reVoxAHB

Well-Known Member

- Joined

- 3/3/07

- Messages

- 1,112

- Reaction score

- 17

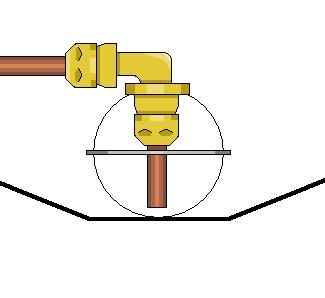

reVox... My guess is that a lot of the fines and flour can migrate through and under the false bottom as you mash in. Would have basically put a layer of mud around that secondary teaball screen you inserted underneath.

I've found with S/S false bottoms that you'll always need some degree of recirculation to set up the grain bed. When I used the 12 inch in my mash tun it took around 8-10 litres to achieve clarity. With the 9 inch I only need around half the amount.

Yep, you're spot on Warren.

We brew and learn :excl:

Sure hope it wasn't the crush... The Craphaus gives no money back guarantees. :lol:

Warren -

Hehe! You mean the Craphaus crush that gave me a 5% gain in efficiency?

I'll gladly take that, anyday.. no refund required

Cheers,

reVox