You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fully Automated Brewing System Design

- Thread starter Bandito

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Bandito

Well-Known Member

- Joined

- 23/1/09

- Messages

- 528

- Reaction score

- 1

Was planning on subbing it out - open to members making it to my designs too! If anyone that can weld stainless and wants a job? Considering getting a welder myself too, and jumping in the deep end, not sure yet. Pm me if interested in quoting to make 2 like shown on previous page plus one conical fermenter, or part thereof.

A major issue has surfaced this week - the aussie dollar is diving hardcore! I was expecting this at sometime, and thats why I did the big international purchases early - to take advantage of the high dollar. I have purchased two automated tablet dispensers for the hop dispenser part, but am delaying the relay board purchase until I have read through the labview site a bit more to be sure I get the right parts.

Given the dollar, I might have to put the international purchases on hold and focus on the local stainless vessels instead. I have only welded a few times, which is pretty sad for someone that drafts steel buildings! I should really man up and get myself a welding rig! I have ben looking on youtube for SS welding vids, anyone know of any good tutorials? Or care to post some?

The butterfly valves require a heavy (thick) flange which is available off the shelf and known as an ANSI 150 flange, this is because of the large distance between the contact part and the bolts. I am going to look into using standard reducers (which are conical) to adapt the 300mm valve to a larger size pf standard pipe, but I still have to look up the catalogues for those. A custom thin walled vessel welded to the starndard think flange would be the go I think. There will be plenty of gussets (stiffeners (triangular plates)) welded between the horizontal flange and the vertical wall of the vessel to distribute the stresses.

The Lights Out brewery will be Electric. Thats what I am thinking of calling it now. Motto will be along the lines of: I'm out fishing, but the automatron is still brewing! So harden the **** up!

A major issue has surfaced this week - the aussie dollar is diving hardcore! I was expecting this at sometime, and thats why I did the big international purchases early - to take advantage of the high dollar. I have purchased two automated tablet dispensers for the hop dispenser part, but am delaying the relay board purchase until I have read through the labview site a bit more to be sure I get the right parts.

Given the dollar, I might have to put the international purchases on hold and focus on the local stainless vessels instead. I have only welded a few times, which is pretty sad for someone that drafts steel buildings! I should really man up and get myself a welding rig! I have ben looking on youtube for SS welding vids, anyone know of any good tutorials? Or care to post some?

The butterfly valves require a heavy (thick) flange which is available off the shelf and known as an ANSI 150 flange, this is because of the large distance between the contact part and the bolts. I am going to look into using standard reducers (which are conical) to adapt the 300mm valve to a larger size pf standard pipe, but I still have to look up the catalogues for those. A custom thin walled vessel welded to the starndard think flange would be the go I think. There will be plenty of gussets (stiffeners (triangular plates)) welded between the horizontal flange and the vertical wall of the vessel to distribute the stresses.

The Lights Out brewery will be Electric. Thats what I am thinking of calling it now. Motto will be along the lines of: I'm out fishing, but the automatron is still brewing! So harden the **** up!

matho

The Braumiser

- Joined

- 30/4/08

- Messages

- 1,403

- Reaction score

- 142

bandito,

you might want to wait until you have a vessel made before you test the force required to open the butterfly valves the weight of the spent grain might change the force.

it might or it might not just a suggestion.

cheer's matho

you might want to wait until you have a vessel made before you test the force required to open the butterfly valves the weight of the spent grain might change the force.

it might or it might not just a suggestion.

cheer's matho

yardy

BI3V

- Joined

- 25/2/06

- Messages

- 3,065

- Reaction score

- 10

There will be plenty of gussets (stiffeners (triangular plates)) welded between the horizontal flange and the vertical wall of the vessel to distribute the stresses.

slip on or weld neck flange ?

bum

Not entitled to an opinion

- Joined

- 19/2/09

- Messages

- 11,585

- Reaction score

- 911

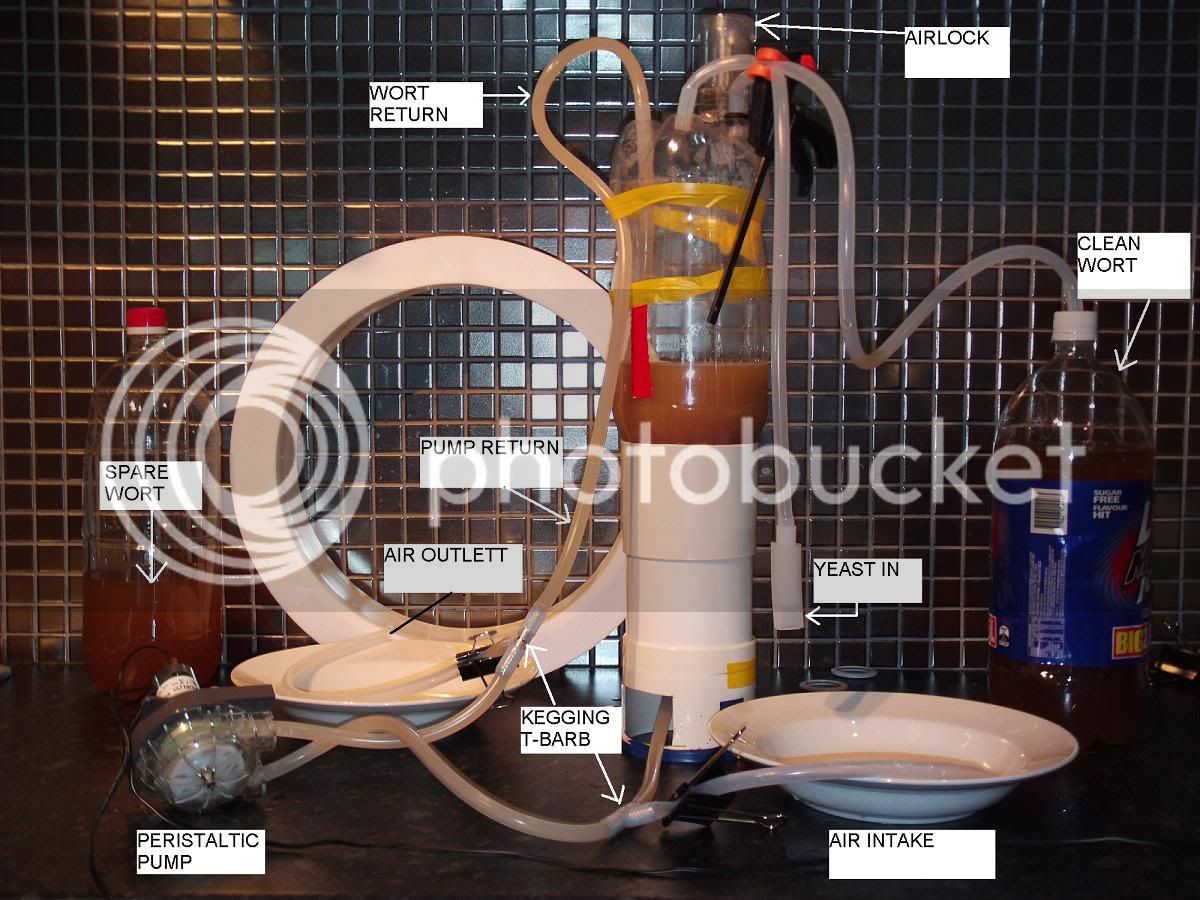

Inspired by Absinthe's malting thread, I have decided to add self malting and kilning to the fully automated brewery. Been thinking about it for about a month, and in the last few days have built up a reasonalbe 3d model in my head. Will model it in cad as time permits, and post when ready, but will basically be a perforated Stainless Steel drum that rotates inside a larger SS drum. Will have water sprayers for soaking, and a heating element for kilning. Will be insulated to allow use like an oven.

Can anyone else remember who it was that made the thread about his bastardised-clothes-dryer-as-grain-malter thread a while back? Might be insightful and, if suitable, easier to bolt on to the design than something made from scratch.

bum

Not entitled to an opinion

- Joined

- 19/2/09

- Messages

- 11,585

- Reaction score

- 911

Oh, found the thread I am thinking of and it turns out it was Absinthe after all (and not quite build pictures).

http://www.aussiehomebrewer.com/forum//ind...showtopic=35419

http://www.aussiehomebrewer.com/forum//ind...showtopic=35419

Bandito

Well-Known Member

- Joined

- 23/1/09

- Messages

- 528

- Reaction score

- 1

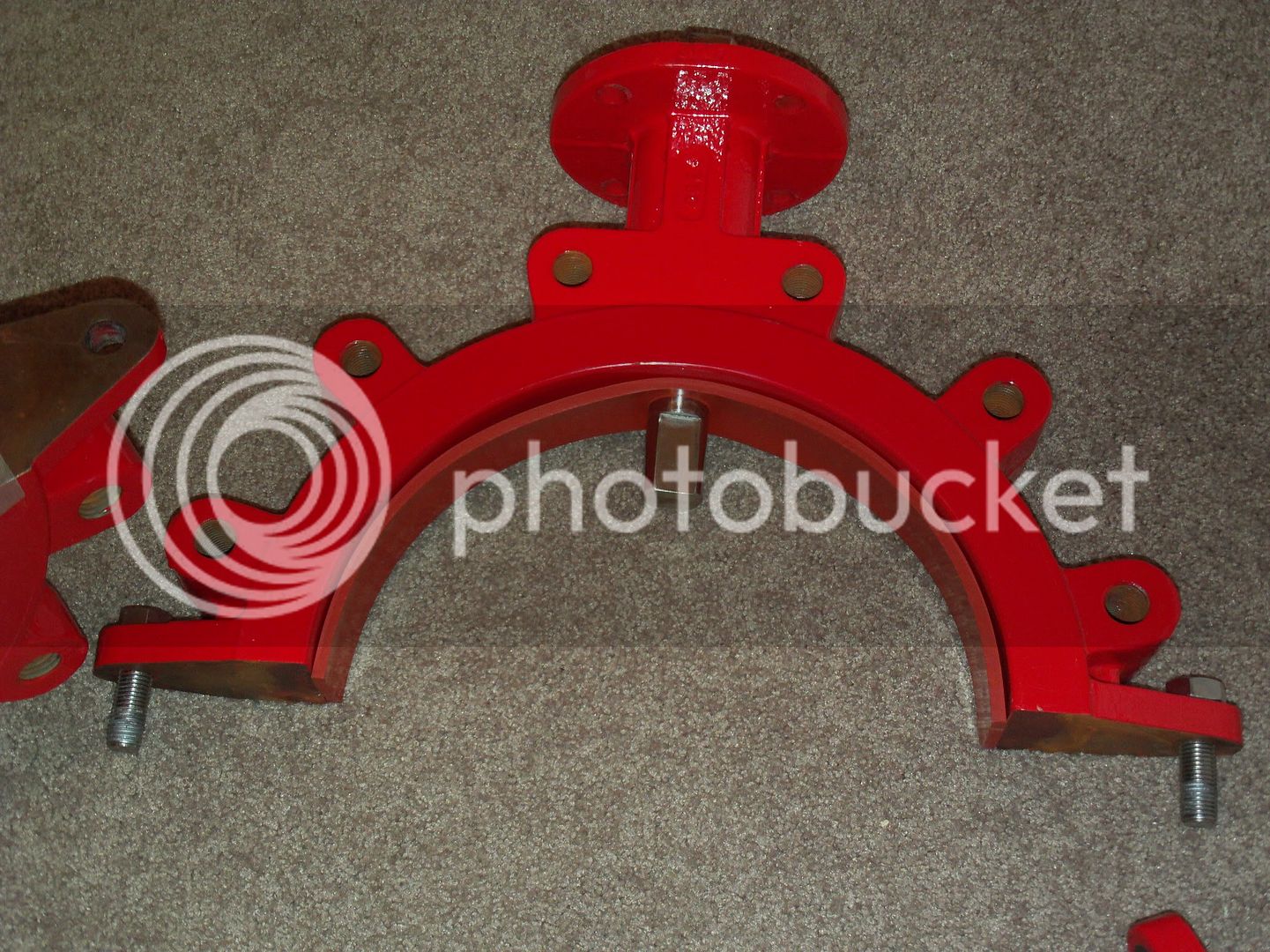

Last weekend I was sleeping in when I heard my downstairs neighbours discussing the possible contents of the mystery pallet of butterfly valves in the carport, so I jumped out of bed and stumbled out the door to make sure they werent stuffing with my precious!

Later that day I decided they only way to get them in the house was to take them apart and lift them in piece by piece.

Pics follow:

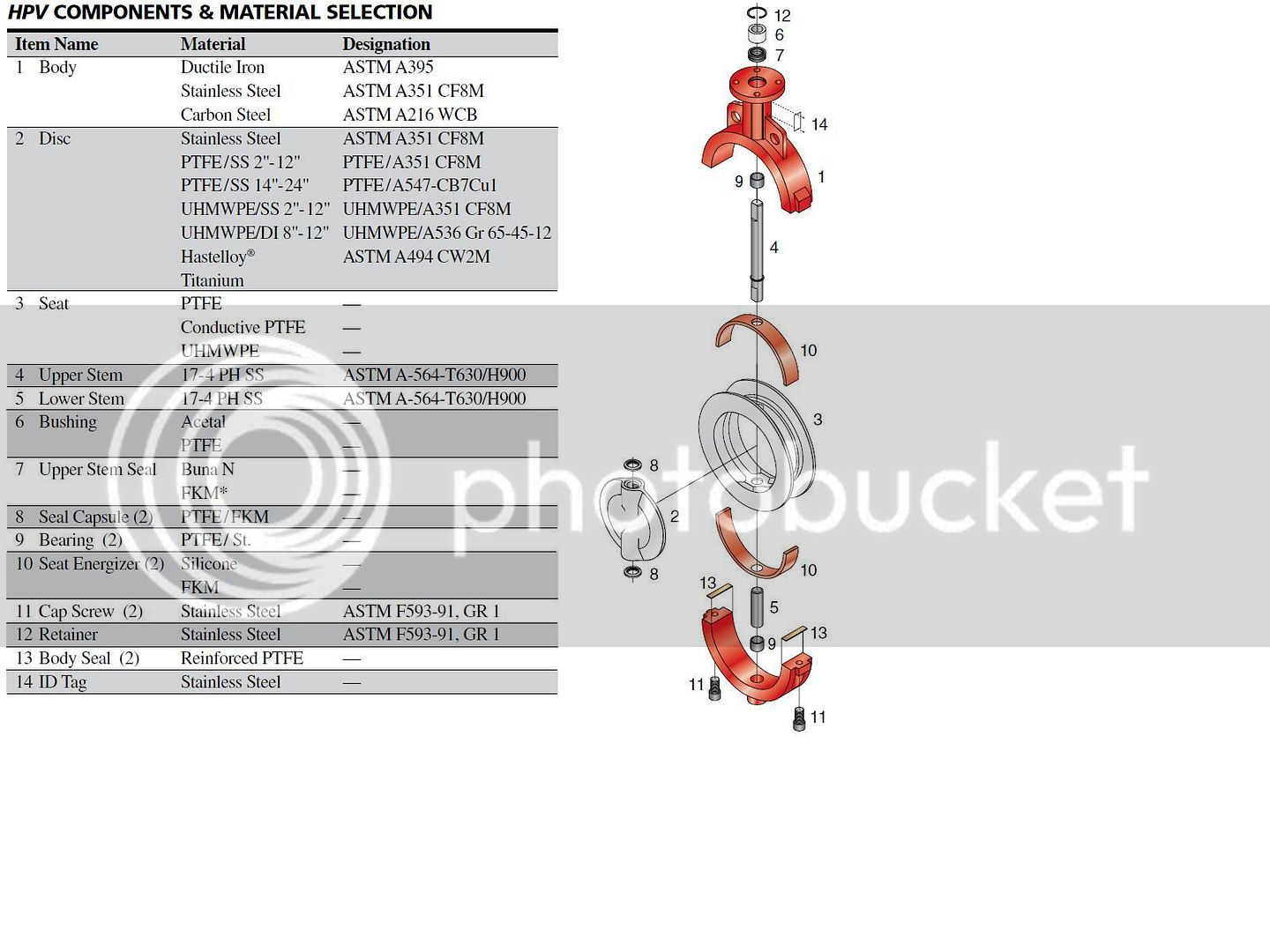

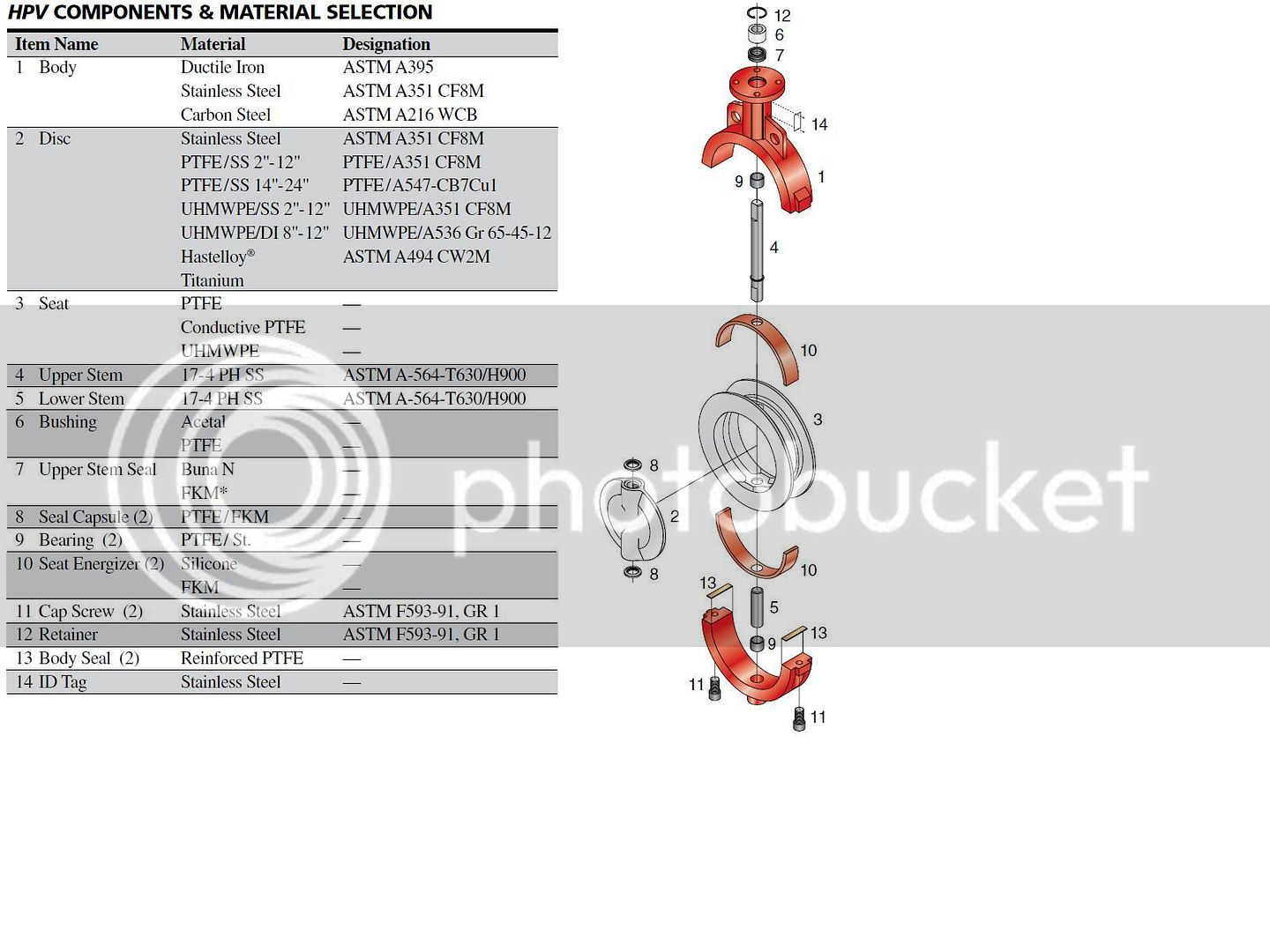

Schmatic:

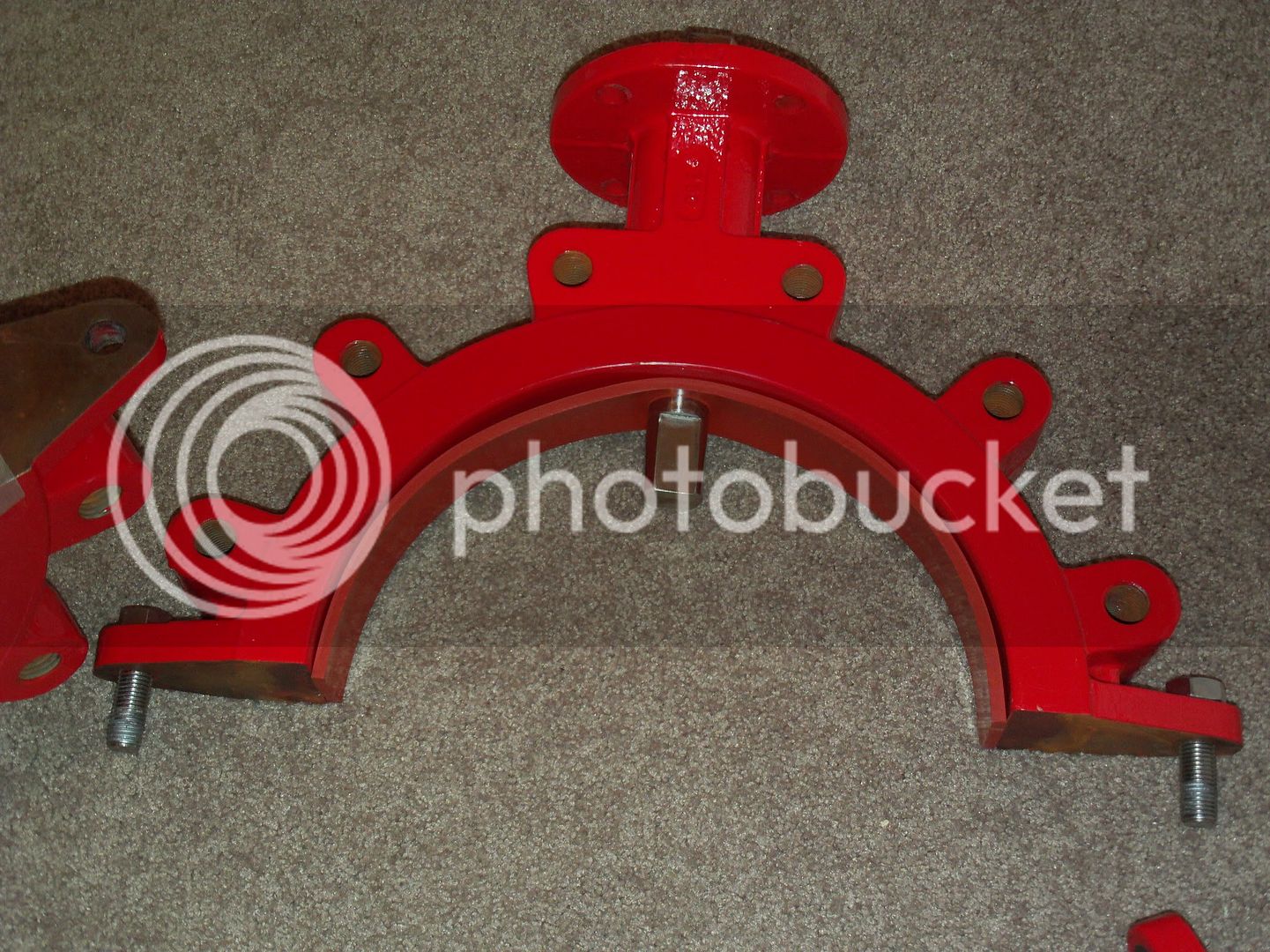

Gear actuator - while this does gear the turning ratio, due to the high friction force, it doesnt make it easier to turn the shaft.

Top housing - this contains the main shaft and is impossible to turn - even without anything attached (I need to take this apart and replace the grease etc to see it it will turn easier) This makes these valves almost unturnable - hopefully a good stem and lube might fix it!

Closeup of the top shaft (where it meets with the geared actuator)

And a closer view

Bottom housing: the lower shaft (the round stainless axel still in place came out of the other one)

Later that day I decided they only way to get them in the house was to take them apart and lift them in piece by piece.

Pics follow:

Schmatic:

Gear actuator - while this does gear the turning ratio, due to the high friction force, it doesnt make it easier to turn the shaft.

Top housing - this contains the main shaft and is impossible to turn - even without anything attached (I need to take this apart and replace the grease etc to see it it will turn easier) This makes these valves almost unturnable - hopefully a good stem and lube might fix it!

Closeup of the top shaft (where it meets with the geared actuator)

And a closer view

Bottom housing: the lower shaft (the round stainless axel still in place came out of the other one)

Bandito

Well-Known Member

- Joined

- 23/1/09

- Messages

- 528

- Reaction score

- 1

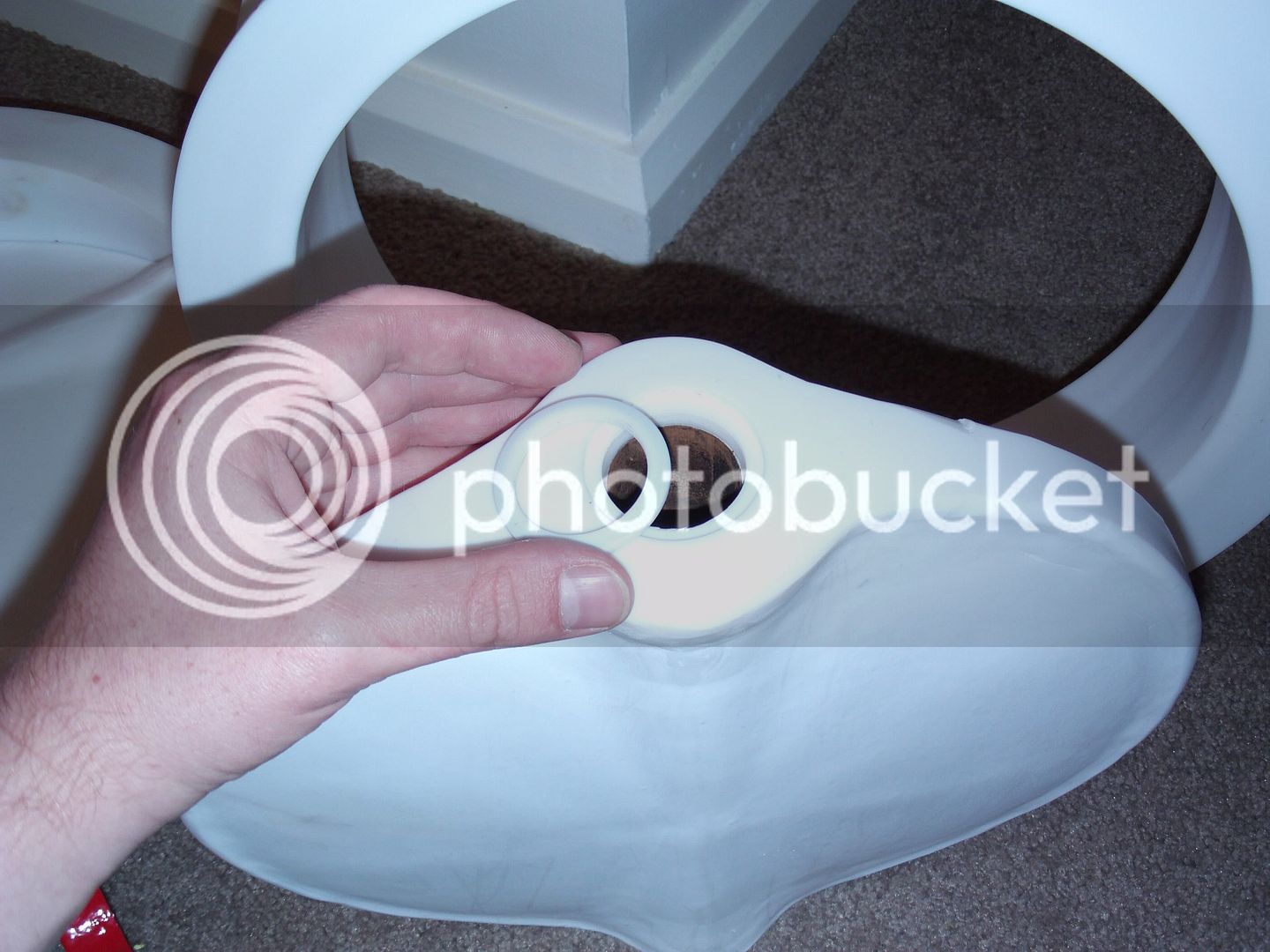

The teflon seat closed

The disk showing the teflon bearing that acts as the main seal

So after all the effort getting the massive weight of these valves over here from the US, I now realise that probably all I needed was the seat and disk (and probably not the steel bodys)!

The way these valves seem to work is by having a relatively solid and hard disk that rotates in a relatively soft seat that can bend and flex and warp to ensure a tight seal - this is where the terracotta colored silicon seat energiser comes into play (No. 10) because it acts as a spring to allow the seat to warp and the hard steel body acts to retard that warping - creating the good seal. The hard steel body acts to provide a base against which the silicon seat energiser works from.

Time will tell if I can just drill holes in the flanges of the teflon seats and do away with the steel bodys.

For those playing along at home, It might be a hell of a lot cheaper to just order replacment seats and disks rather then full valves!

The disk showing the teflon bearing that acts as the main seal

So after all the effort getting the massive weight of these valves over here from the US, I now realise that probably all I needed was the seat and disk (and probably not the steel bodys)!

The way these valves seem to work is by having a relatively solid and hard disk that rotates in a relatively soft seat that can bend and flex and warp to ensure a tight seal - this is where the terracotta colored silicon seat energiser comes into play (No. 10) because it acts as a spring to allow the seat to warp and the hard steel body acts to retard that warping - creating the good seal. The hard steel body acts to provide a base against which the silicon seat energiser works from.

Time will tell if I can just drill holes in the flanges of the teflon seats and do away with the steel bodys.

For those playing along at home, It might be a hell of a lot cheaper to just order replacment seats and disks rather then full valves!

Bandito

Well-Known Member

- Joined

- 23/1/09

- Messages

- 528

- Reaction score

- 1

bandito,

you might want to wait until you have a vessel made before you test the force required to open the butterfly valves the weight of the spent grain might change the force.

it might or it might not just a suggestion.

cheer's matho

Yea, I do expect that to come into play, good call!

slip on or weld neck flange ?

That was a major question before, but now I hope to do away with the thick metal flanges I had intended to use altogether and move towards light ~2mm SS vessels including the flanges. There is still the issue of how to seal the connection, but I am thinking 300mm silicon sheets should be availave from somewhere that can be cut to form a gasket.

Open to suggestions on this one, as I dont know of any.

thelastspud

Well-Known Member

- Joined

- 5/8/09

- Messages

- 254

- Reaction score

- 0

Later that day I decided they only way to get them in the house was to take them apart and lift them in piece by piece.

why? are they really that heavy or what?

Bandito

Well-Known Member

- Joined

- 23/1/09

- Messages

- 528

- Reaction score

- 1

Assembled they were 56kg each without the geared actuator, so about 25+kg for the bottom half and a bit more for the top half - so while I can lift 50kg, I only do it with a weight belt and a bit of training that I am lacking atm.why? are they really that heavy or what?

I am about 10% through the project! I am working to a schedule - middle of august for the first run is the goal. I am now starting to doubt the realisation of that, but thats the purpose of setting an unrealistic goal - to drive one forward that much harder and faster than one would have thought.So I've been following along at home. Quick question, how far through the project are you and when would you expect completion - or first run etc? Are you working to a schedule?

Cheers - Mike

To Do list:

stainless 300mm pipe 450mm long with flanges welded to each end for MLT body and 600mm long for kettle body. Plus gaskets.

300mm False bottom

24V DC, 4.5V DC, 12V DC and 6V DC power supplies.

5 x 8 relay boards.

Mains pressure automated valve.

plate chiller

Tablet dispensers for Hop dispenser carosels (on their way but will require quite a bit of hacking the stepper motors)

Peltier fridge for hop storage.

40L HLT urn

Automated dog food dispensers for grain dispense (now reconsidering the original design which turns out to be Gatlins design that revolutionised the automated sowing of crops and later led to the gatling gun)

Electronic Temperature sensors

Stainless Steel Radiators (not sure if they exist)

60L Stainless conical fermenter.

Hermes.

Stainless mixing arm with motor for MLT

100-150RPM whirlpool motor with stainless impeller.

2 x Butterfly valve actuators

2 x power controllers for HERMS and kettle, and mabee 2 extra ones for heating the 53kg butterflys

yardy

BI3V

- Joined

- 25/2/06

- Messages

- 3,065

- Reaction score

- 10

Assembled they were 56kg each without the geared actuator, so about 25+kg for the bottom half and a bit more for the top half - so while I can lift 50kg, I only do it with a weight belt and a bit of training that I am lacking atm.

I am about 10% through the project! I am working to a schedule - middle of august for the first run is the goal. I am now starting to doubt the realisation of that, but thats the purpose of setting an unrealistic goal - to drive one forward that much harder and faster than one would have thought.

To Do list:

stainless 300mm pipe 450mm long with flanges welded to each end for MLT body and 600mm long for kettle body. Plus gaskets.

300mm False bottom

24V DC, 4.5V DC, 12V DC and 6V DC power supplies.

5 x 8 relay boards.

Mains pressure automated valve.

plate chiller

Tablet dispensers for Hop dispenser carosels (on their way but will require quite a bit of hacking the stepper motors)

Peltier fridge for hop storage.

40L HLT urn

Automated dog food dispensers for grain dispense (now reconsidering the original design which turns out to be Gatlins design that revolutionised the automated sowing of crops and later led to the gatling gun)

Electronic Temperature sensors

Stainless Steel Radiators (not sure if they exist)

60L Stainless conical fermenter.

Hermes.

Stainless mixing arm with motor for MLT

100-150RPM whirlpool motor with stainless impeller.

2 x Butterfly valve actuators

2 x power controllers for HERMS and kettle, and mabee 2 extra ones for heating the 53kg butterflys

how many sq mtr are we talking about here ?

Bandito

Well-Known Member

- Joined

- 23/1/09

- Messages

- 528

- Reaction score

- 1

how many sq mtr are we talking about here ?

probably about 1sq m. All stacked vertically in all 11 dimensions B)

JonnyAnchovy

Well-Known Member

- Joined

- 4/11/08

- Messages

- 875

- Reaction score

- 2

WHAT HAS SCIENCE DONE!?

Similar threads

- Replies

- 1

- Views

- 4K

- Replies

- 11

- Views

- 6K

- Replies

- 4

- Views

- 2K

- Replies

- 1

- Views

- 1K

- Replies

- 88

- Views

- 15K