Edak

BrauShnizzleMyNizzle

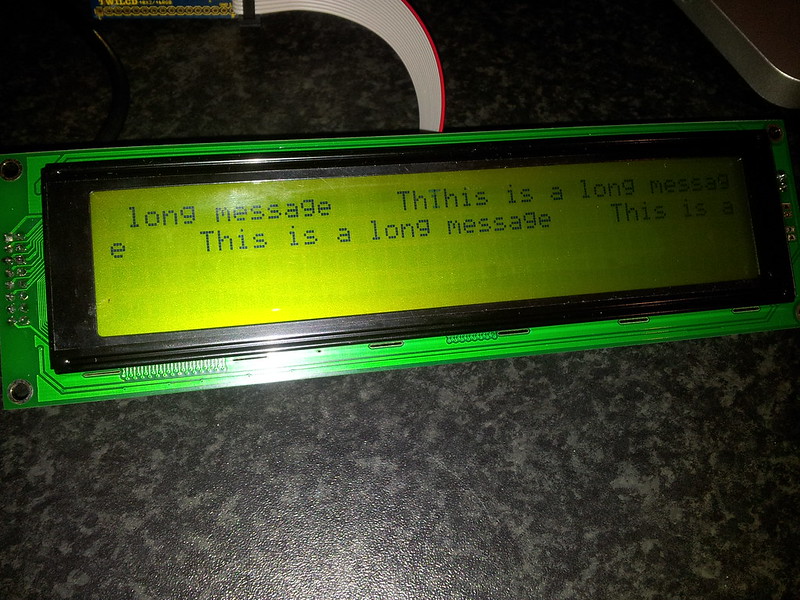

I know you just want to big-note yourself in this thread, and you're probably deliberately missing the point, but if you are using a 16x2 LCD to display text you are probably using strings.

Like this:

https://github.com/mathoaus/braumiser-contr...duino2.pde#L368

or this:

https://github.com/mathoaus/braumiser-contr...uduino2.pde#L86

The ezLCD is no different - if not, more efficient.

Anyway the arduino LCD lib adds ~2kB to the binary size. Which is a fair amount of strings for menus etc. for ezLCD before you get to the equivalent binary size.

And I think you ment storing not sending is inefficient. But as you already pointed out, it is well known and easy to fix.

Hey Zizzle I think you missed my point.

I totally agree that the LCD you were talking about is a good idea. You say to use only characters for the graphic LCD, which is great. If you use a 16x2 then you need to send strings. I was trying to further your point by saying that Strings are bad, admittedly I was not clear about this.

Your point about using 2k for the driver is a bit misleading though, because the graphic LCD uses the Serial library, which uses 1.3k of flash.

Thanks for flaming me though, much appreciated.

Vortex,

I2C displays are great! If you have any trouble getting it to work with the LiquidCrystal_I2C driver let me know because I personally had to make a change to it to get it to work for mine, possibly because I bought a cheap eBay display from China and their documentation was wrong. If you are using a regular 5V Arduino you will be alright, but if you have a 3.3V Arduino, like some of the Pro minis you will have problems with the I2C backpack because they expect different signal levels.