Using a second ssr to switch the pump wont fix the problem because it is the 240v causing the scrambling. You may also find that the element switching on and off causes the scramble. If you cant re route your wiring try getting some shielded cable and connext the shield to earth. It may help but if the wiring is that bad it may not either.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Matho's controller

- Thread starter MastersBrewery

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

This isn't true. The element is a resistive load vs an inductive load which has a different pattern for drawing current.

The combination of switching 240v for a motor/pump through a relay on the board causes chatter/arcing which creates the scrambling. SSRs provide isolation between the AC and DC and so would also deal with the issue by removing the 'chatter' and by preventing the 240v from interacting with the board. SSRs (that we are using) also switch at zero on the AC wave, which means even if the SSR switches do 'chatter' its still a 'clean' switch.

So why stick with the current design? It provides flexibility - you can use a DC pump OR an AC pump, it's compact which allows us to fit 2xSSRs in the box for heating which makes the unit great for bigger or faster batches, and it works.

We've tested the boards thoroughly and the emf shielding through the snubber circuit and board design provided has worked with chugger, march and kaixin/kegking pumps without scrambling. But... If you are sloppy with your wiring, then yeah, you might still get issues.

I haven't tried this - but if you really want to use an SSR for the 240v side of the pump, you should be able to run 12v out from the power supply into the relay (pump terminal) on the board and then out to the +ve DC side of the SSR, then run the -ve side of the DC side of the SSR back to the -ve of the power supply. The relay will switch the DC on and off, which will trigger the SSR, which will switch the 240v pump. Please note you can't use a single SSR to switch both heat and pump at the same time.

Or... You could just be neat with your wiring

Of course... If your wiring is neat and you are still having issues - PM me and I'll help.

The combination of switching 240v for a motor/pump through a relay on the board causes chatter/arcing which creates the scrambling. SSRs provide isolation between the AC and DC and so would also deal with the issue by removing the 'chatter' and by preventing the 240v from interacting with the board. SSRs (that we are using) also switch at zero on the AC wave, which means even if the SSR switches do 'chatter' its still a 'clean' switch.

So why stick with the current design? It provides flexibility - you can use a DC pump OR an AC pump, it's compact which allows us to fit 2xSSRs in the box for heating which makes the unit great for bigger or faster batches, and it works.

We've tested the boards thoroughly and the emf shielding through the snubber circuit and board design provided has worked with chugger, march and kaixin/kegking pumps without scrambling. But... If you are sloppy with your wiring, then yeah, you might still get issues.

I haven't tried this - but if you really want to use an SSR for the 240v side of the pump, you should be able to run 12v out from the power supply into the relay (pump terminal) on the board and then out to the +ve DC side of the SSR, then run the -ve side of the DC side of the SSR back to the -ve of the power supply. The relay will switch the DC on and off, which will trigger the SSR, which will switch the 240v pump. Please note you can't use a single SSR to switch both heat and pump at the same time.

Or... You could just be neat with your wiring

Of course... If your wiring is neat and you are still having issues - PM me and I'll help.

MitchD said:Using a second ssr to switch the pump wont fix the problem because it is the 240v causing the scrambling. You may also find that the element switching on and off causes the scramble. If you cant re route your wiring try getting some shielded cable and connext the shield to earth. It may help but if the wiring is that bad it may not either.

The ac voltage is the problem. Induced voltage created by the 240v ac is what is causing the scrambling, weather its a resistive or inductive load makes no difference. The use of ssr or relay makes no difference.

If the load side of either the pump or element is ran parallel to the screen wiring it will induce a small amount of ac voltage into that wiring scrambling the screen, turning that ac load off wont fix the scrambled screen because it doesnt have time based reset written into the code.

I'm sure you have done some strenuous testing and you are correct that neat wiring is the way to fix the problem. I wasnt part of you bulk buy because i was impatient and capable of building and assembling it on my own, I built my own by following the schematics posted by matho and max.

While testing (very sloppy wiring) I had a scrambling problem while only using the element run off the same type of ssr you are using.

If the load side of either the pump or element is ran parallel to the screen wiring it will induce a small amount of ac voltage into that wiring scrambling the screen, turning that ac load off wont fix the scrambled screen because it doesnt have time based reset written into the code.

I'm sure you have done some strenuous testing and you are correct that neat wiring is the way to fix the problem. I wasnt part of you bulk buy because i was impatient and capable of building and assembling it on my own, I built my own by following the schematics posted by matho and max.

While testing (very sloppy wiring) I had a scrambling problem while only using the element run off the same type of ssr you are using.

So I called Mitch this morning to chat about this, Mitch was really helpful - here's what we talked about (Mitch feel free to correct / clarify anything).

