1) With your upcoming Series X Plus, will you be having two single fonts or a modular font?

The Series X Plus will have two pre-drilled holes on top so you will be able to fit two of these fonts below that are the cheapest option:

Single Font

Double Font

Triple Font

Quad Font

With that said some people may want to use the

modular fonts and these are compatible too. The modular fonts are more expensive but some customers like the industrial look of them.

We are working on a number new font designs too that are made from punched steel and in terms of price will be less expensive than the current modular ones but slightly more expensive than the first option mentioned above. They will use a whole new font assembly method that will also make it a bit easier to access the back of the shanks too.

2) Update with your product that allows dry hopping through a carb cap/tee piece please?

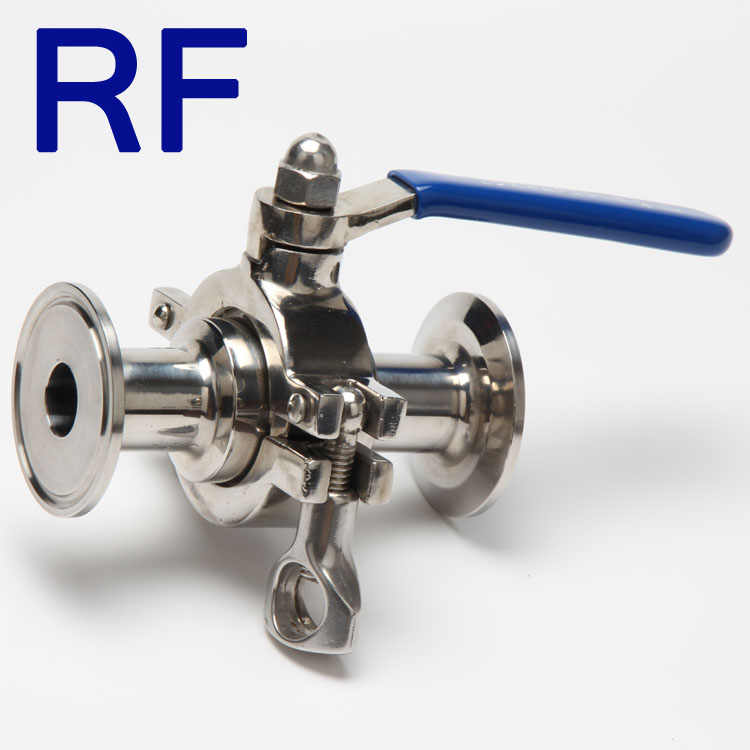

We do have this valve already made. We have a stainless steel ball valve that we are testing at the moment that has two PCO1881 female threads on both sides. This will enable you to put hops into a PET coke bottle, fill the bottle with hops, then open the ball valve to dump them into the lid of a FermZilla. I think this will be available in 1 month or so.

PCO1881 x PCO1881 Female Ball Balve - Dry Hop Device for FermZilla

3) Update with your inline digital gauge please?

We have finished the design process and the product is now moved to manufacturing. We are waiting for the injection moulds to get finished. It's likely that these are going to be quite popular as we have already had quite a few people requesting this. I think it hopefully will be available by the end of the year but hard to say exactly. We have been doing a lot of work with digital pressure transducers at the moment and we have some other really cool products that use them too that will be available soon.

4) Do you anticipate that your new flow control disconnects will make beer line length obsolete?

I think we will always get people who prefer the simplicity of just using a small ID Beer Line rather than another device. With that said the new FC design will be at a lower price point and accessible to everyone. We are trying to also re-design the poppet mechanism at the same time. Just out of interest do any of you guys ever have the issue of blowing the o-ring out of your poppet when using high gas pressures? We are considering a new better single piece poppet design for both disconnects and ball lock posts.