my point is that it has GPIOs , has even more memory than arduino and is capable of running on same software plus something which willl utilize the WiFi capability. Because from what I have seen on instructables you can use it in the same way as Arduino. Of course you will need new PCB or cable connectors to existing boards.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Brauduino (Matho’s Controller) Build/Advice/Question Thread

- Thread starter SBOB

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

MastersBrewery

Journeyman, the learning never stops

- Joined

- 7/6/11

- Messages

- 2,319

- Reaction score

- 683

ok so your talking a specific board the WesMos D1.terragady said:my point is that it has GPIOs , has even more memory than arduino and is capable of running on same software plus something which willl utilize the WiFi capability. Because from what I have seen on instructables you can use it in the same way as Arduino. Of course you will need new PCB or cable connectors to existing boards.

Yup nice piece of kit but note it has only one analog pin. Now I don't remember pin assignments off the top of my head but I dare say you'd need to play a little with what is going where. And that particular board would not work with brewpi (chip set thing).

you need analog for buttons and LCD, but both can be connected for example via I2C protocol/connector and its pretty straightforward. I think http://vito.tw/ is using I2C for LCD but probably not for buttons, anyway there is an shield with LCD and buttons where only 2 pins are required from uC (thats I2C pins).

I was not talking about specific WesMos although I have D2 mini. Any ESP module has those GPIOs etc, so the board like WesMos is only for simplicity and provide USB programmer, other potentials etc, but of course you can use just simple ESP naked module, but thats harder to wire.

I was not talking about specific WesMos although I have D2 mini. Any ESP module has those GPIOs etc, so the board like WesMos is only for simplicity and provide USB programmer, other potentials etc, but of course you can use just simple ESP naked module, but thats harder to wire.

I had my controller wired up ,except for the sensor as I required a different sensor for my HERMS system.

It was working ok, ie could program it etc.

Removed the cover to wire up a new sensor and tested again.

With 240v tall I got was a lit but blank screen.

Disconnected the 240v from the front of the controller and powered up using USB.

Now get the image above. 2 rows of white blocks.

Any clues???

Hi gap

Yep I have had that too at one time or other.

I would suggest lots of checking

Check that the arduino is plugged in correctly to the shield. I plugged mine in backwards after pulling it off to answer a question and put it backwards and never to work again.

Check the power to the board

Check the 5v

Check the leds on the arduino

Can try reprogramming the arduino

I think the probable fix will be a new arduino. They are reasonably robust but they can be killed with static, or plugging in the wrong way etc. I have seen a soldering iron kill things as the tip is generally grounded and if the board has leakage to another circuit it will blow stuff up.

I have piles of arduinos here and last knight i pulled 2 brand new ones out of the packet and one will not accept program at all! The other is not running correctly. They are cheap ones ex china and I guess you get what you pay for.

Depending on your level of skill and available tools And location I am happy to assist in fault finding.

James

Zwitter

Sent from my iPad using Tapatalk HD

Yep I have had that too at one time or other.

I would suggest lots of checking

Check that the arduino is plugged in correctly to the shield. I plugged mine in backwards after pulling it off to answer a question and put it backwards and never to work again.

Check the power to the board

Check the 5v

Check the leds on the arduino

Can try reprogramming the arduino

I think the probable fix will be a new arduino. They are reasonably robust but they can be killed with static, or plugging in the wrong way etc. I have seen a soldering iron kill things as the tip is generally grounded and if the board has leakage to another circuit it will blow stuff up.

I have piles of arduinos here and last knight i pulled 2 brand new ones out of the packet and one will not accept program at all! The other is not running correctly. They are cheap ones ex china and I guess you get what you pay for.

Depending on your level of skill and available tools And location I am happy to assist in fault finding.

James

Zwitter

Sent from my iPad using Tapatalk HD

MastersBrewery

Journeyman, the learning never stops

- Joined

- 7/6/11

- Messages

- 2,319

- Reaction score

- 683

Has the back light POT been adjusted?