1. Induced voltage generally occurs when you have two sets of cables running parallel - one with high(er) AC voltage. This will induce a voltage an AC voltage in the lower powered cable nearby. The worst situation (from chatting to Mitch - licensed electrician) is when running high current (Amps) for longer runs (>10m). The principles of - keep wires running parallel either shielded or separated is true in any situation, including the Brauduino. Ideally wires should cross at right angles to reduce induction and the shorter the cable, the smaller the effects.

2. The key issue for screen scrambling in the new Brauduino kit is still the pump. Mitch's setup is a little different in that his LCD is further away from the arduino, with wires running through an electrical cabinet, which means the induction for him was in the wires leading to the LCD as both the element cable and the lcd screen cables were running parallel. It was from his heating element only (no pump involved), however, he runs a 5500w element which is higher than most people and therefore more likely to induce AC in the LCD wires. In the Brauduino kit the LCD is connected with PCB headers, which essentially means the induction is almost impossible to happen in this way (the pins are perpendicular to nearly all the wiring).

3. If your wiring is a mess, with long AC cables and long DC cables, you make yourself more susceptible to EMF both from the pump switching and potentially from the heating elements (though seemingly not very likely with 10A elements being used). Tips - same as given before - keep the wiring short as practically possible, push the wiring down and route it at the back of the box as much as possible. Keep it neat and running around the outside of the box, and DC running separately (not parallel) to the AC cabling. Twist the Pump cables going into the board so they look like a helix with a reasonably tight twist and cable tie them together so they won't come undone (the spiralling helps reduce/cancel the emf around the cord). Twisting the AC cables for the elements going from the SSR to the heat outlet sockets would also potentially assist to cancel any emf/induction.

If your wiring is neat and well run, you will likely find your controller working beautifully for a long time without issues

As always - please ask any questions you have and consult with your electrician for verification and advice about anything mentioned here before implementing it.

1. Induced voltage generally occurs when you have two sets of cables running parallel - one with high(er) AC voltage. This will induce a voltage an AC voltage in the lower powered cable nearby. The worst situation (from chatting to Mitch - licensed electrician) is when running high current (Amps) for longer runs (>10m). The principles of - keep wires running parallel either shielded or separated is true in any situation, including the Brauduino. Ideally wires should cross at right angles to reduce induction and the shorter the cable, the smaller the effects.

2. The key issue for screen scrambling in the new Brauduino kit is still the pump. Mitch's setup is a little different in that his LCD is further away from the arduino, with wires running through an electrical cabinet, which means the induction for him was in the wires leading to the LCD as both the element cable and the lcd screen cables were running parallel. It was from his heating element only (no pump involved), however, he runs a 5500w element which is higher than most people and therefore more likely to induce AC in the LCD wires. In the Brauduino kit the LCD is connected with PCB headers, which essentially means the induction is almost impossible to happen in this way (the pins are perpendicular to nearly all the wiring).

3. If your wiring is a mess, with long AC cables and long DC cables, you make yourself more susceptible to EMF both from the pump switching and potentially from the heating elements (though seemingly not very likely with 10A elements being used). Tips - same as given before - keep the wiring short as practically possible, push the wiring down and route it at the back of the box as much as possible. Keep it neat and running around the outside of the box, and DC running separately (not parallel) to the AC cabling. Twist the Pump cables going into the board so they look like a helix with a reasonably tight twist and cable tie them together so they won't come undone (the spiralling helps reduce/cancel the emf around the cord). Twisting the AC cables for the elements going from the SSR to the heat outlet sockets would also potentially assist to cancel any emf/induction.

If your wiring is neat and well run, you will likely find your controller working beautifully for a long time without issues

As always - please ask any questions you have and consult with your electrician for verification and advice about anything mentioned here before implementing it.

nikgr

Member

- Joined

- 10/8/09

- Messages

- 23

- Reaction score

- 0

Hi there .

I am interested on making a controller as such ...

I found on the OpenArdbir site 3 pcb designs

GTO Ardbir Controler

PCB Final

PCB OpnArdbir

Which one should I prefer to develop ?

I can find both Arduino Uno and Nano Boards in my country .Other than that ,are all compatible with initial settings of Ardbir?

If I choose to develop the pcb with the arduino nano how is registered at the initial settings?

Thank you in advance.

I am interested on making a controller as such ...

I found on the OpenArdbir site 3 pcb designs

GTO Ardbir Controler

PCB Final

PCB OpnArdbir

Which one should I prefer to develop ?

I can find both Arduino Uno and Nano Boards in my country .Other than that ,are all compatible with initial settings of Ardbir?

If I choose to develop the pcb with the arduino nano how is registered at the initial settings?

