Alrighty. After a 6 month hiatus this project is almost finished!

Mistakes have been made and lessons learnt.

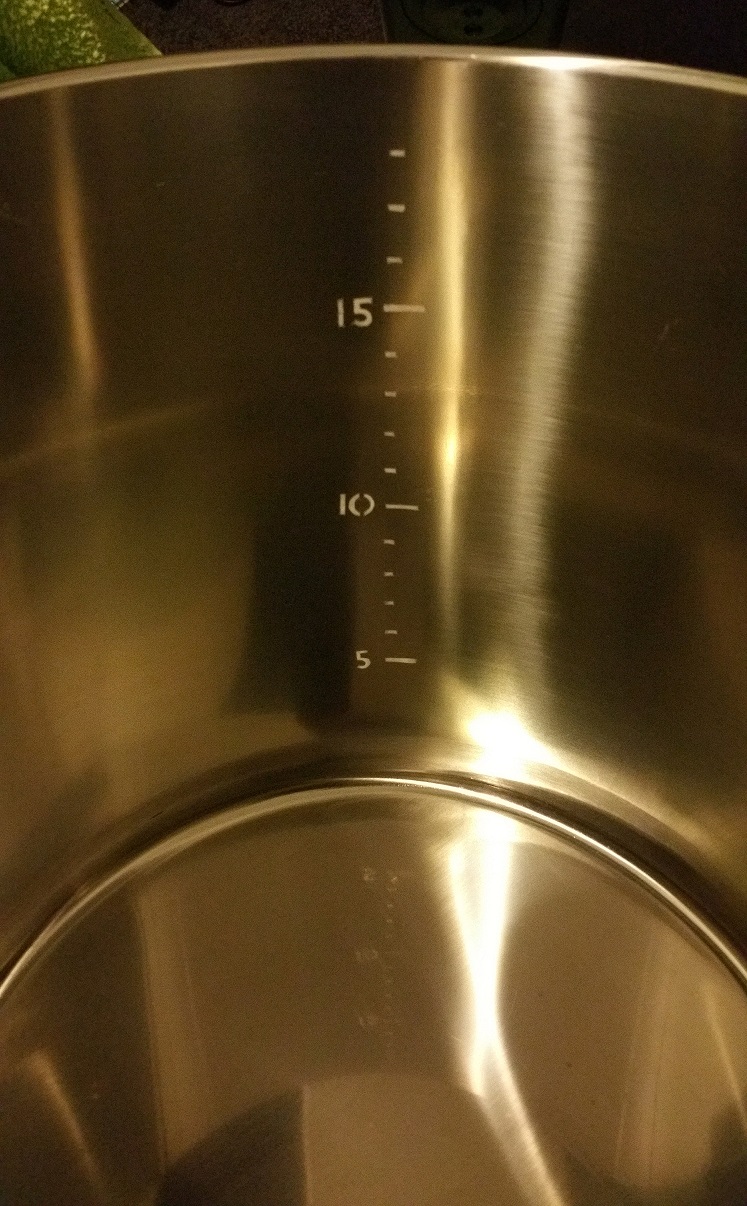

First of all, I learnt to not try to hand drill large (>1") holes in stainless steel. I was impatient and found a perfectly sized hole saw and arbor rather than buy and wait for a hole punch. So the 32mm hole needed to pass the heating element through was.. imperfect. This lead to issues with getting it water tight so I eventually got a plumber friend to weld on a 1"socket to the pot. Problem solved! (the warping of the pot is due to the weld pulling on the metal as it cools and it's a very thin pot)

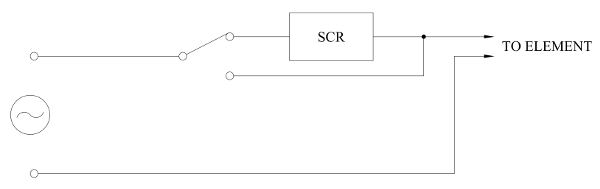

The wiring of the control box was daunting and it took me ages to get around to actually doing it. but in the end it turned out really great (first test run was last night)

Progress pics of control box -

http://imgur.com/a/7oVhK

I stupidly haven't taken wide angle shots to show the whole thing, but you can see in some of the pics that I made a little wooden table from cheap wood to give clearance to the tap underneath and have somewhere to mount the pump.

Other than that, all the fittings are watertight and work well. The quick disconnect fittings on the lid got unbearably hot when I was testing the time it took to get the system up to boiling. But at mash temperatures it was easy to disconnect with bare hands and i'm really happy with such a compact solution.

'm also really happy with the spiral nozzle in the lid. It has a good flow rate, is highly unlikely to get clogged. I've yet to test if it's enough of a spread to reduce channeling.

I'll post some wide pictures when i get home to show the whole setup together.