Yes it was the first thing I checked but I will check it again tonight.MastersBrewery said:Has the back light POT been adjusted?

Thanks for the reply

I have pulled it apart.

Disconnected from the 240v.

Disconnected the button leads

Tried to disconnect the lcd from the board without success.

I have just plugged it it in using USB and it worked!!!!!!!!!!!!!!!!!!

I will reassemble it in stages and test at each stage.

Hello James, missed seeing your reply. Thanks for the tips.

If I get into more trouble with it i will contact you.

Fingers crossed

Graeme

Disconnected from the 240v.

Disconnected the button leads

Tried to disconnect the lcd from the board without success.

I have just plugged it it in using USB and it worked!!!!!!!!!!!!!!!!!!

I will reassemble it in stages and test at each stage.

Hello James, missed seeing your reply. Thanks for the tips.

If I get into more trouble with it i will contact you.

Fingers crossed

Graeme

claypot

Well-Known Member

- Joined

- 9/5/11

- Messages

- 155

- Reaction score

- 38

Hi all,

I've finally assembled my unit and its awesome, thanks to all involved!

For my build I require a longer temp probe, I gather it is a standard PT100 RTD?

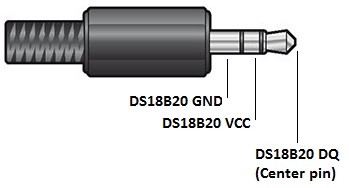

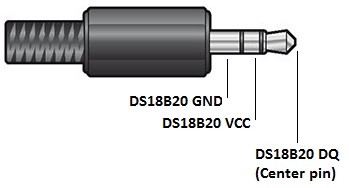

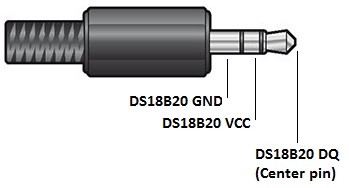

So, does anyone know what the wiring configuration is to the audio connector jack?

As I will most likely get the PT100 required and wire to the same style audio plug.

eg red wire to front, white to middle, black to back or the likes?

Cheers,

Clayton.

I've finally assembled my unit and its awesome, thanks to all involved!

For my build I require a longer temp probe, I gather it is a standard PT100 RTD?

So, does anyone know what the wiring configuration is to the audio connector jack?

As I will most likely get the PT100 required and wire to the same style audio plug.

eg red wire to front, white to middle, black to back or the likes?

Cheers,

Clayton.

MastersBrewery

Journeyman, the learning never stops

- Joined

- 7/6/11

- Messages

- 2,319

- Reaction score

- 683

No mate, you need a ds18b20, that is unless you want to rewrite the software.claypot said:Hi all,

I've finally assembled my unit and its awesome, thanks to all involved!

For my build I require a longer temp probe, I gather it is a standard PT100 RTD?

So, does anyone know what the wiring configuration is to the audio connector jack?

As I will most likely get the PT100 required and wire to the same style audio plug.

eg red wire to front, white to middle, black to back or the likes?

Cheers,

Clayton.

MB

claypot

Well-Known Member

- Joined

- 9/5/11

- Messages

- 155

- Reaction score

- 38

Hey MB,

Cheers mate, nope don't fancy any software mods I have enough drama with English as a first language!

I had a quick look at ds18b20 probes and doesn't look like they are available at the length I need.

So will have to come up with another option, most likely another probe into the top of the malt pipe. Then switch over for the boil.

I should of got the extra probe with the kit...

Do the pre made sensors with the 3.5mm audio jack all use the same wiring configuration?

Cheers mate, nope don't fancy any software mods I have enough drama with English as a first language!

I had a quick look at ds18b20 probes and doesn't look like they are available at the length I need.

So will have to come up with another option, most likely another probe into the top of the malt pipe. Then switch over for the boil.

I should of got the extra probe with the kit...

Do the pre made sensors with the 3.5mm audio jack all use the same wiring configuration?