Thank you in advance.

nikgr

Member

- Joined

- 10/8/09

- Messages

- 23

- Reaction score

- 0

Hi if the arduino nano pcb is worth or I would face problems (I've read on the description that may needed a usb programer (why is that?)) and which one of the two other pcb's provided is best for use with the Arduino uno ...

I need to clarify this before starting gathering parts .

I need to clarify this before starting gathering parts .

MaxN68

Well-Known Member

PCB OpenArdbir by DanielXan (bmp file or CAD file) is for Arduino Uno

PCB GTO Controllet by Guto is for Arduino Nano

PCB GTO Controllet by Guto is for Arduino Nano

[email protected]

Member

Hey guys,

I've got a question, however I'm not sure if this is the correct place to ask it.

I've got the Ardbir all-in-one board and have wired it up following the PDF guide supplied by Ardbir. When I turn it on, everything starts up fine, I can go into manual mode and switch on either the heater or the pump and the LEDs on the board come on. However my SSR does not seem to be activated when I turn switch it on. It's like the terminals on the board get no power despite the LED coming on.

Does anyone have any ideas? Any help would be appreciated.

Thanks

Peter

I've got a question, however I'm not sure if this is the correct place to ask it.

I've got the Ardbir all-in-one board and have wired it up following the PDF guide supplied by Ardbir. When I turn it on, everything starts up fine, I can go into manual mode and switch on either the heater or the pump and the LEDs on the board come on. However my SSR does not seem to be activated when I turn switch it on. It's like the terminals on the board get no power despite the LED coming on.

Does anyone have any ideas? Any help would be appreciated.

Thanks

Peter

MastersBrewery

Journeyman, the learning never stops

- Joined

- 7/6/11

- Messages

- 2,319

- Reaction score

- 683

Peter,

I'm not familiar with that particular board, matho's original had the LEDs inline so if they were lit; the on board relay was closed (pump circuit) or there was power to the SSR (heating circuit). Max the poster directly above yours would be able to help you out also a picture of your wiring would be helpful to anyone trying to trouble shoot this. If max hasn't replied in the next day or two send him a pm.

MB

I'm not familiar with that particular board, matho's original had the LEDs inline so if they were lit; the on board relay was closed (pump circuit) or there was power to the SSR (heating circuit). Max the poster directly above yours would be able to help you out also a picture of your wiring would be helpful to anyone trying to trouble shoot this. If max hasn't replied in the next day or two send him a pm.

MB

[email protected]

Member

Hi MB, Thanks for the reply. The wiring for the all-in-one board is pretty simple, you kind of just hook it up to the 12v and then hook up the relay...MastersBrewery said:Peter,

I'm not familiar with that particular board, matho's original had the LEDs inline so if they were lit; the on board relay was closed (pump circuit) or there was power to the SSR (heating circuit). Max the poster directly above yours would be able to help you out also a picture of your wiring would be helpful to anyone trying to trouble shoot this. If max hasn't replied in the next day or two send him a pm.

MB

Here's the image provided by ardbir.

https://s3.amazonaws.com/images.ecwid.com/images/6605042/306558246.jpg

Hopefully I'll hear from Max.

MastersBrewery

Journeyman, the learning never stops

- Joined

- 7/6/11

- Messages

- 2,319

- Reaction score

- 683

ok so circuits look the same/similar; if the LED is lit the Relay out puts should have power, insure you have the board wired to the DC side of the relay, once again a quality pic of your work would be helpful.

Ed: Just a thought you do realise the high voltage side of the relay is just a switch; usually put on the path of the active 240v

Ed: Just a thought you do realise the high voltage side of the relay is just a switch; usually put on the path of the active 240v

[email protected]

Member

Thanks, I understand how the relays work, I built a fermentation chamber with the brewpi system that switches a heater and fridge using similar SSRs.MastersBrewery said:ok so circuits look the same/similar; if the LED is lit the Relay out puts should have power, insure you have the board wired to the DC side of the relay, once again a quality pic of your work would be helpful.

Ed: Just a thought you do realise the high voltage side of the relay is just a switch; usually put on the path of the active 240v

I can take a pic of my specific wiring when I get home tonight, I'll also double check the output with my meter to make see if there is actually any output coming out or if my heater relays or 12v pump are dead, but it seems unlikely to me that they both would be.

On the curcuits, one thing I notice is that the bus to the LED seems to run in parallel with the bus to the transistor. Is it possible that the transistor, diode or resistors are damaged and so the LED lights up but the circuit breaks down there?

[email protected]

Member

Thanks, yes I get that, but the other relay doesn't work either, nor if I connect my 12v pump directly to the ardbir board as I've read other people do.heffa35 said:Peter, the picture provided by Ardbir has an error. The pump relay is wrong. It illustrates connection form the board and into the 'load' side.

Make sure you connect both the pump relay/SSR to the IN - DC connectors.

