wareemba

Well-Known Member

- Joined

- 25/11/14

- Messages

- 63

- Reaction score

- 2

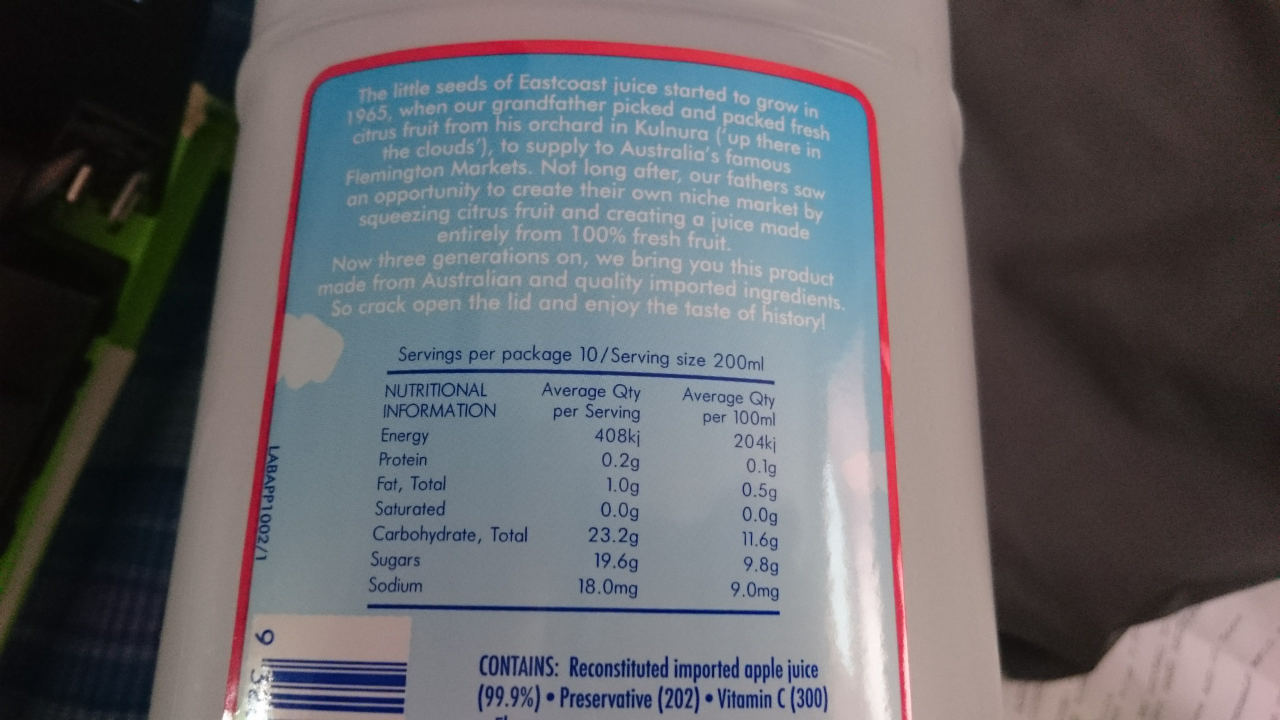

i got 20L of fresh apple juice (unpasteurised, came refrigerated) and put in fermenter and got the temp up to 21 degrees then pitched the Mangrove Jacks MO2 cider yeast and put the lid on.

there are a few bubbles on the top of the juice (like the size of a beer coaster), but the gravity is 1.040, which is what is was when i started...

am i being impatient, is it going to be a slow ferment?

my last cider was supermarket shelf stuff with EC1118 yeast, which cranked along quite hard...

there are a few bubbles on the top of the juice (like the size of a beer coaster), but the gravity is 1.040, which is what is was when i started...

am i being impatient, is it going to be a slow ferment?

my last cider was supermarket shelf stuff with EC1118 yeast, which cranked along quite hard...