The sticker and website says they're made by Wenzhou Kaixin Pumps Co. Ltd, and the brochure I got calls them "Kaixin" so that's a much better name than " Chinese 240v Food Grade Magnetic Drive Pump".

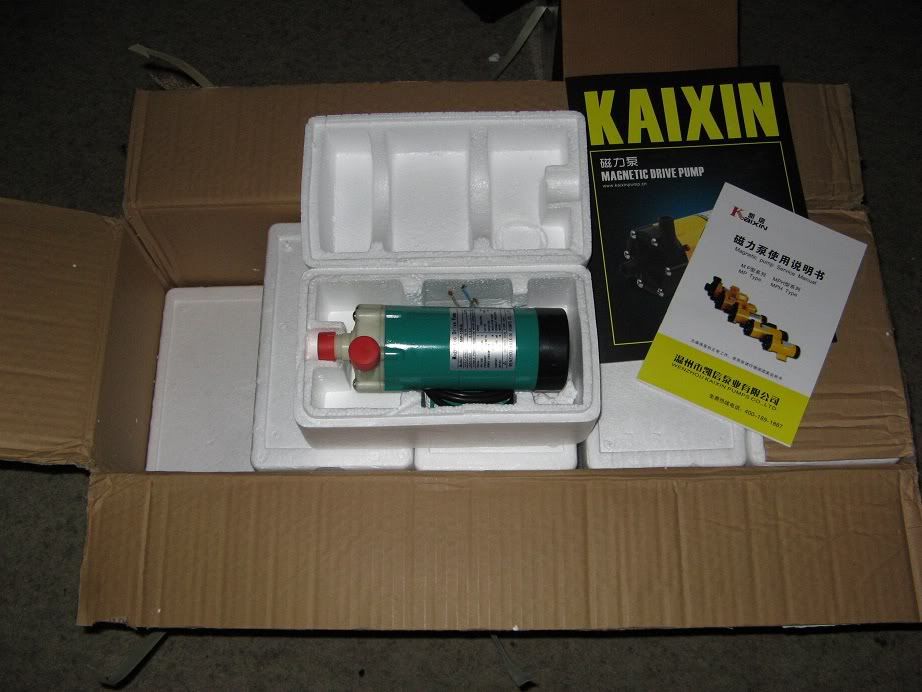

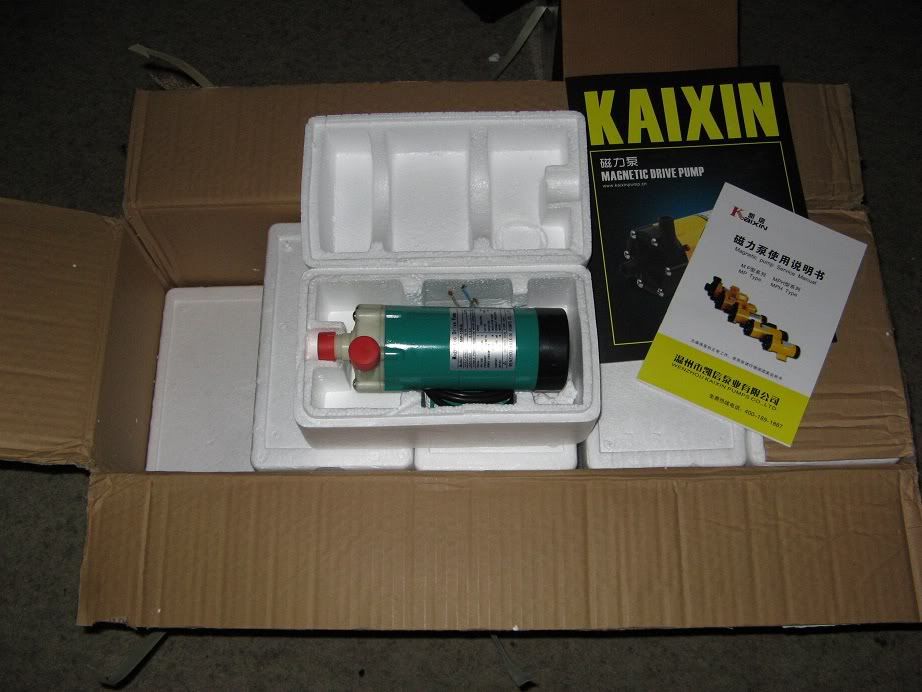

There are a number of similar looking pumps on Alibaba, sold on Ebay and in LHBS, and to confuse matters more it appears that many are OEM/rebranded. After several weeks worth of emails (to various vendors) I purchased the pumps for the Bulk Buy from Wenzhou Kaixin via their Alexpress Store. Once the order was placed and paid for, the pumps arrived at my doorstep (shipped via DHL) within a week:

