droid

somewhere on the slippery slope with a beer in han

I have just lost a heap of text for this thread from my pc crashing and the wind has been taken out of my sails a little.

Fascinated by plumbing and valving of different brew systems I thought it would be nice to start a dedicated conversation about the plumbing aspect. Please merge if there is a thread, I couldn't find it and I think it deserves to stand alone from the show us your brew-rig thread or at least not muddy those waters...

This is a pic of my 4 vessel brew-house as it stands. I'll explain what's plumbed where and why and would love to hear about what I could do better. I'd also love to see what other people are doing and why they are doing it.

Here's cheers to brew-plumbing :beer:

This system works right to left so it's a bit different in that regard. Sorry, also everything is written as-you-look at it...Right is the HLT, next is the heat exchange and recirculation, next is the mash-tun and on the left is the kettle

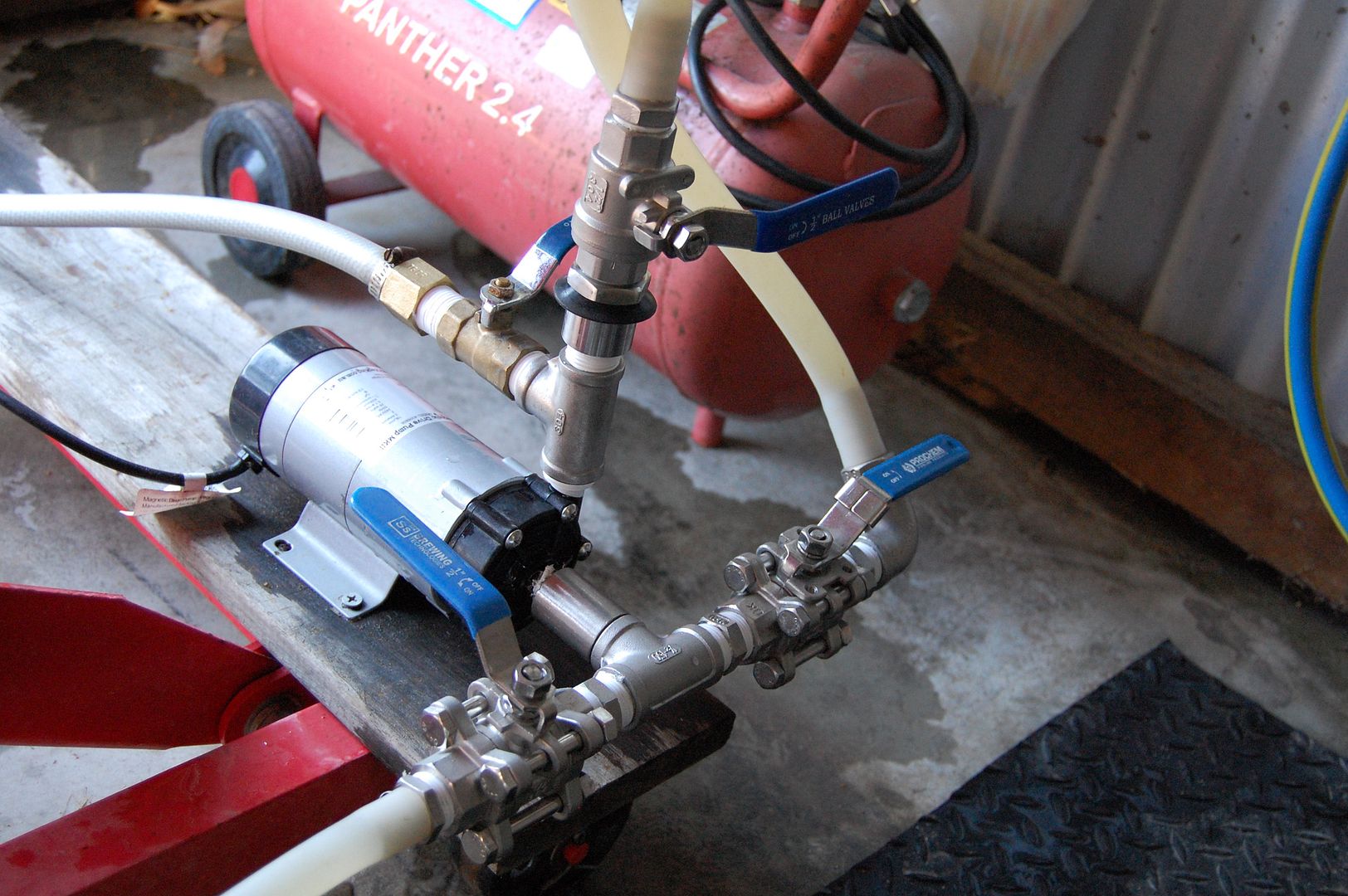

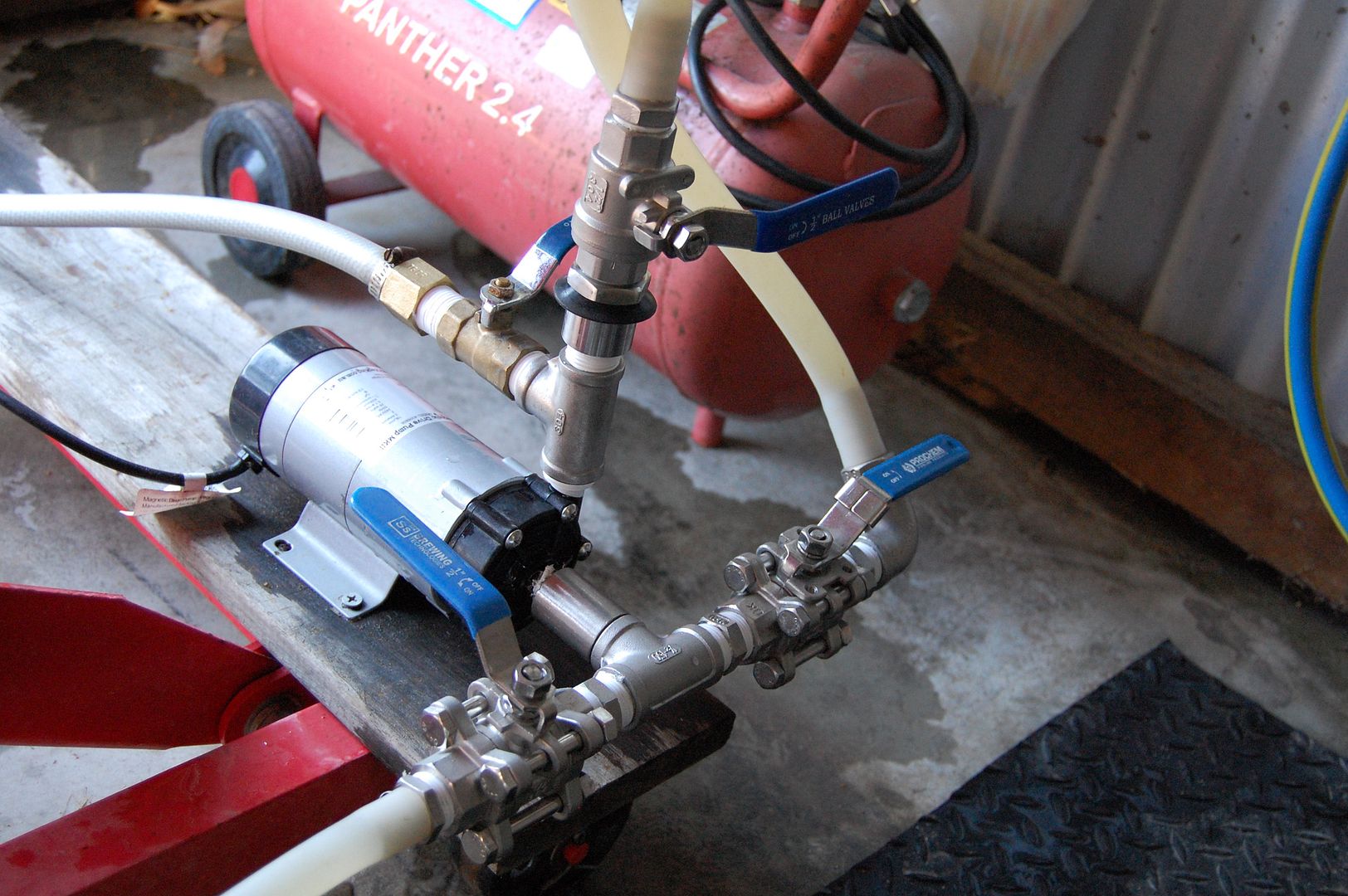

This is the plumbing under the HLT. The hose running into the pump (from the right) is the only hose on the HLT (it will have recirc and probably house the HERMS eventually)

Hot Water coming in, that hot water can go straight through the pump and into the recirculation for the heat exchange or HERMS which is the tube coming out the top of the pump and going straight up.

