markws

Well-Known Member

- Joined

- 8/12/03

- Messages

- 255

- Reaction score

- 3

Dear All,

I know that I have aske about this previously and others have continued to probe this question, but I still doo not feel that I have a full grasp of this situation.

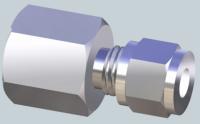

Question: Can you (actually) by a 1/2" stainless compression nut.

Following previous threads and talking to distributors - the only way to intergrate a stainless compression fitting onto a 1/2" BSP thread is to use an adaptor (to attach to the 1/2" BSP threaded pipe and compression fitting).

Therefore the closest we are able to get to a brass 1/2 BSP compression nut and olive fitting is a chrome plated brass compression nut.

Am I correct or am completely off centre?

Any help - distributors, part numbers etc would be very much appreciated

thanks in advance

Mark WS

I know that I have aske about this previously and others have continued to probe this question, but I still doo not feel that I have a full grasp of this situation.

Question: Can you (actually) by a 1/2" stainless compression nut.

Following previous threads and talking to distributors - the only way to intergrate a stainless compression fitting onto a 1/2" BSP thread is to use an adaptor (to attach to the 1/2" BSP threaded pipe and compression fitting).

Therefore the closest we are able to get to a brass 1/2 BSP compression nut and olive fitting is a chrome plated brass compression nut.

Am I correct or am completely off centre?

Any help - distributors, part numbers etc would be very much appreciated

thanks in advance

Mark WS