MastersBrewery

Journeyman, the learning never stops

- Joined

- 7/6/11

- Messages

- 2,319

- Reaction score

- 683

ok just to make sure all is good I'll post up matho's destructions page 17 is the diagram you want to check out just note his board has a relay onboard for the pump so you will need to wire that through, actually I'd be more inclined to use 2 SSR's but thats just me

View attachment brauduino controller build1.pdf

View attachment brauduino controller build1.pdf

[email protected]

Member

OK, so I broke out the multimeter, when I have the "pump off" I get 11v over the pump terminals, of I have the "pump on" I get 10v over the pump terminals. Both "heat off" and "heat on" give me 0.01v over the heat terminals. This sounds like the transistors are dead?

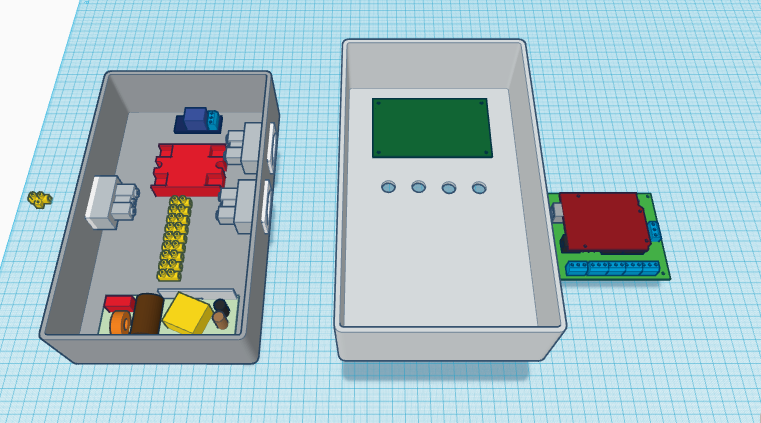

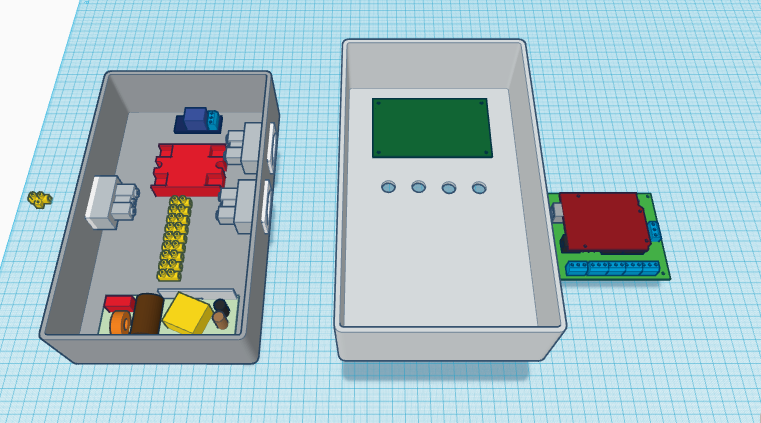

Hi guys, here the status of my controller:

PCB mounted and Ardbir running, I made a 3D sketch, feel free to use: https://www.tinkercad.com/things/5at4r51bbMd-caixa

PCB mounted and Ardbir running, I made a 3D sketch, feel free to use: https://www.tinkercad.com/things/5at4r51bbMd-caixa

NealK

Well-Known Member

- Joined

- 28/2/12

- Messages

- 400

- Reaction score

- 150

I have been using my original control box for about 18 months now and run the latest version of ArdBir. I use the original kit that was a board that I had to solder together myself and it has worked brilliantly for the last year and a half.

I had to do a talk today at my brew club (Westgate Brewers) on how to build your own Braumeister type brewery. Everything went pretty well until I opened up the control box. I haven't opened it for a few months and was pretty shocked when I saw what has happened to my SSR.

I have a 3kw Birko 40l urn and did upgrade the mains connectors to be 20 amp. I very surprised to see how badly cooked the ssr is. A new is on its way from ebay but I think I will have to add some extra cooling to the heatsink when I fit the new ssr.

Has anybody else had a similar issue?

I had to do a talk today at my brew club (Westgate Brewers) on how to build your own Braumeister type brewery. Everything went pretty well until I opened up the control box. I haven't opened it for a few months and was pretty shocked when I saw what has happened to my SSR.

I have a 3kw Birko 40l urn and did upgrade the mains connectors to be 20 amp. I very surprised to see how badly cooked the ssr is. A new is on its way from ebay but I think I will have to add some extra cooling to the heatsink when I fit the new ssr.

Has anybody else had a similar issue?

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 13

- Views

- 5K

- Replies

- 12

- Views

- 4K

- Replies

- 11

- Views

- 6K