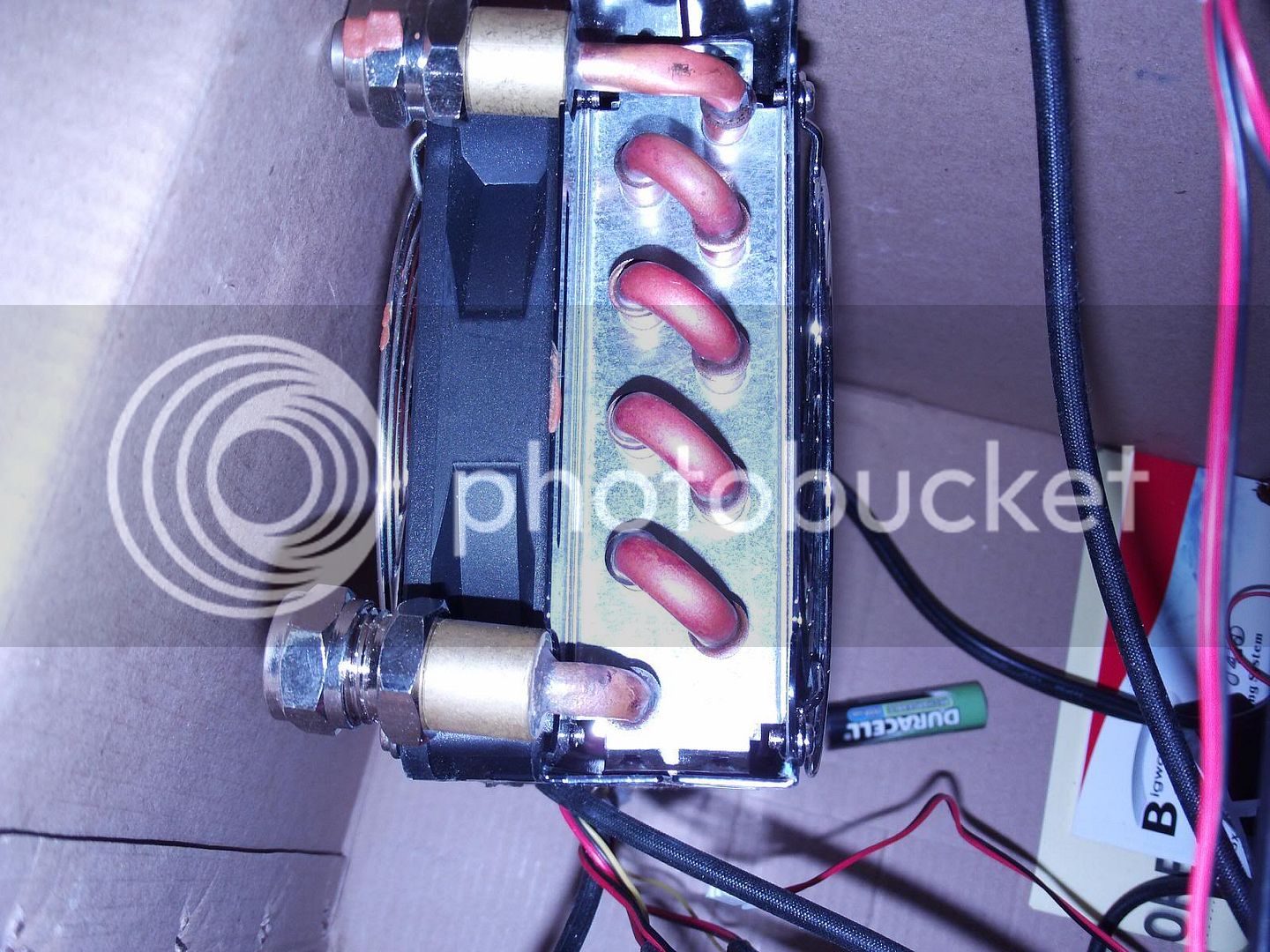

Hey guys, playing around with a couple of wort cooling ideas today. but before i go into too much detail, is is possible to cool the wort TOO quickly? If so what will it do to the beer?

_W_

_W_