MastersBrewery

Journeyman, the learning never stops

- Joined

- 7/6/11

- Messages

- 2,319

- Reaction score

- 683

You could be in luck that fantastic piece of kit known as brewtroller has recently relaunched if they don't have probes in their store now they will soon. I'm on the phone right now but google brewtroller and you should be in business. Why the need for the long probe? Temp is best measured at the hotest liquor temp ie close to the element.claypot said:Hey MB,

Cheers mate, nope don't fancy any software mods I have enough drama with English as a first language!

I had a quick look at ds18b20 probes and doesn't look like they are available at the length I need.

So will have to come up with another option, most likely another probe into the top of the malt pipe. Then switch over for the boil.

I should of got the extra probe with the kit...

Do the pre made sensors with the 3.5mm audio jack all use the same wiring configuration?

MB

claypot

Well-Known Member

- Joined

- 9/5/11

- Messages

- 155

- Reaction score

- 38

Hey MB,

My rig is a bit different to others, I've got a 3kw coiled element in the middle of the kettle and the malt pipe sits over it.

The probe in the Brauduino (Matho’s Controller) kit isn't long enough to sit above the element.

So I don't think it would sense the temp of the wort flowing into the malt pipe as it passes the element as accurately as I would like.

My build link here: http://aussiehomebre...83#entry1196086

And follow up with new malt pipe and top plate: http://aussiehomebrewer.com/topic/57924-braumeister-nextgen-build/?p=1242570

Just checked out the brewtroller, looks pretty cool especially for people who now what their doing!

It gave me the idea of putting a shorter probe into a thermo well, so long as I can protect the cable from the heat.

Looking at those prices though you really get an appreciation for all the awesome work Lael has put in to the kit!

My rig is a bit different to others, I've got a 3kw coiled element in the middle of the kettle and the malt pipe sits over it.

The probe in the Brauduino (Matho’s Controller) kit isn't long enough to sit above the element.

So I don't think it would sense the temp of the wort flowing into the malt pipe as it passes the element as accurately as I would like.

My build link here: http://aussiehomebre...83#entry1196086

And follow up with new malt pipe and top plate: http://aussiehomebrewer.com/topic/57924-braumeister-nextgen-build/?p=1242570

Just checked out the brewtroller, looks pretty cool especially for people who now what their doing!

It gave me the idea of putting a shorter probe into a thermo well, so long as I can protect the cable from the heat.

Looking at those prices though you really get an appreciation for all the awesome work Lael has put in to the kit!

Hi Clayton,

As long as you have sufficient wort movement you should find that your temperatures will be accurate. If you heat with only water in the pot, without any movement you will find you might get temperature stratification. Simply splashing the water around will show you roughly how much water movement you need. Normally it is not much.

I'm glad you like the kit!

As long as you have sufficient wort movement you should find that your temperatures will be accurate. If you heat with only water in the pot, without any movement you will find you might get temperature stratification. Simply splashing the water around will show you roughly how much water movement you need. Normally it is not much.

I'm glad you like the kit!

Hi Claypot

You can build your own probe depending on your skills.

The DS18b20 can be bought cheap as and then you get stainless pipe and get the end welded up and some thing on other end and put thermal grease on the sensor and push it all the way to the end of the closed tube and then fill behind it with silicone.

Put a plg on and bob is your fathers bother.

I have made several and in fact repaired a few after hooking them up incorrectly so replaced the sensor in the fittings.

There are places that can fabricate them for you but the cost gets outrageous fairly quickly.

James

Sent from my iPad using Tapatalk HD

You can build your own probe depending on your skills.

The DS18b20 can be bought cheap as and then you get stainless pipe and get the end welded up and some thing on other end and put thermal grease on the sensor and push it all the way to the end of the closed tube and then fill behind it with silicone.

Put a plg on and bob is your fathers bother.

I have made several and in fact repaired a few after hooking them up incorrectly so replaced the sensor in the fittings.

There are places that can fabricate them for you but the cost gets outrageous fairly quickly.

James

Sent from my iPad using Tapatalk HD

claypot

Well-Known Member

- Joined

- 9/5/11

- Messages

- 155

- Reaction score

- 38

Hey Lael,

Cheers mate, yeah I guess I do have a lot of movement under the malt pipe with the whirlpool fitting, so maybe worrying about nothing.

I am chasing some crappy mash efficiencies though high 60% to low 70%.

Mashing low and high hasn't seemed to make a difference so probably not temp related.

I think using your kit with the pump rests will help.

I might experiment with my whirlpool fitting too, it may be sending preferential flow up the side due to centrifugal force..

I might do a mash with it removed.

Cheers James,

That sounds like the go. As my current rig has a 1/4 or 3/8 BSP (can't remember which) probe, I'm hoping to use the same welded in socket.

So I'll fabricate one as you suggested.

Can you confirm the wiring diagram for the 3.5mm audio jack I attached is correct for this application?

Thanks again,

Clayton

Cheers mate, yeah I guess I do have a lot of movement under the malt pipe with the whirlpool fitting, so maybe worrying about nothing.

I am chasing some crappy mash efficiencies though high 60% to low 70%.

Mashing low and high hasn't seemed to make a difference so probably not temp related.

I think using your kit with the pump rests will help.

I might experiment with my whirlpool fitting too, it may be sending preferential flow up the side due to centrifugal force..

I might do a mash with it removed.

Cheers James,

That sounds like the go. As my current rig has a 1/4 or 3/8 BSP (can't remember which) probe, I'm hoping to use the same welded in socket.

So I'll fabricate one as you suggested.

Can you confirm the wiring diagram for the 3.5mm audio jack I attached is correct for this application?

Thanks again,

Clayton

I just had another look at your rig. It doesn't look like you've got any where near enough open space to let water permeate through the entire grain bed and back out easily - I would be replacing the plates with perf stainless if possible - just as a piece of advice from my experience - the bottom plate only needs to be strong enough to hold the weight of the grain when removing from the malt pipe. I believe that the top plate needs to be quite a bit stronger than the bottom one. Of course, having them the same makes it easier to use.

I would be looking at your grain crush as the 2nd most important factor - how are you cracking it?

I would be looking at your grain crush as the 2nd most important factor - how are you cracking it?

claypot

Well-Known Member

- Joined

- 9/5/11

- Messages

- 155

- Reaction score

- 38

Cheers mate, Yeah I was trying to do it on the cheap...

The bottom plate is just a mesh splatter screen which I thought would be o.k. But the slotted stainless plate at the top doesn't allow as much flow as perf plate I agree. Might have to part with some cash..

I'm using a mashmaster mill with the motion dynamics motor.

I originally set the mill to 1.2mm and checked it last brew and found it was around 1.1mm so set it back to 1.2mm and seemed a bit better as far as the flow and grain compaction went.

The bottom plate is just a mesh splatter screen which I thought would be o.k. But the slotted stainless plate at the top doesn't allow as much flow as perf plate I agree. Might have to part with some cash..

I'm using a mashmaster mill with the motion dynamics motor.

I originally set the mill to 1.2mm and checked it last brew and found it was around 1.1mm so set it back to 1.2mm and seemed a bit better as far as the flow and grain compaction went.

Yeah, my builds were painful for the hip pocket. The first time I decided to drill the holes in the plate... A sore arm, three afternoons and something like 500 holes later I decided that was stupid.

Whereabouts are you located?

edit: do you have the new fluted rollers? I've got the knurled ones and tempted to upgrade... The crush I saw come out of some of the fluted ones looked amazing.

Whereabouts are you located?

edit: do you have the new fluted rollers? I've got the knurled ones and tempted to upgrade... The crush I saw come out of some of the fluted ones looked amazing.

or just wait till Lael does a pot/malt-pipe/perf-sheet bulk buy... i think its planned for 2018claypot said:But the slotted stainless plate at the top doesn't allow as much flow as perf plate I agree. Might have to part with some cash..

Similar threads

Equipment For Sale

Brauduino, 5Star Elements, Pump, Big Pot.

- Replies

- 3

- Views

- 2K

- Replies

- 2

- Views

- 1K