zephon

Well-Known Member

- Joined

- 5/8/08

- Messages

- 115

- Reaction score

- 0

Hi All,

I have plumbed my March pump using the instructions from this blog.

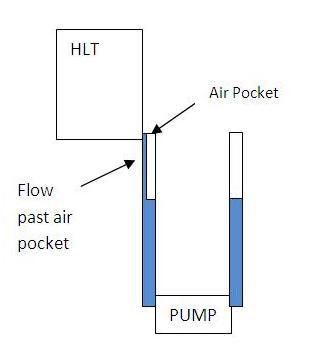

The main problem I have is getting rid of the air trapped in lines that are connected dry. I always seem to end up with a 10-20cm air pocket at the top of the input tube that I can't get rid of without following the steps below.

To prime using this setup I have to do the following (let's say I'm transferring from HLT to MT):

The main problem I have is step #3. Getting rid of that air pocket in the line in this way seems dangerous. It wouldn't take too much of a lapse in concentration to end up with boiling liquid flowing out the end of the output tube and landing who knows where . Originally I thought I wouldn't need step 3 but so far I haven't figured out any other way to get rid of that air pocket.

. Originally I thought I wouldn't need step 3 but so far I haven't figured out any other way to get rid of that air pocket.

So, am I missing something? How do you guys prime yer pumps?

I have plumbed my March pump using the instructions from this blog.

The main problem I have is getting rid of the air trapped in lines that are connected dry. I always seem to end up with a 10-20cm air pocket at the top of the input tube that I can't get rid of without following the steps below.

To prime using this setup I have to do the following (let's say I'm transferring from HLT to MT):

- Connect input side of pump to HLT outlet.

- Open HLT valve, MT valve and output valve on pump, allow water to flow from HLT, through pump, to output hose.

- Before the water flows out the end of the output hose, raise the end of the tube to above the level of the liquid in the HLT. This forces liquid back up the line and pushes the air pocket up through the HLT.

- Close the output valve on the pump.

- Open the bleed valve on the pump slightly to allow any last remaining air in the pump head to escape. Catch and recycle any water that comes out (only a small amount).

- Start the pump, open the output valve to the required amount and pump.

The main problem I have is step #3. Getting rid of that air pocket in the line in this way seems dangerous. It wouldn't take too much of a lapse in concentration to end up with boiling liquid flowing out the end of the output tube and landing who knows where

So, am I missing something? How do you guys prime yer pumps?