Zizzle

Well-Known Member

- Joined

- 22/4/06

- Messages

- 1,001

- Reaction score

- 5

I suspect there are some techies/engineers here that would get something out of this post. Pat actually asked me to do this in laymans terms, but that is harder, and may come later.

I got the temp control unit from brissybrew which is great, but at about the time I set it up, ambient temps were swinging below 12 over night and over 25 during the day. I didn't really have an idea of how warm/cool it was getting downstairs. I figured I would really needed to cool and heat, but the simple little controller will only do one at a time.

I've got a Systems Engineering degree so I figured I could probably sort something out. So after scouting arount, I worked out I could get a digital multimeter with RS-232 output for about $50. Not bad, but that would be only one sensor. Low speed data aq gear can be had for $25 to hook up to a PC. But I would need to buy and wire thermocouples.

Then I found the DS1820. It can be wired up to a PC pretty easily. 1-wire bus with parasitic power it very cool. Linux drivers. I was set.

http://www.linuxfocus.org/English/November...rticle315.shtml

Now price in aus: $20 each. WTF? Go to the dallas semi website and they are listed at US$3. That is quite a markup for something the size of a transistor. But wait, they send out FREE samples. Great.

So the plan is, put some sensors in the fridge, wire up some relays to switch the fridge and a globe inside, write some software to controll it from a PC. Easy.

Then I discover the old laptop I have been saving for just such an occasion has a dead hard disk.

Plan B: run enough cable up stairs to a PC there. Also to make cabling easier by using CAT5, and so RJ45 sockets at each end.

Wire the circuit to drive the DS1820 into the serial port plug.

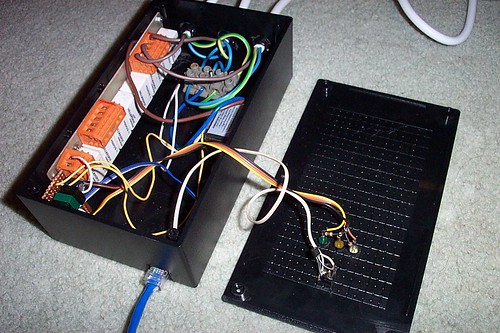

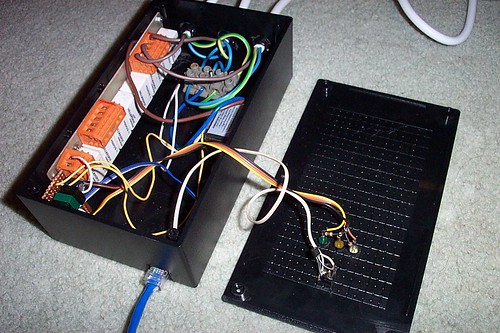

Next snag, I need to drive 2 relays, but there is only one output left on the DB-9 RS-232 port. Need to get some more outputs from the parallel port. Oh well not as neat but will do the job:

I find an 8-way relay board in my junk boxes. Should do the job. The relays are rated 5A. I will wire 2 pairs up in parallel just to be sure.

Relay coils need a fair bit of juice. Not really, but more than I want to draw from the poor old PC parallel printer port. The box will have mains in it, so simple to add a small transformer. Jaycar $7. Jam some leds on the front for power, heat, cool. Couple of 3.5mm audio jack for connecting the DS1820s to the bus. All in a jiffy box.

Bit of heat shrink tubing around the DS1820s:

Total spend: about $20. Plus a few hours stuffing around soldering and drilling holes in the case.

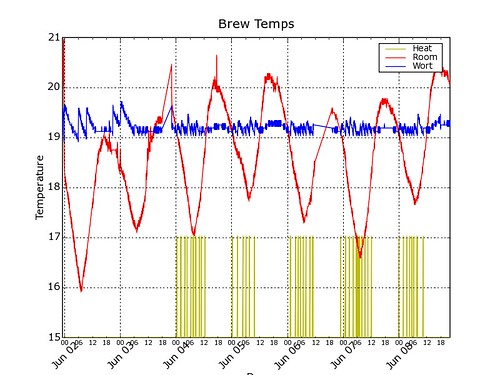

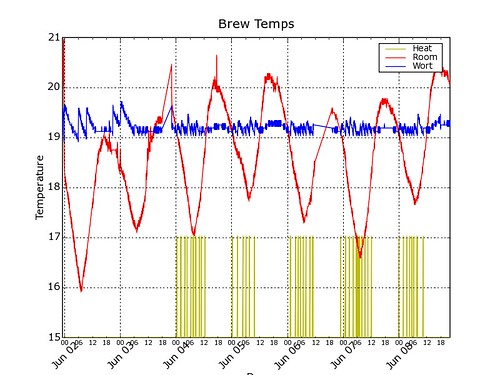

Results:

So it turns out that after all that, that the temps inside are actually quite stable, and around the right value.

Oh well it was fun anyway.

I got the temp control unit from brissybrew which is great, but at about the time I set it up, ambient temps were swinging below 12 over night and over 25 during the day. I didn't really have an idea of how warm/cool it was getting downstairs. I figured I would really needed to cool and heat, but the simple little controller will only do one at a time.

I've got a Systems Engineering degree so I figured I could probably sort something out. So after scouting arount, I worked out I could get a digital multimeter with RS-232 output for about $50. Not bad, but that would be only one sensor. Low speed data aq gear can be had for $25 to hook up to a PC. But I would need to buy and wire thermocouples.

Then I found the DS1820. It can be wired up to a PC pretty easily. 1-wire bus with parasitic power it very cool. Linux drivers. I was set.

http://www.linuxfocus.org/English/November...rticle315.shtml

Now price in aus: $20 each. WTF? Go to the dallas semi website and they are listed at US$3. That is quite a markup for something the size of a transistor. But wait, they send out FREE samples. Great.

So the plan is, put some sensors in the fridge, wire up some relays to switch the fridge and a globe inside, write some software to controll it from a PC. Easy.

Then I discover the old laptop I have been saving for just such an occasion has a dead hard disk.

Plan B: run enough cable up stairs to a PC there. Also to make cabling easier by using CAT5, and so RJ45 sockets at each end.

Wire the circuit to drive the DS1820 into the serial port plug.

Next snag, I need to drive 2 relays, but there is only one output left on the DB-9 RS-232 port. Need to get some more outputs from the parallel port. Oh well not as neat but will do the job:

I find an 8-way relay board in my junk boxes. Should do the job. The relays are rated 5A. I will wire 2 pairs up in parallel just to be sure.

Relay coils need a fair bit of juice. Not really, but more than I want to draw from the poor old PC parallel printer port. The box will have mains in it, so simple to add a small transformer. Jaycar $7. Jam some leds on the front for power, heat, cool. Couple of 3.5mm audio jack for connecting the DS1820s to the bus. All in a jiffy box.

Bit of heat shrink tubing around the DS1820s:

Total spend: about $20. Plus a few hours stuffing around soldering and drilling holes in the case.

Results:

So it turns out that after all that, that the temps inside are actually quite stable, and around the right value.

Oh well it was fun anyway.