gava

I do rather like beer.....

- Joined

- 23/1/09

- Messages

- 1,198

- Reaction score

- 99

Hello All,

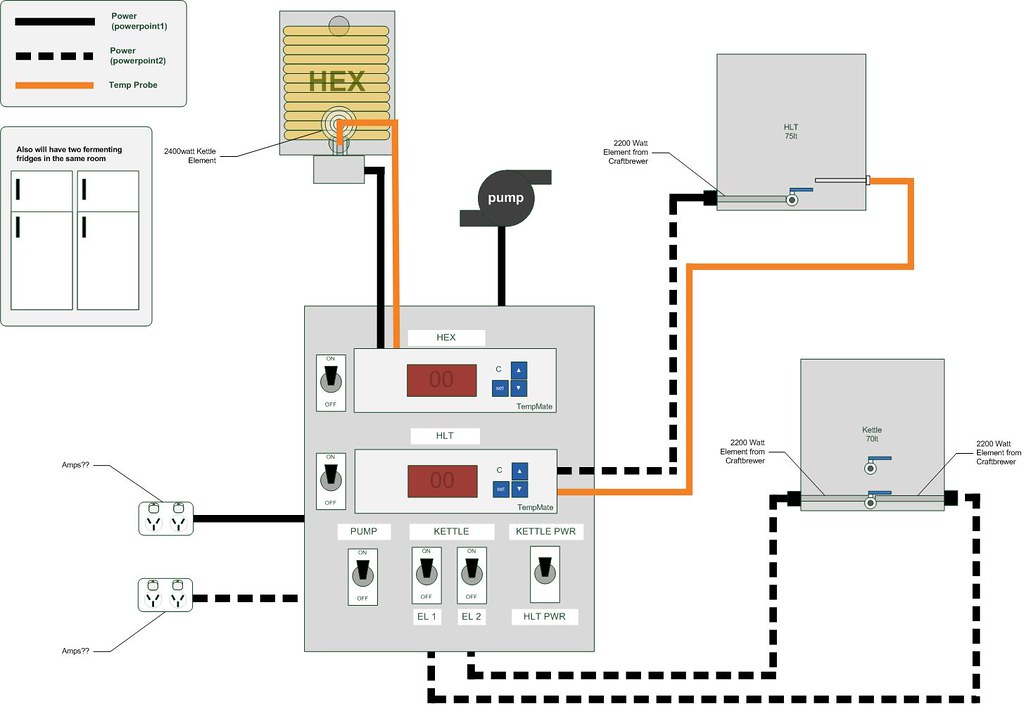

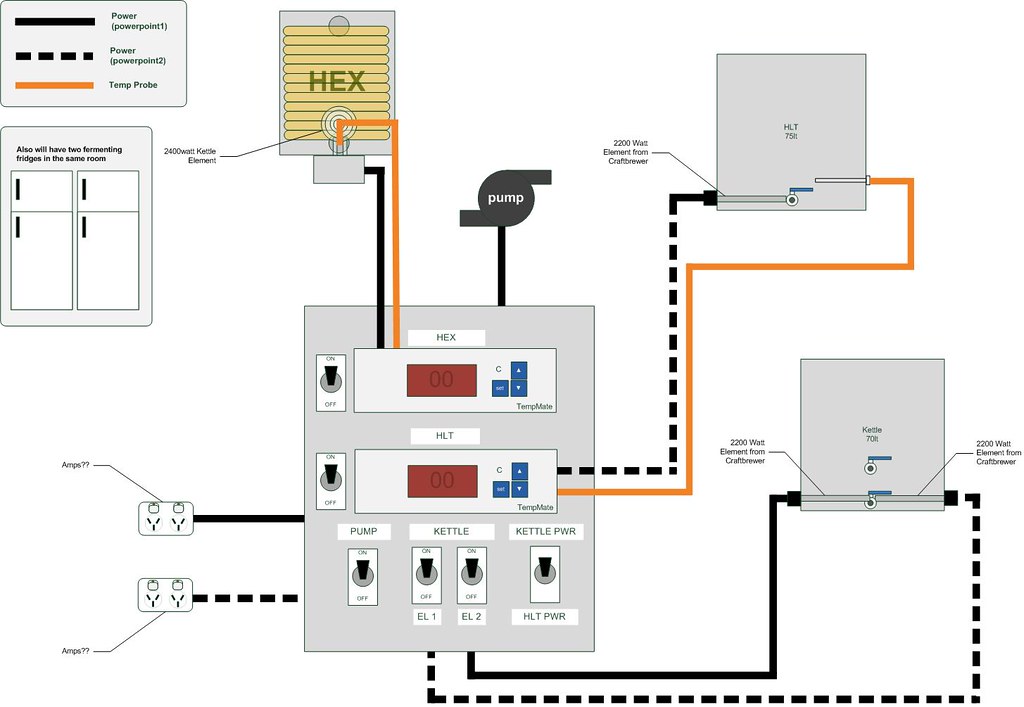

Im in the middle of planning a new house and i've got a room set aside for a brewery. I want to move towards a full eletric brewrig but im not sure what I should plan for as power outlets go in the new room.

What I want my rig to be in the end is full eletric HERMS that can handle double batches. Currently I have a 2400 element in my HERMS pot but im not clear on a good configuration for the kettle/hlt? elements? what power outlet requirements I should have. i.e. Amps etc.. Im not sparky so I would like some feed back that I can go to the builders and say I want x points that are y and they should have this.. that.. bla bla..

Any information would be great.

Im in the middle of planning a new house and i've got a room set aside for a brewery. I want to move towards a full eletric brewrig but im not sure what I should plan for as power outlets go in the new room.

What I want my rig to be in the end is full eletric HERMS that can handle double batches. Currently I have a 2400 element in my HERMS pot but im not clear on a good configuration for the kettle/hlt? elements? what power outlet requirements I should have. i.e. Amps etc.. Im not sparky so I would like some feed back that I can go to the builders and say I want x points that are y and they should have this.. that.. bla bla..

Any information would be great.