The website currently lists the MP-15RM at US$28.58 which makes them comparable in price to the little brown solar pumps.

Shipping is $30-40 for individual orders, but bulk-buy or shared shipping should reduce the shipping costs to somewhere around $15-20 each.

The MP-15RM pump that I ordered for myself looks like this:

The brochure and website all show yellow-body pumps, since I wanted a pump with 1/2 inch threaded fittings the older stock green-body pumps were supplied, the new ones say they have 3/4 inch fittings.

The Kaixin pump's housing and impeller is made from is 'food grade' polypropylene, however the manufacturer does not rate them for use for pumping water at 100degC, instead suggesting they should only be used up to 80degC.

Specification sticker on the MP-15RM:

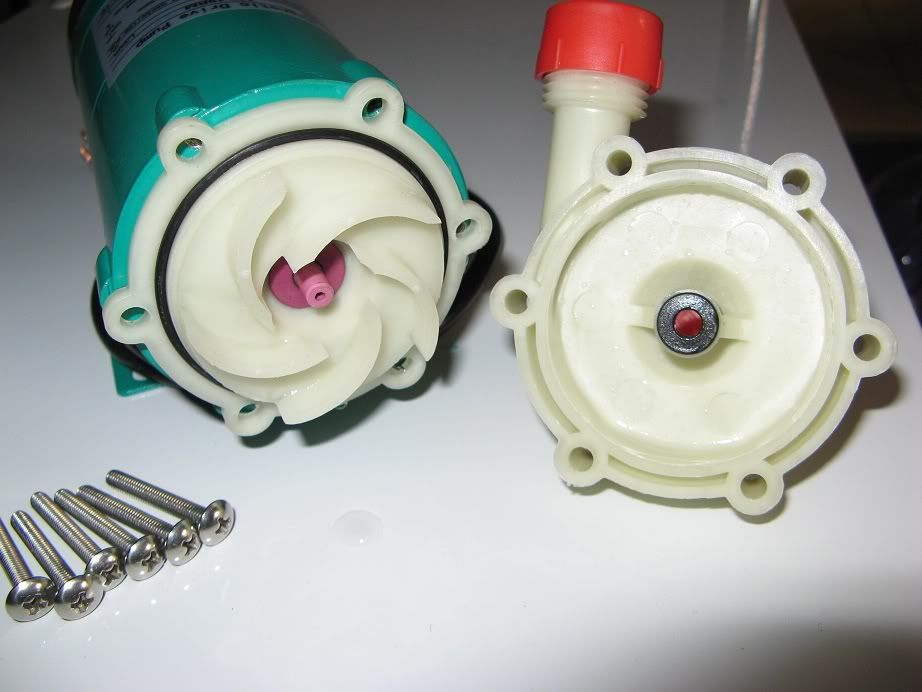

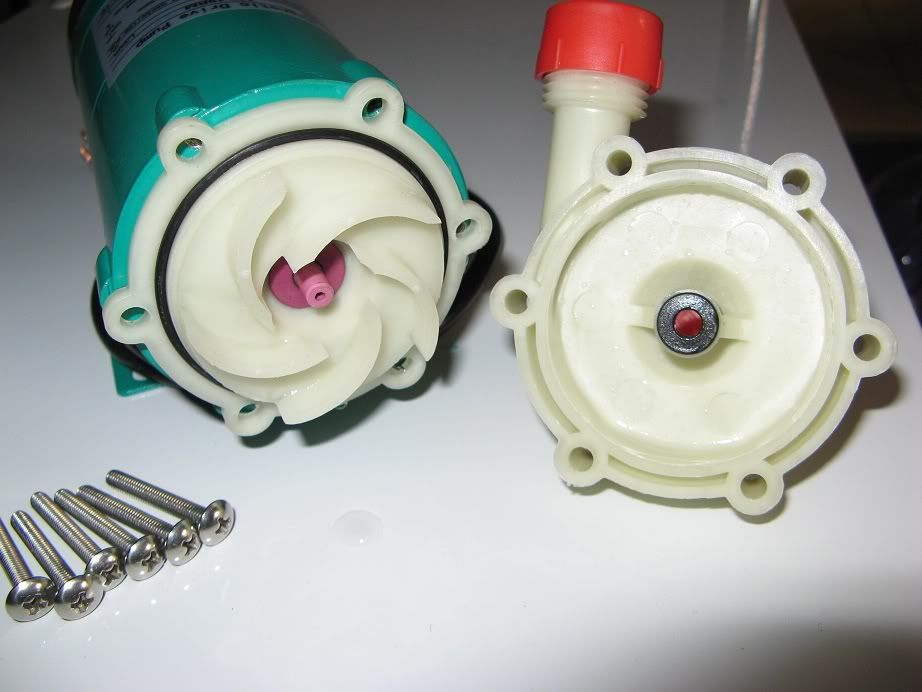

After unscrewing the 6 bolts on the front:

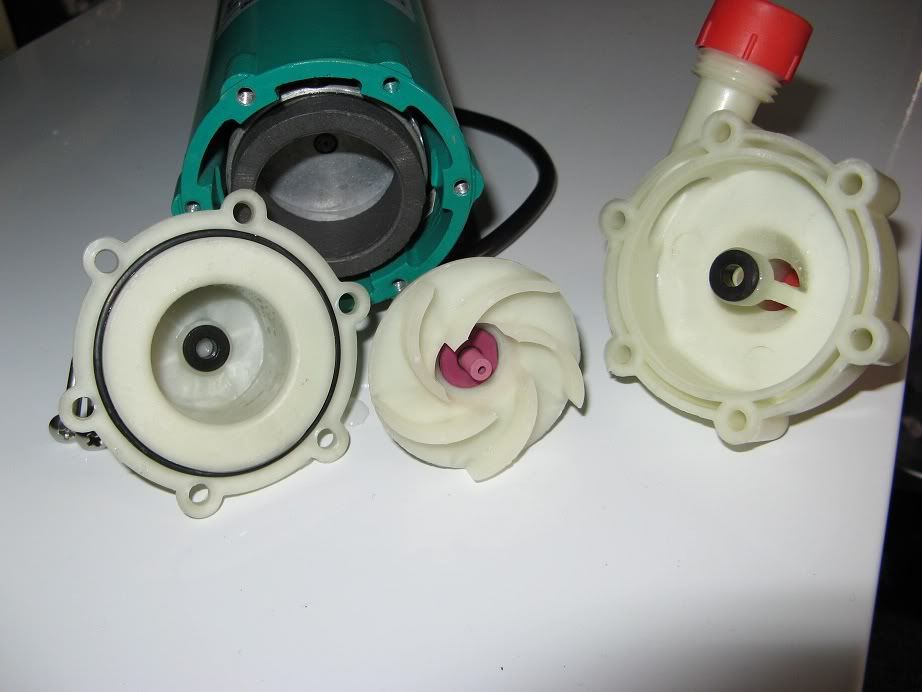

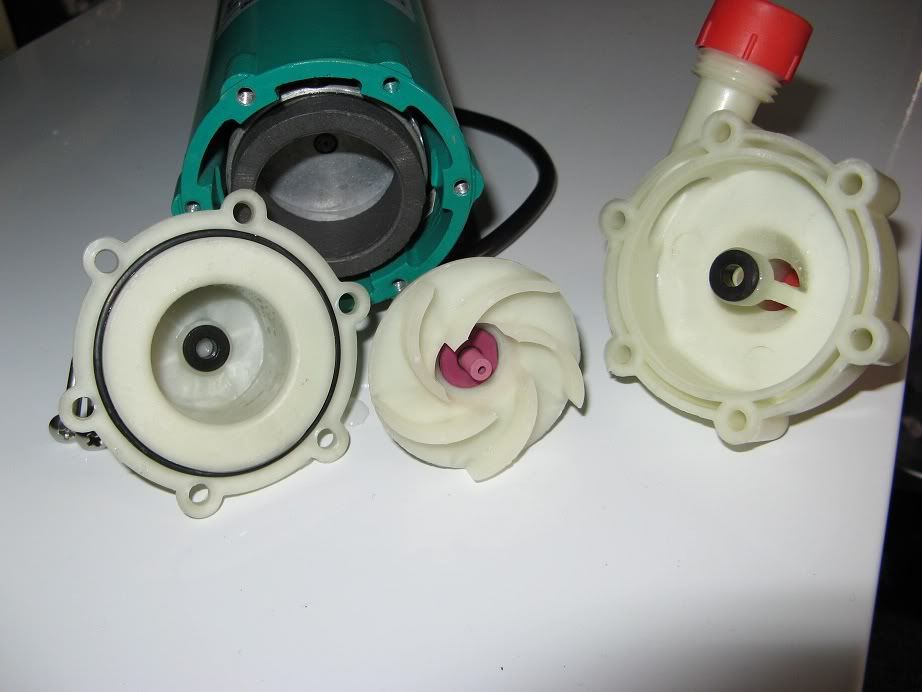

.. and removing the impeller/housing:

Since they are actual magnetic drive pumps, they should be much easier to clean and maintain than the little brown solar pump, which I've found tends to get grunge around the impeller shaft and then stops working.

Setup and ready to go:

The thread on the intake port was quite 'tight' (slightly oversized) for the US-supplied camlock fitting so it required some force to get it on more than a couple of turns (which might not be a good thing with a plastic pump housing).

I had already started brewing (with the little brown solar pump) when the Kaixin pumps arrived today, but had one wired up in time for cleaning up.

Here is the flow rate from the ground to the top of my keggle (approx 1m):

Compared to the little brown solar pump:

From the bottom of my brewstand to the top of the HLT (approx 1.5m):

The pumps are very well priced, appear to be well made and seem to work well (so far). Time will tell how they work and last when pumping wort and how they go (or if, or or how long they work for) when operating with boiling wort/water.

There are a number of similar looking pumps on Alibaba, sold on Ebay and in LHBS, and to confuse matters more it appears that many are OEM/rebranded. After several weeks worth of emails (to various vendors) I purchased the pumps for the Bulk Buy from Wenzhou Kaixin via their Alexpress Store. Once the order was placed and paid for, the pumps arrived at my doorstep (shipped via DHL) within a week:

The website currently lists the MP-15RM at US$28.58 which makes them comparable in price to the little brown solar pumps.

Shipping is $30-40 for individual orders, but bulk-buy or shared shipping should reduce the shipping costs to somewhere around $15-20 each.

The MP-15RM pump that I ordered for myself looks like this:

The brochure and website all show yellow-body pumps, since I wanted a pump with 1/2 inch threaded fittings the older stock green-body pumps were supplied, the new ones say they have 3/4 inch fittings.

The Kaixin pump's housing and impeller is made from is 'food grade' polypropylene, however the manufacturer does not rate them for use for pumping water at 100degC, instead suggesting they should only be used up to 80degC.

Specification sticker on the MP-15RM:

After unscrewing the 6 bolts on the front:

.. and removing the impeller/housing:

Since they are actual magnetic drive pumps, they should be much easier to clean and maintain than the little brown solar pump, which I've found tends to get grunge around the impeller shaft and then stops working.

Setup and ready to go:

The thread on the intake port was quite 'tight' (slightly oversized) for the US-supplied camlock fitting so it required some force to get it on more than a couple of turns (which might not be a good thing with a plastic pump housing).

I had already started brewing (with the little brown solar pump) when the Kaixin pumps arrived today, but had one wired up in time for cleaning up.

Here is the flow rate from the ground to the top of my keggle (approx 1m):

Compared to the little brown solar pump:

From the bottom of my brewstand to the top of the HLT (approx 1.5m):

The pumps are very well priced, appear to be well made and seem to work well (so far). Time will tell how they work and last when pumping wort and how they go (or if, or or how long they work for) when operating with boiling wort/water.

Last edited by a moderator: