You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Design of 150L Brew stand and Plumbing

- Thread starter 5150

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

There are conventional symbols for all the parts in a plumbing circuit, they make the job of laying out and reading system designs easier and quicker, there are a bunch on Wikipedia that can be copied and pasted.

By convention in on the left/top and out on the right/bottom and pumps are always drawn with the flow from left to right.

Personally if this was your first big rig build I would build the system and run it with flexible connections (hoses) and slowly replace them with hard plumbing once I was certain exactly where and to what I wanted my connections.

its very important with hard plumbed system to make sure all the pipes and vessels self drain. otherwise you are creating traps for bacteria or left over cleaning chemicals. A grade of about 1 diameter/ 300 mm of run for 15mm pipes larger pipes can be a bit flatter (in the old money we would have said 1/2" 1D/foot 3/4"-1" about 1D/2 foot and 11/4"-2" 1 D/Yard)

The pumps need to be down low so they are self priming to avoid air bubbles and cavitation.

A bit more on pumps, well the valves near pumps, on the inlet side of the pump all valves should be full bore and only used in the fully open position, all control valves should be on the outlet side of the pump.

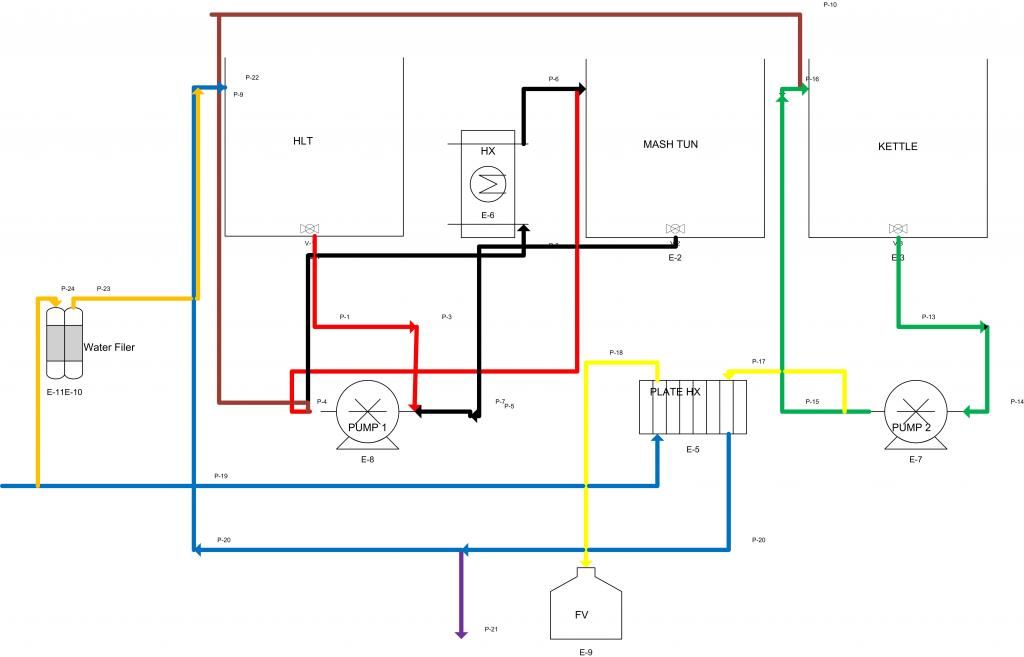

Plate and frame heat exchangers are the most commonly identified seat of infection in breweries. it is imperative that you be able to clean your HEx thoroughly, the best way is to be able to put some water/cleaner in the kettle and recirculate it through the HEx and back to the kettle, and that you recirculate boiling water through the loop for at least 10 minutes - you have plenty of time to do this while mashing - your circuit design as it stands doesn't allow this.

Have fun

Mark

By convention in on the left/top and out on the right/bottom and pumps are always drawn with the flow from left to right.

Personally if this was your first big rig build I would build the system and run it with flexible connections (hoses) and slowly replace them with hard plumbing once I was certain exactly where and to what I wanted my connections.

its very important with hard plumbed system to make sure all the pipes and vessels self drain. otherwise you are creating traps for bacteria or left over cleaning chemicals. A grade of about 1 diameter/ 300 mm of run for 15mm pipes larger pipes can be a bit flatter (in the old money we would have said 1/2" 1D/foot 3/4"-1" about 1D/2 foot and 11/4"-2" 1 D/Yard)

The pumps need to be down low so they are self priming to avoid air bubbles and cavitation.

A bit more on pumps, well the valves near pumps, on the inlet side of the pump all valves should be full bore and only used in the fully open position, all control valves should be on the outlet side of the pump.

Plate and frame heat exchangers are the most commonly identified seat of infection in breweries. it is imperative that you be able to clean your HEx thoroughly, the best way is to be able to put some water/cleaner in the kettle and recirculate it through the HEx and back to the kettle, and that you recirculate boiling water through the loop for at least 10 minutes - you have plenty of time to do this while mashing - your circuit design as it stands doesn't allow this.

Have fun

Mark

B

bradsbrew

Guest

What did you decide for the mashtun 5150. What false bottom are you going to use?

Cheers

Cheers

davedoran

Well-Known Member

- Joined

- 19/4/10

- Messages

- 274

- Reaction score

- 31

5150 said:Thanks again Cocko, my understanding of whirlpool is pretty much exactly what you have state above. I will probably have a couple of different pipes to run down the side for wort transfer and whirlpooling depending on the size of the batch. I know you are right about the plumbing doing it once/right. Just counted out my taps and there will be 20, excessive I know, but it will allow me to do everything I want with having to move pipes/tubing around. like you said do it once. :icon_cheers: I'm still deciding between Camlock and Tri clover as in the end it's not going to be a major difference in cost?

Thanks Pratty for the tip, I'll give them a yell on Monday for a quote :icon_cheers:

If I have the pump there I may as well use it instead of using a paddle to whirlpool

Thanks lukiferj I'll post shots as soon as anything exciting stats to happen. At the moment I just have pics of a bedroom with three big ass pots and two hard core burners :super:

+1 for tri clover. Use them in work. Never had issues with them. Had a couple of problems with camlocks sealing.

Dunkelbrau

Well-Known Member

Nothing a hot caustic rinse wouldn't clean! How do you think the big boys do it ;-)Cocko said:I think it looks great, only thing I would think about is run of entering the bottom of the kettle rather than the top, avoiding splashing/HSA.

Other than that, looks great.

My preference is silicon, purely for ease of use and cleaning purposes - I would alway be wondering if a hard plumbed system is clean.

Keep us posted, looks like it is gonna be a killer rig!

Cheers

Edit: Beaten by Gava - Great minds....

Dunkelbrau

Well-Known Member

I can tell you now, tri clover fittings will piss you off during brew day I you have to untighten a lot of them and move them, cam locks will annoy you visually if you don't use them. Find the balance between utilizing both in the correct places and you will be happy!5150 said:Thanks again Cocko, my understanding of whirlpool is pretty much exactly what you have state above. I will probably have a couple of different pipes to run down the side for wort transfer and whirlpooling depending on the size of the batch. I know you are right about the plumbing doing it once/right. Just counted out my taps and there will be 20, excessive I know, but it will allow me to do everything I want with having to move pipes/tubing around. like you said do it once. :icon_cheers: I'm still deciding between Camlock and Tri clover as in the end it's not going to be a major difference in cost?

Thanks Pratty for the tip, I'll give them a yell on Monday for a quote :icon_cheers:

If I have the pump there I may as well use it instead of using a paddle to whirlpool

Thanks lukiferj I'll post shots as soon as anything exciting stats to happen. At the moment I just have pics of a bedroom with three big ass pots and two hard core burners :super:

5150

Well-Known Member

Thanks for all the suggestions guys.

BlueMutt, I'm only planning on doing one batch a day at this stage, so filtering the water for the plate chiller wouldn't be necessary as this water will only be used for cleaning at this stage, but you never know in the future and it would be a fairly easy mod.

MHB, Thanks for the feedback. This is my first big rig, so I'll definitely take on your advice and not hard plum at this stage. Very good point regarding cleaning of the HEX and it is something that I had overlooked, so I'll do some work on the my plumbing map to add this in. I've been working out all fittings and wow they are adding up having taps on every inlet/outlet of each pump and vessels. Thanks again.

Bradsbrew, I'm going to be using the same 150L pots for all three vessels. I know it's not the best and effective way of setting up the system, but I like the look of the the 3 same vessels and at the price they were almost the cheapest option. Regarding the false bottom, I did a fair bit of searching around on the net on Friday for different options and I think my plan is to try and get some perforated SS and maybe get it laser cut, this is all if I can find reasonable costs. If anyone has any suggestions or places taht they can recommend I'm all ears. :lol:

Grainer, I am going with the an electric HERM-IT with an STC or maybe PID. I have a bit of an issue with amount of amps in my garage, but I'm sure more automation will come with more power in the future. B)

Thanks Dave and Jurt, I'll be doing a little more research, thinking and costing today in regrds to fittings. :unsure:

Thanks again guys, I greatly appreciate all the advice becasue at the end of the day I'm still fairly new to all of this.

Cheers,

Richard

BlueMutt, I'm only planning on doing one batch a day at this stage, so filtering the water for the plate chiller wouldn't be necessary as this water will only be used for cleaning at this stage, but you never know in the future and it would be a fairly easy mod.

MHB, Thanks for the feedback. This is my first big rig, so I'll definitely take on your advice and not hard plum at this stage. Very good point regarding cleaning of the HEX and it is something that I had overlooked, so I'll do some work on the my plumbing map to add this in. I've been working out all fittings and wow they are adding up having taps on every inlet/outlet of each pump and vessels. Thanks again.

Bradsbrew, I'm going to be using the same 150L pots for all three vessels. I know it's not the best and effective way of setting up the system, but I like the look of the the 3 same vessels and at the price they were almost the cheapest option. Regarding the false bottom, I did a fair bit of searching around on the net on Friday for different options and I think my plan is to try and get some perforated SS and maybe get it laser cut, this is all if I can find reasonable costs. If anyone has any suggestions or places taht they can recommend I'm all ears. :lol:

Grainer, I am going with the an electric HERM-IT with an STC or maybe PID. I have a bit of an issue with amount of amps in my garage, but I'm sure more automation will come with more power in the future. B)

Thanks Dave and Jurt, I'll be doing a little more research, thinking and costing today in regrds to fittings. :unsure:

Thanks again guys, I greatly appreciate all the advice becasue at the end of the day I'm still fairly new to all of this.

Cheers,

Richard

5150

Well-Known Member

Gentlemen,

Finally an update. I have a ridiculous amount of stainless fittings in my lounge room. 150L stainless pots are all drilled and I'll hopefully get all the tri-clover fitting welded this week. I've got all the EPS panels and compressor/motor for building the fermentation chamber.

Anyway, I've finally managed to get some welding done on the rig and I've learnt some valuable lessons that I figured I should share.

1. gasless MIG welders are terrible.

2. TIG welders are way better

3. Sunburn or flashburn from welding is painful.

4. Welding is way easier after 2 beers, (steady hand)

5. Paint makes your welds look way way better.

Hopefully lots more updates over the next couple of weeks.

Cheers.

Finally an update. I have a ridiculous amount of stainless fittings in my lounge room. 150L stainless pots are all drilled and I'll hopefully get all the tri-clover fitting welded this week. I've got all the EPS panels and compressor/motor for building the fermentation chamber.

Anyway, I've finally managed to get some welding done on the rig and I've learnt some valuable lessons that I figured I should share.

1. gasless MIG welders are terrible.

2. TIG welders are way better

3. Sunburn or flashburn from welding is painful.

4. Welding is way easier after 2 beers, (steady hand)

5. Paint makes your welds look way way better.

Hopefully lots more updates over the next couple of weeks.

Cheers.

bazfletch3

Well-Known Member

- Joined

- 18/8/09

- Messages

- 120

- Reaction score

- 39

Love your work mate!

In my experience, there's a weird part of our brain that convinces us that regardless of the fact it may be 1, 2 or 20 years since we last welded, and in my case, that last time I was crap- THIS time, I'll be better.....

Cheers

Baz

In my experience, there's a weird part of our brain that convinces us that regardless of the fact it may be 1, 2 or 20 years since we last welded, and in my case, that last time I was crap- THIS time, I'll be better.....

Cheers

Baz

gava

I do rather like beer.....

- Joined

- 23/1/09

- Messages

- 1,198

- Reaction score

- 99

The pivot point on your tippy dump could be an issue.. If you have a large pot on this and you try and tip over since its on the very bottom its going to all the sudden fall back or forward once your holding pins are pulled.

I could be wrong but i think you'll need to bring your pivot point to the center of your pot, a good example is the morebeer tippy dump brewery (see picture below)

if you don't do this I predict some major spillage, plus if your holding pins snap under load all your mash would just fall out, if you have a center pivot its held in place.

my 2c anyway.

I could be wrong but i think you'll need to bring your pivot point to the center of your pot, a good example is the morebeer tippy dump brewery (see picture below)

if you don't do this I predict some major spillage, plus if your holding pins snap under load all your mash would just fall out, if you have a center pivot its held in place.

my 2c anyway.

Crouch

Well-Known Member

- Joined

- 4/10/13

- Messages

- 275

- Reaction score

- 63

Looks to be an interesting build.

Where did you source your 150l pots from?

Given the effort behind this project I'm sure you could have a higher amperage line ran into your garage - that is unless you are renting?

Looking forward to watching the progress.

Cheers

Where did you source your 150l pots from?

Given the effort behind this project I'm sure you could have a higher amperage line ran into your garage - that is unless you are renting?

Looking forward to watching the progress.

Cheers

5150

Well-Known Member

Gava, Thanks for the feedback and wow, you have an amazing looking setup, very jealous!!! ( I had a look at your site), maybe one day.  The mash tun will be secured to the frame with stainless wire and then a pin to hold it at a horizontal to scrape the grains out. (I might be missing something, if I am, please shout out).

The mash tun will be secured to the frame with stainless wire and then a pin to hold it at a horizontal to scrape the grains out. (I might be missing something, if I am, please shout out).

If any fellow brewer can think of a good use for 1.2mm stainless wire let me know and I'll send you as much as you like for the cost of postage. I found a reel on the road and I handed the reel in to the police station, after three months they gave it back. I have approx 5000 metres. (tied to ad a pic, too hard after too many beers, but the offer is genuine).

Crouch, I found the pot here http://aussiehomebrewer.com/topic/77835-150-liter-stainless-stock-pots/ I bought 3 three in the end got four. The pic of the brew rig is in my brothers garage where I did the welding, (he's doing better than me), I have rented a a small garage which is 2.4m x 5.2m. to brew me beers. I would add much more power is it was mine.

If any fellow brewer can think of a good use for 1.2mm stainless wire let me know and I'll send you as much as you like for the cost of postage. I found a reel on the road and I handed the reel in to the police station, after three months they gave it back. I have approx 5000 metres. (tied to ad a pic, too hard after too many beers, but the offer is genuine).

Crouch, I found the pot here http://aussiehomebrewer.com/topic/77835-150-liter-stainless-stock-pots/ I bought 3 three in the end got four. The pic of the brew rig is in my brothers garage where I did the welding, (he's doing better than me), I have rented a a small garage which is 2.4m x 5.2m. to brew me beers. I would add much more power is it was mine.

MastersBrewery

Journeyman, the learning never stops

- Joined

- 7/6/11

- Messages

- 2,319

- Reaction score

- 683

Gava own up, and stop posting that ridiculously sexy **** (NOT!) Give the rest of us mere mortals something we can at least try and build?!? or a link to where we can buy one cheap!!gava said:The pivot point on your tippy dump could be an issue.. If you have a large pot on this and you try and tip over since its on the very bottom its going to all the sudden fall back or forward once your holding pins are pulled.

I could be wrong but i think you'll need to bring your pivot point to the center of your pot, a good example is the morebeer tippy dump brewery (see picture below)

if you don't do this I predict some major spillage, plus if your holding pins snap under load all your mash would just fall out, if you have a center pivot its held in place.

my 2c anyway.

ty

MB

ED too pissed can't type

gava

I do rather like beer.....

- Joined

- 23/1/09

- Messages

- 1,198

- Reaction score

- 99

I still think your middle tippy design is going to give you some grief, let me see if I'm understanding it correctly5150 said:Gava, Thanks for the feedback and wow, you have an amazing looking setup, very jealous!!! ( I had a look at your site), maybe one day.The mash tun will be secured to the frame with stainless wire and then a pin to hold it at a horizontal to scrape the grains out. (I might be missing something, if I am, please shout out).

If any fellow brewer can think of a good use for 1.2mm stainless wire let me know and I'll send you as much as you like for the cost of postage. I found a reel on the road and I handed the reel in to the police station, after three months they gave it back. I have approx 5000 metres. (tied to ad a pic, too hard after too many beers, but the offer is genuine).

Crouch, I found the pot here http://aussiehomebrewer.com/topic/77835-150-liter-stainless-stock-pots/ I bought 3 three in the end got four. The pic of the brew rig is in my brothers garage where I did the welding, (he's doing better than me), I have rented a a small garage which is 2.4m x 5.2m. to brew me beers. I would add much more power is it was mine.

The tippy part is held horizontal with a pin... ontop of that is a 150lt pot putting pressure on the pin. If this pin breaks, bends, pops out you get 150l of hot mash either forward OR backward depending on how the grains are leaning in your pot?

If your pin doesn't break/ben under 150kg + your going to just pull the pin out easily? if not you'll have to give it a good pull and you have to hold the pot at the same time? once the pin is out you have to hold the 150lt pot with wet grains in it and lower it down to where the pin hole is and slide the pin in again while holding the pot. and then clean.

not trying to kill your design but I've been down this road see: http://aussiehomebrewer.com/topic/49146-e-herms-power-requirements-question/page-2#entry721250 and I really do think if I understand your design correctly, you'll be fiddling and burning yourself on brew days..

I great thing about the tippy design with the middle pivot is that if your holding pin breaks your pot self centers and hangs, sure it might be a little hard to tip over, you could get around this by adding a longish handle to pull it over with.. Just thought I'd put my ideas across and try to stop a awesome brewery build turn tits up with one simple design flaw.

If i've totally missed the mark with your design I'm sorry and ignore above.

EDIT: The pivot may have to be just over the middle looking back at the post, so it hangs.. if its in the middle it could still topple over.

-Gav

5150

Well-Known Member

Gav you are 100% right and thanks for taking the time. I'll need to address this before I brew. I originally had it designed more along the lines of yours and then changed it at the end as I was trying to do all the work myself and didn't have the ability to make the ring, but I should be able to get a fabricator to make this up for me without too much difficulty.

Thanks again.

Thanks again.

gava

I do rather like beer.....

- Joined

- 23/1/09

- Messages

- 1,198

- Reaction score

- 99

Not a problem, was looking back at my post and i think you need the pivot just above the center so it hangs.. in the center will still allow for uncontrolled tipping..

Can't wait to see the end result, might be in line for my next brewery rack.

-Gav

Can't wait to see the end result, might be in line for my next brewery rack.

-Gav

TheWiggman

Haters' gonna hate

On that theme, you'll want to secure the pot to the tipping platform. Otherwise when it starts to tilt it's going to want to slide off.

Regarding discussion above an option might be to install some trampoline springs in a V shaped fashion under the platform. The more it tilts the more tension is taken by the springs. That, or put a stop so in can't tilt in one direction, and only install 2 or 3 springs on one side.

Those pins look to be what, 12mm bar? As longs as they're well secured to your tilting frame there's no way they're going to snap under 75kg load each. They'll be able to tolerate over 2t under pure shear each.

Regarding discussion above an option might be to install some trampoline springs in a V shaped fashion under the platform. The more it tilts the more tension is taken by the springs. That, or put a stop so in can't tilt in one direction, and only install 2 or 3 springs on one side.

Those pins look to be what, 12mm bar? As longs as they're well secured to your tilting frame there's no way they're going to snap under 75kg load each. They'll be able to tolerate over 2t under pure shear each.

Adr_0

Gear Bod

- Joined

- 4/4/13

- Messages

- 1,776

- Reaction score

- 684

Looks awesome. I would probably cut out the red line from Pump 1 to the MLT and go through the HX - just leave the power/heat off while you are going from your HLT.5150 said:Hi Guys,

I'm just in the process of building a new brew stand and rig and I was after everyone's feedback, good and bad.

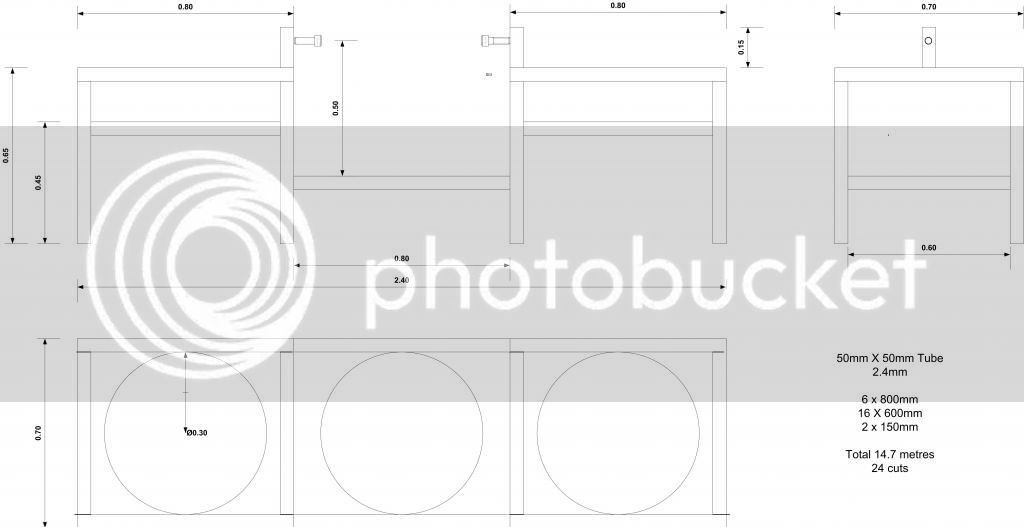

A bit of about what I am after is a stand to hold three 150 Liter stainless pots. The mash tun will be suspended half way up and 150mm to the front to allow me to tip the kettle over 90° to make it a little easier to clean and empty when I make big beers. It'll just be made from 50x50mm 2.4mm steel tube. I'm just going to go square cut as I can get the local shop to cut it for me as apposed to me having to buy a drop saw to cut all my 45°.

Anyway, I hope the image appears below as I just opened a photo bucket account just for this. :unsure:

As long as these images are appearing here is a pic of the plumbing I am thinking. Sorry the above image and this one is pretty basic. Everything is plumbed so that I don't have to move hoses etc while brewing. I feel like there is a ridiculous amount of hoses and plumbing, so please be as harsh as you like. Also wondering peoples opinion of plumbing with copper/Stainless as apposed to silicon??? I know it will have to do with cleaning.

Thanks in advance guys.

If my images didn't work here are the links to images.

I think you will be able to whirlpool fine with a paddle. If you want a pump, why not send it through the plate exchanger and back into the kettle, then drain from your kettle into the fermenter?

Definitely don't go into the bottom as you'll have a layer of cold wort in the bottom of your kettle. As Cocko suggested, go in 1/3 from the top of your wort and bent horizontal to give a whirlpool action. I don't know about different lengths for different batch sizes, but I would have a straight length to the bottom for filling the kettle, then swap it to your whirlpool arm.

My 6c...

5150

Well-Known Member

Gav, I've seen your gear, way better looking than this, but thanks. :beer: I was trying to figure out how to remedy the problem and I did really want to toss the center frame, ( too much work went into it), but I have now figured a new plan and I'm hopeing to maybe even get it welded in today, so I'll post an update.

Wiggman, the pot will be held down to stop it slipping, but the new plan will address all this. The pins are actually 20mm tube, but I'm going to put some bar through as a safety. It only spans a max of about 5mm, so not too worried.

The pins are actually 20mm tube, but I'm going to put some bar through as a safety. It only spans a max of about 5mm, so not too worried.

Adrian, funnily I have already cut out the red line going to the MLT when putting together my fittings. Thanks for the advice with the whirlpooling.

Thanks for the advice with the whirlpooling.

Kettles get welded Saturday morning, so it's all starting to come together. Thanks for all the comments. :beerbang:

Wiggman, the pot will be held down to stop it slipping, but the new plan will address all this.

Adrian, funnily I have already cut out the red line going to the MLT when putting together my fittings.

Kettles get welded Saturday morning, so it's all starting to come together. Thanks for all the comments. :beerbang:

Similar threads

- Replies

- 0

- Views

- 2K

- Replies

- 0

- Views

- 1K

- Replies

- 4

- Views

- 3K

- Replies

- 13

- Views

- 5K