5150

Well-Known Member

Hi Guys,

I'm just in the process of building a new brew stand and rig and I was after everyone's feedback, good and bad.

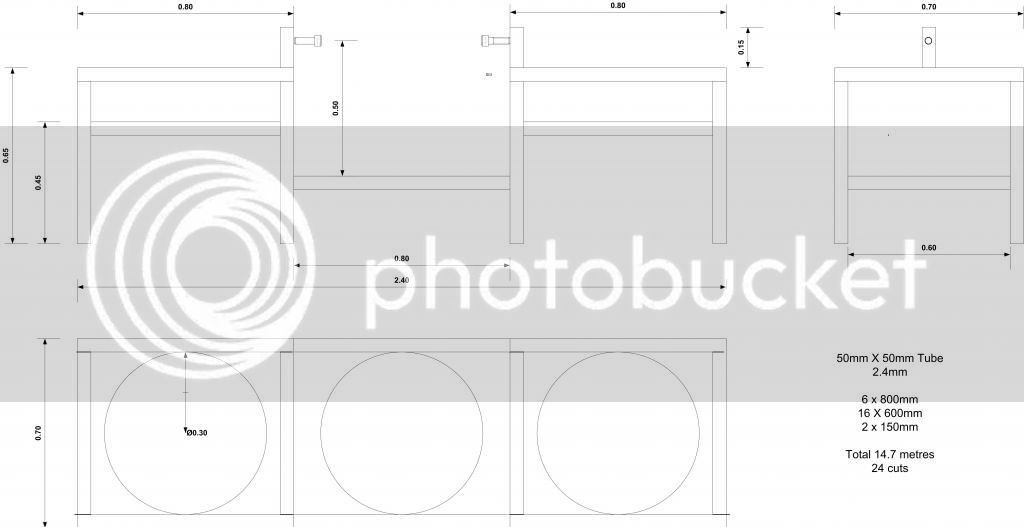

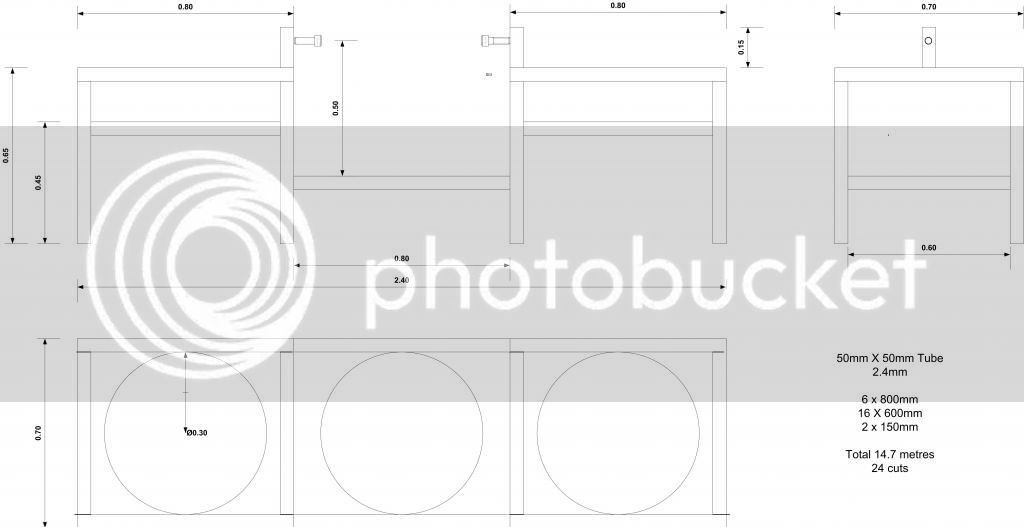

A bit of about what I am after is a stand to hold three 150 Liter stainless pots. The mash tun will be suspended half way up and 150mm to the front to allow me to tip the kettle over 90° to make it a little easier to clean and empty when I make big beers. It'll just be made from 50x50mm 2.4mm steel tube. I'm just going to go square cut as I can get the local shop to cut it for me as apposed to me having to buy a drop saw to cut all my 45°.

Anyway, I hope the image appears below as I just opened a photo bucket account just for this. :unsure:

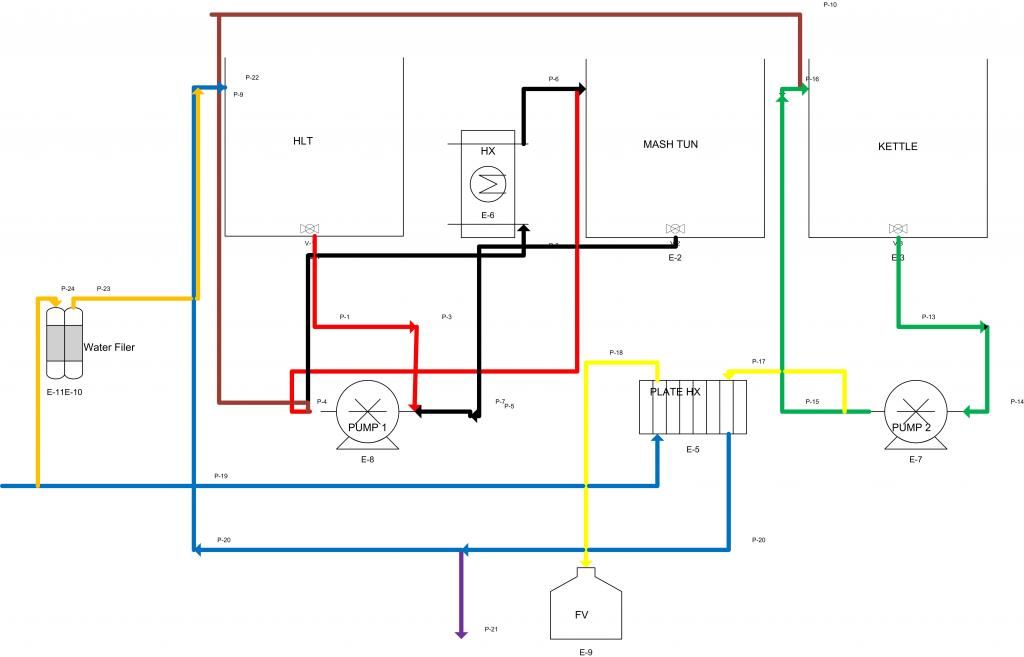

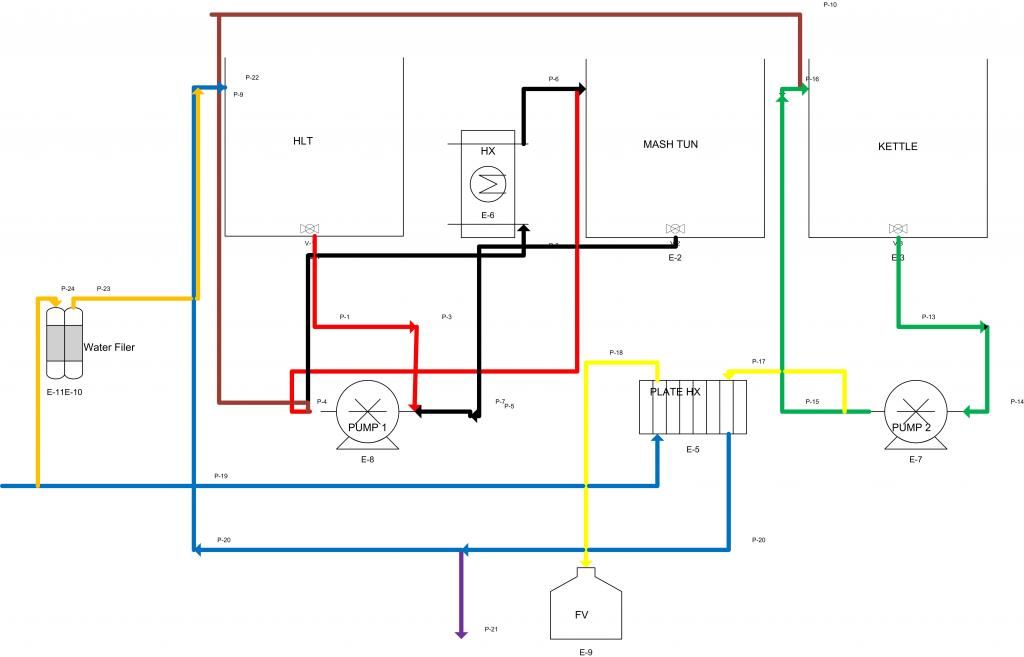

As long as these images are appearing here is a pic of the plumbing I am thinking. Sorry the above image and this one is pretty basic. Everything is plumbed so that I don't have to move hoses etc while brewing. I feel like there is a ridiculous amount of hoses and plumbing, so please be as harsh as you like. Also wondering peoples opinion of plumbing with copper/Stainless as apposed to silicon??? I know it will have to do with cleaning.

Thanks in advance guys.

If my images didn't work here are the links to images.

I'm just in the process of building a new brew stand and rig and I was after everyone's feedback, good and bad.

A bit of about what I am after is a stand to hold three 150 Liter stainless pots. The mash tun will be suspended half way up and 150mm to the front to allow me to tip the kettle over 90° to make it a little easier to clean and empty when I make big beers. It'll just be made from 50x50mm 2.4mm steel tube. I'm just going to go square cut as I can get the local shop to cut it for me as apposed to me having to buy a drop saw to cut all my 45°.

Anyway, I hope the image appears below as I just opened a photo bucket account just for this. :unsure:

As long as these images are appearing here is a pic of the plumbing I am thinking. Sorry the above image and this one is pretty basic. Everything is plumbed so that I don't have to move hoses etc while brewing. I feel like there is a ridiculous amount of hoses and plumbing, so please be as harsh as you like. Also wondering peoples opinion of plumbing with copper/Stainless as apposed to silicon??? I know it will have to do with cleaning.

Thanks in advance guys.

If my images didn't work here are the links to images.