dent

Under Pressure

- Joined

- 20/6/08

- Messages

- 954

- Reaction score

- 467

Yank:yeah there are reports that this is great for almost all styles - I have only just started so if still be a while before I have any first hand examples.

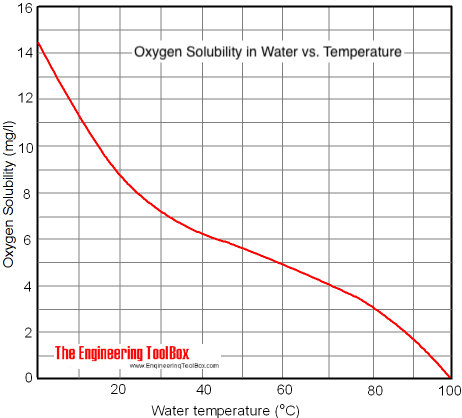

Tugger: Thanks for the info - I am boiling the water to remove the DO and adding some metabisulfite to get rid of what remains. The vacuum I am using is to purge air from the grist and mash tun, and to allow me to cleanly flush out this and other vessels. I considered the CO2 removal methods like you say but I figured it would use up a prohibitive amount of gas.

Tugger: Thanks for the info - I am boiling the water to remove the DO and adding some metabisulfite to get rid of what remains. The vacuum I am using is to purge air from the grist and mash tun, and to allow me to cleanly flush out this and other vessels. I considered the CO2 removal methods like you say but I figured it would use up a prohibitive amount of gas.