The other valve located behind the pump out is to drain the system and can be used to fill with food grade hose if required

The valve on the left is there to accept the runnings from the mash and send it through the pump back into the HERMS. It also allows liquid from the kettle and chiller side to pass through.

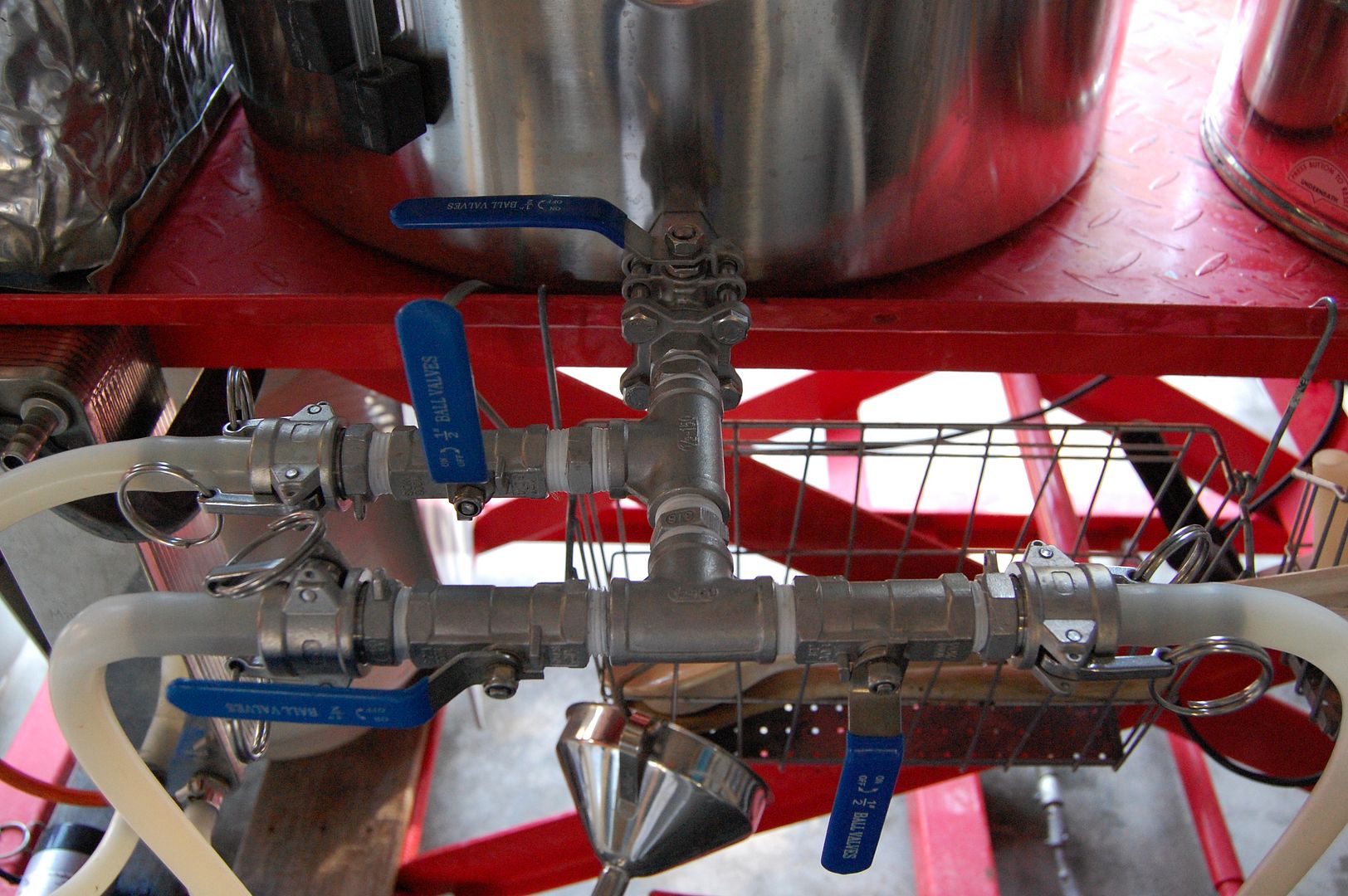

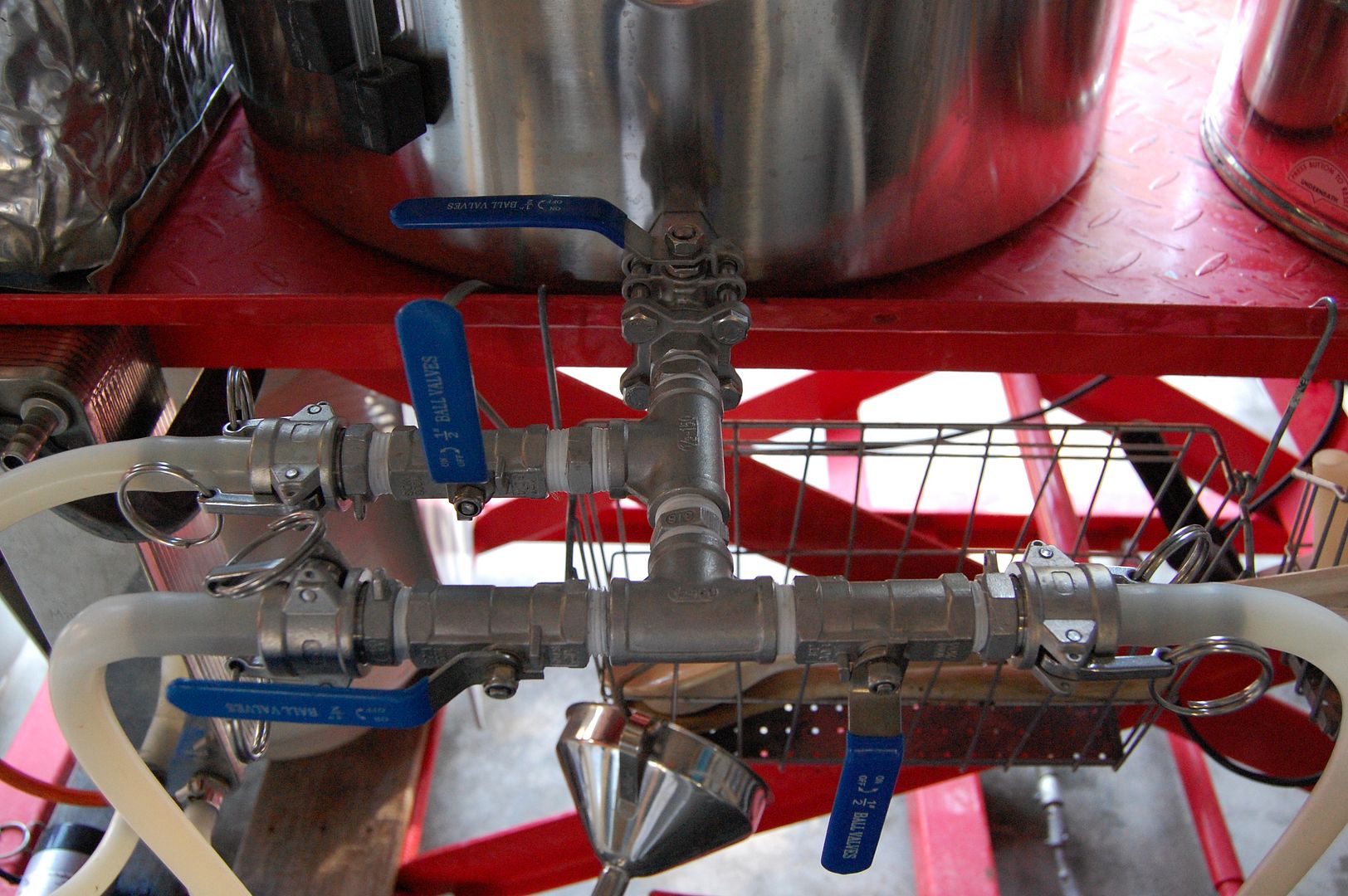

This is the plumbing on the mash-tun.

