matho

The Braumiser

- Joined

- 30/4/08

- Messages

- 1,403

- Reaction score

- 142

Did you try running the pump on only boiling water to see if it is the problem ?well im going to have to replace the pump because im sure it has put a plastic taint in the beer, im going to replace it with a march pump which will just fit and ill be using these QD so i can quickly remove the pump for cleaning and i can use it for my other brewery

View attachment 49330

cheers matho

Did you try running the pump on only boiling water to see if it is the problem ?

Given the plastics it should be FG and stable up to 100c.

Nev

Ok thats interesting, I was going to use one of these pumps (Strontium magnet) for my next project.hey Nev i think its coming from the exposed magnet, i pulled the pump apart a few days ago and there was a little bit of water in it and the smell is the same taste im getting from the beer

cheers steve

no i didn't get in contact with the seller, i did try and email the manufacture but i haven't heard back from them yet, before use i did run PBW thru it at 65 deg for about 30min, maybe im just being a bit paranoid about it, it is a great little pump that fits perfectly, I'm just a bit worried about itOk thats interesting, I was going to use one of these pumps (Strontium magnet) for my next project.

Did your seller confirm they are certified FG ?

Nev

Cheers Matho, I will get one and run some taste test on it.no i didn't get in contact with the seller, i did try and email the manufacture but i haven't heard back from them yet, before use i did run PBW thru it at 65 deg for about 30min, maybe im just being a bit paranoid about it, it is a great little pump that fits perfectly, I'm just a bit worried about it

cheers steve

yep anytime mateLooking great Steve.

Will have to pop round and have a look at it!

I'm an Italian homebrewer new on the forum and looking around to different "braumeister clone" implementation I have discovered this threadvery interesting and one of the closest to the original one !

If you are interested you can see my rig and ideas on this two threads

Brewtroller Forum

BIAB forum

Matho I have a couple of question for youjust to understand how you fix a couple of question that are worrying me

The first point is the sealing of the malt pipe with the external vessel bottomI have tested different solutions with silicon tubing an silicone extrusion but I still have some lack of fluidI'm not able to source a proper silicone gasket with right U channel measurements so I'm still trying to find an alternative solution. Any suggestion is appreciated.

The other point is related to the tempertature probe placementI see in some picture you insert it near the pump inlet (and the heating element) outside the malt pipe. In the original assembly it is internal.. near the pump outletany reason for this choice ?

Thank you in advance for support

regards

Davide

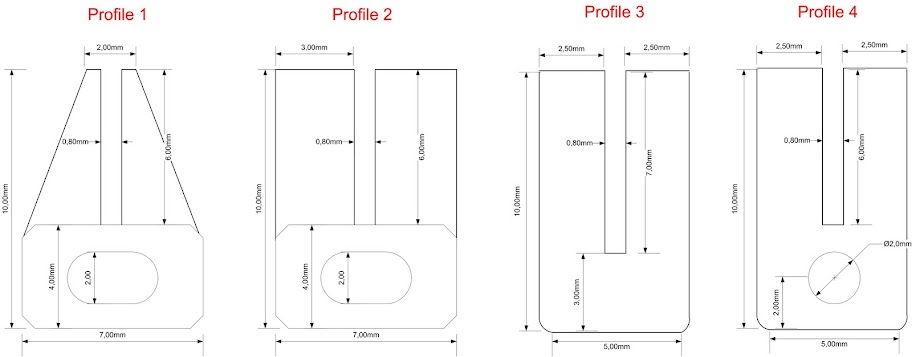

i can't see why 3/8 hose wouldn't work on straight pipe either here is a pic of some 3/8 on a malt pipe i making up if you make it slightly larger than needed then you can make the ends push against each other ( i need to order more hose from craftbrewer)

View attachment 49364

cheers steve