Impy

Well-Known Member

- Joined

- 30/12/09

- Messages

- 130

- Reaction score

- 12

[SIZE=10.5pt]After creating a simple 50L electric BIAB single vessel system fairly early in my home brewing days I've since spawned two smaller versions of myself that severely cut down the time I have for brewing. There are also a few issues I have with the larger pots brew design and [/SIZE]subsequent[SIZE=10.5pt] process limitations that make the pot frustrating to use, so hopefully I can address those with the new system. So now the goal is to assemble the best / cheapest / most streamlined single vessel system that I can. [/SIZE]

Goals[SIZE=10.5pt][/SIZE]

[SIZE=10.5pt]Fast brewing process[/SIZE]

[SIZE=10.5pt]Simple brewing process[/SIZE]

[SIZE=10.5pt]Minimise water usage[/SIZE]

[SIZE=10.5pt]Minimise wasted wort[/SIZE]

[SIZE=10.5pt]Cheap (<$500)

[/SIZE]

[SIZE=10.5pt] [/SIZE]

[SIZE=10.5pt]So with these goals in mind I've decided to create a small batch system (10L in fermenter) to reduce time waiting for water to heat up. BIAB obviously. I'd like a recirculating system to reduce trub as much as possible which was a big problem in the larger system. And also using the recirculation to accurately maintain mash temp. Also in the interests of saving time, I'm moving to no-chill.

The Design[/SIZE]