Main valve to and from mash-tun

The valve in the middle on the left is from the plate chiller and it's only use is to bring the water out from the plate chiller. It can be diverted to the mash-tun if I've cleaned it in time and can also go to the HLT via the valve on the right which travels down to the pump under the HLT.

The left front valve allows the clear wort from the mash to go to the kettle but also allows hot water or cleaning solution from the HLT. So basically the two front valves, left and right allow transfer from left to right or vice versa.

It has release clamps so that the mash-tun can be removed to get the grain out. I will maybe build a swing for the mash-tun for easy tipping, maybe not.

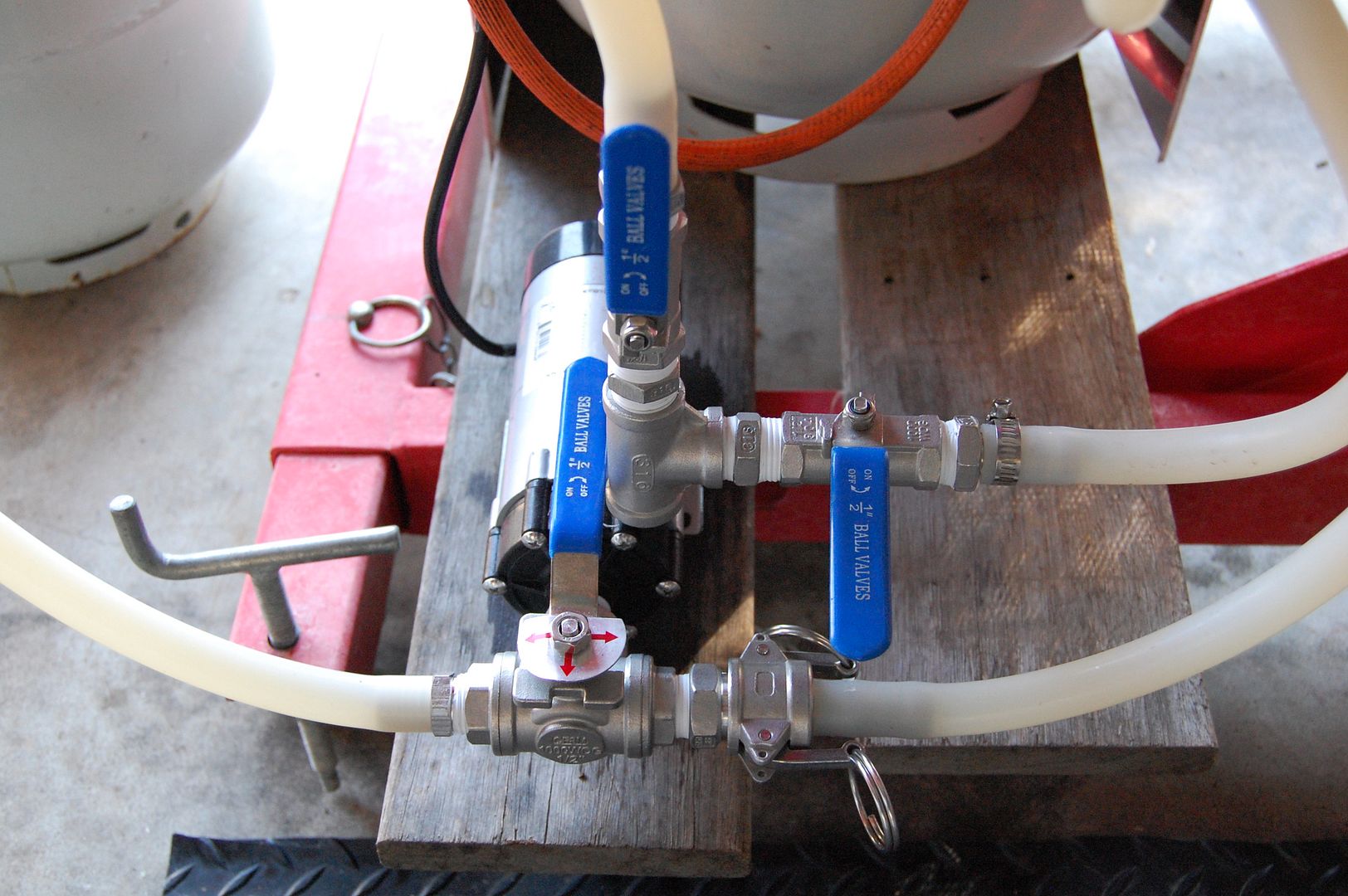

Here is the valving under the kettle.

The hose on the right is to allow liquid in from the mash or from the HLT and obviously it can release liquid back to the right, depending, this pump has a 3 way valve controlling liquid in to the pump but the great thing about it is you can swing it around and open up the left and right hoses bypassing the pump if needed

The hose on the left is liquid out from kettle but as mentioned it also diverts flow back into the pump from the kettle, mash-tun or HLT

The valve on top of the pump (pump out) is fed into the kettle (two valves on the kettle) and is used for filling but also for recirculating and creating a whirlpool

The valve off to the right is for feeding into the chiller

The kettle valves.

Top is liquid in so I can fill the kettle with wort, recirculate but also for cleaning.

Bottom is liquid out but can be used for liquid in from HLT.

Once I connect the hose to the chiller (water in) I can feed the whole system and with the hose out on the HLT side I can water the garden and drain the sytem without going anywhere. The missing hose out from the chiller is a slip on tee piece for filling two FV's at once if required. The reason for the tee is that I don't like to stop the chilling to swap over to another FV if I do a bigger brew.

Whaddya think?

I'd like to increase my whirlpool speed and was wondering if I can do that through altering hose length? or valve size? Those smaller valves are 1/2"bsp but the internal size looks like 8-10mm.

What have you got...and why?

Fascinated by plumbing and valving of different brew systems I thought it would be nice to start a dedicated conversation about the plumbing aspect. Please merge if there is a thread, I couldn't find it and I think it deserves to stand alone from the show us your brew-rig thread or at least not muddy those waters...

This is a pic of my 4 vessel brew-house as it stands. I'll explain what's plumbed where and why and would love to hear about what I could do better. I'd also love to see what other people are doing and why they are doing it.

Here's cheers to brew-plumbing :beer:

This system works right to left so it's a bit different in that regard. Sorry, also everything is written as-you-look at it...Right is the HLT, next is the heat exchange and recirculation, next is the mash-tun and on the left is the kettle

This is the plumbing under the HLT. The hose running into the pump (from the right) is the only hose on the HLT (it will have recirc and probably house the HERMS eventually)

Hot Water coming in, that hot water can go straight through the pump and into the recirculation for the heat exchange or HERMS which is the tube coming out the top of the pump and going straight up.

The other valve located behind the pump out is to drain the system and can be used to fill with food grade hose if required

The valve on the left is there to accept the runnings from the mash and send it through the pump back into the HERMS. It also allows liquid from the kettle and chiller side to pass through.

This is the plumbing on the mash-tun.

Main valve to and from mash-tun

The valve in the middle on the left is from the plate chiller and it's only use is to bring the water out from the plate chiller. It can be diverted to the mash-tun if I've cleaned it in time and can also go to the HLT via the valve on the right which travels down to the pump under the HLT.

The left front valve allows the clear wort from the mash to go to the kettle but also allows hot water or cleaning solution from the HLT. So basically the two front valves, left and right allow transfer from left to right or vice versa.

It has release clamps so that the mash-tun can be removed to get the grain out. I will maybe build a swing for the mash-tun for easy tipping, maybe not.

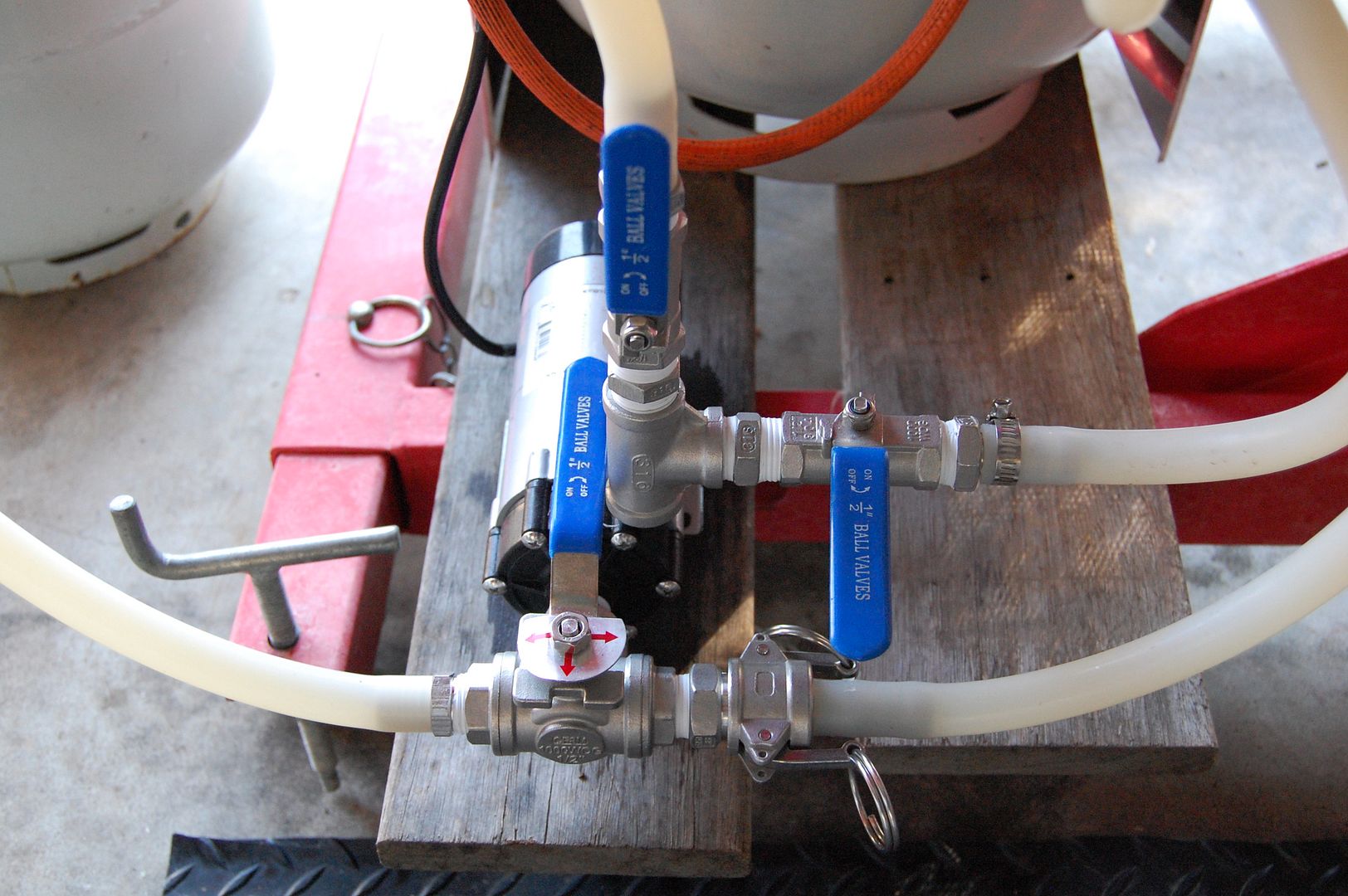

Here is the valving under the kettle.

The hose on the right is to allow liquid in from the mash or from the HLT and obviously it can release liquid back to the right, depending, this pump has a 3 way valve controlling liquid in to the pump but the great thing about it is you can swing it around and open up the left and right hoses bypassing the pump if needed

The hose on the left is liquid out from kettle but as mentioned it also diverts flow back into the pump from the kettle, mash-tun or HLT

The valve on top of the pump (pump out) is fed into the kettle (two valves on the kettle) and is used for filling but also for recirculating and creating a whirlpool

The valve off to the right is for feeding into the chiller

The kettle valves.

Top is liquid in so I can fill the kettle with wort, recirculate but also for cleaning.

Bottom is liquid out but can be used for liquid in from HLT.

Once I connect the hose to the chiller (water in) I can feed the whole system and with the hose out on the HLT side I can water the garden and drain the sytem without going anywhere. The missing hose out from the chiller is a slip on tee piece for filling two FV's at once if required. The reason for the tee is that I don't like to stop the chilling to swap over to another FV if I do a bigger brew.

Whaddya think?

I'd like to increase my whirlpool speed and was wondering if I can do that through altering hose length? or valve size? Those smaller valves are 1/2"bsp but the internal size looks like 8-10mm.

What have you got...and why?