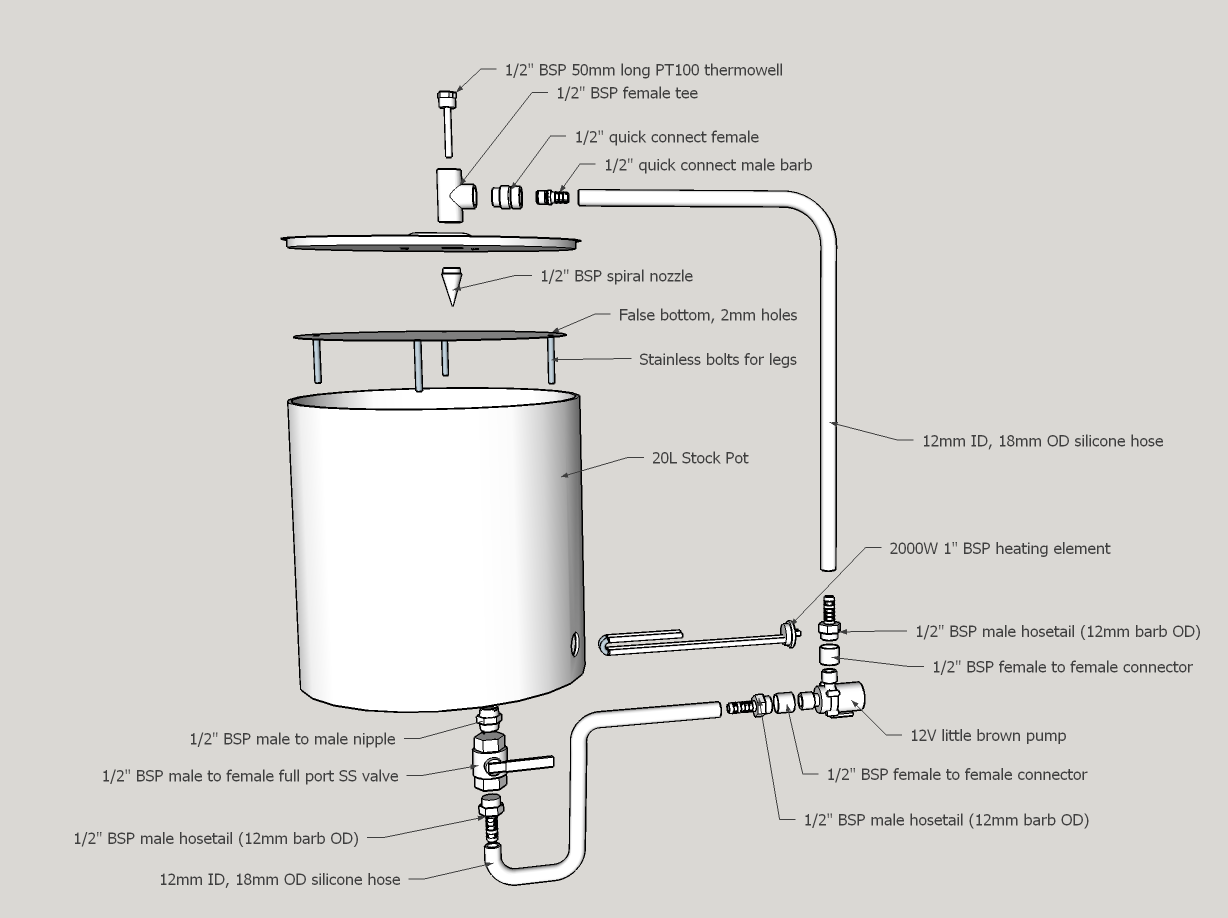

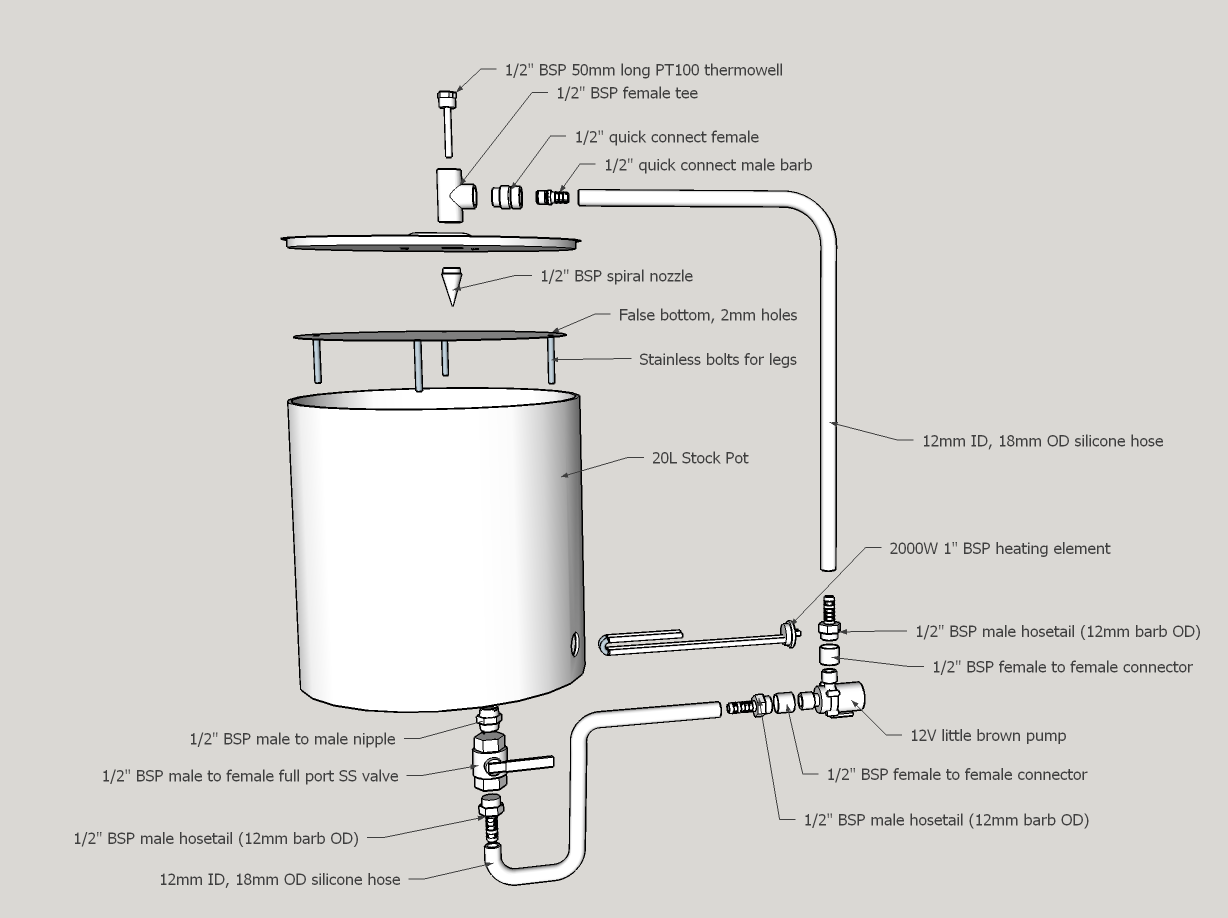

[SIZE=10.5pt]Credit to the system that was my main inspiration for this design. Not sure exactly who made this but it's one of you guys![/SIZE]

[SIZE=10.5pt]Changes I made are to the design:

1. Only port the bottom of the pot rather than put in a drainage valve on the side. Fingers crossed that the recirculation + a whirlpool will be enough to reduce trub volume and maximise wort recovery. [/SIZE]

[SIZE=10.5pt]2. Use a tee fitting on the lid so I could combine the thermowell and the return into one. [/SIZE]

[SIZE=10.5pt]3. Use a false bottom rather than a crab pot (mainly due to the inability to find one of the right size)[/SIZE]

[SIZE=10.5pt]4. Use a 2000W hot water element rather than kmart kettle elements.[/SIZE]

[SIZE=10.5pt]5. Only use stainless parts[/SIZE]

[SIZE=10.5pt] [/SIZE]

[SIZE=10.5pt]Parts list (All stainless parts are 304SS as far as i know)[/SIZE]

20L SS Pot: $80.00

SS False Bottom: $45.00

2000W 1" BSP hot water element: $15.00

1" BSP nut: $1.00

1/2" BSP full port valve: $10.99

1/2" BSP Nipple: $1.00

1/2" BSP nut: $1.49

SS 1/2" BSP female to female pipe x2: $3.38

SS 1/2" BSP Female tee: $4.00

SS 1/2" BSP male thread spiral nozzle: $11.00

SS 1/2" 12mm BSP male hosetail x3: $12.00

2m 12mm silicone tube: $20.00

SS 1/2" Barb male quick connect: $8.00 <-- this is the only place i've found stainless quick connects. Very excited about seeing if these work as expected.

SS 1/2" Male BSP Quick Connect female: $12.00

12V little brown pump: $30.00

1/2" thermowell Pt100: $15.00

Pot and plumbing total: $270

I'm currently waiting for the parts to arrive and i'll post progress pics as it all happens.

'm also putting together a control panel based on the "High Gravity brewing" panel (PID temp control with switches for pump, element, and a dimmer to control boil) which I will update this post with design and parts as I get my head around it.

Goals[SIZE=10.5pt][/SIZE]

[SIZE=10.5pt]Fast brewing process[/SIZE]

[SIZE=10.5pt]Simple brewing process[/SIZE]

[SIZE=10.5pt]Minimise water usage[/SIZE]

[SIZE=10.5pt]Minimise wasted wort[/SIZE]

[SIZE=10.5pt]Cheap (<$500)

[/SIZE]

[SIZE=10.5pt] [/SIZE]

[SIZE=10.5pt]So with these goals in mind I've decided to create a small batch system (10L in fermenter) to reduce time waiting for water to heat up. BIAB obviously. I'd like a recirculating system to reduce trub as much as possible which was a big problem in the larger system. And also using the recirculation to accurately maintain mash temp. Also in the interests of saving time, I'm moving to no-chill.

The Design[/SIZE]

[SIZE=10.5pt]Credit to the system that was my main inspiration for this design. Not sure exactly who made this but it's one of you guys![/SIZE]

[SIZE=10.5pt]Changes I made are to the design:

1. Only port the bottom of the pot rather than put in a drainage valve on the side. Fingers crossed that the recirculation + a whirlpool will be enough to reduce trub volume and maximise wort recovery. [/SIZE]

[SIZE=10.5pt]2. Use a tee fitting on the lid so I could combine the thermowell and the return into one. [/SIZE]

[SIZE=10.5pt]3. Use a false bottom rather than a crab pot (mainly due to the inability to find one of the right size)[/SIZE]

[SIZE=10.5pt]4. Use a 2000W hot water element rather than kmart kettle elements.[/SIZE]

[SIZE=10.5pt]5. Only use stainless parts[/SIZE]

[SIZE=10.5pt] [/SIZE]

[SIZE=10.5pt]Parts list (All stainless parts are 304SS as far as i know)[/SIZE]

20L SS Pot: $80.00

SS False Bottom: $45.00

2000W 1" BSP hot water element: $15.00

1" BSP nut: $1.00

1/2" BSP full port valve: $10.99

1/2" BSP Nipple: $1.00

1/2" BSP nut: $1.49

SS 1/2" BSP female to female pipe x2: $3.38

SS 1/2" BSP Female tee: $4.00

SS 1/2" BSP male thread spiral nozzle: $11.00

SS 1/2" 12mm BSP male hosetail x3: $12.00

2m 12mm silicone tube: $20.00

SS 1/2" Barb male quick connect: $8.00 <-- this is the only place i've found stainless quick connects. Very excited about seeing if these work as expected.

SS 1/2" Male BSP Quick Connect female: $12.00

12V little brown pump: $30.00

1/2" thermowell Pt100: $15.00

Pot and plumbing total: $270

I'm currently waiting for the parts to arrive and i'll post progress pics as it all happens.

'm also putting together a control panel based on the "High Gravity brewing" panel (PID temp control with switches for pump, element, and a dimmer to control boil) which I will update this post with design and parts as I get my head around it.

Last edited by a moderator: