Same with software skills & electronics skills. I personally would recommend against using a windoze PC or PC at all. I don't really like PIC micros either. You need practically no CPU power to do this job. It's all about I/O. Go get some audinos. I used the same AVR cpu in the brewbot can really like the lib-arv and gcc toolchain for it. Alternatively look at a cheap ARM based board. Plenty of CPU grunt in any ARM. Can even get one that runs a full OS (linux).

**** it, if zizzle is going to make some effort so will I.

just about everything you want to achieve has been done using the brewtroller.

http://www.brewtroller.com/wiki/doku.php

Take a breather read though the brewtroller forum, ask some questions over there.

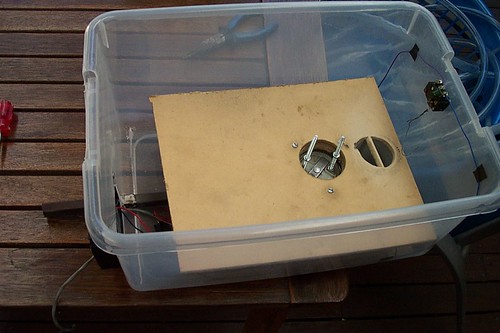

I have used the brewtoller to build an automated brewbot. about the only thing that hasn't been implemented in a code release is automated grain delivery, but I know there are threads on it. I used to have automated grain delivery on a previous brewbot, but it really is not necessary for mycurrent setup. Mine was basically a hopper prefilled with the grain bill, feeding the motorised mill with a shute leading into the mash tun. the motor was started on a timer. so I could prefill the hopper and have it fire up in the wee hours. My old system was discrete hardware based on auberins PIDS, but the more I developed it the more I needed a top level controller and a lot of the interlocks and safety could be handled a hell of a lot easier with a uc.

You will find a broad mix of people over there from code cutters, engineers to fabricators. The code is open source, actively developed and uses the Sanguino. They have just updated to 128KB uc. You will find source code with compile time options to suit your system and you can purchase bargain hardware through the project as well.

In my opinion, one of the most important things to come from Zizzle and I'll second it, is to start putting something together, brew with it, write down all the things you want handled differently or developed

and make some modifications, brew again and so on. take off small chunks, do things manually, then think, now how best can I automate that.

I'll back that up with a heavy dose of listen to Lethal. a lot of what you have posted is bloody dangerous and downright stupid. playing with automation is a very different skillset to making sure you don't over heat anything, wiring, GPO etc and burn the place down.

Brewing in a laundry owned by someone else is a bad idea, brewdays, no matter how careful you are, can be messy. You mentioned a shed in one of your posts, go down that path, you won't regret it. come cleanup you can throw water around and do the job properly. mount your brewery on some wheels, so you can wheel it outside to cleandown.

I completely understand your need to tinker, but do it small chunks.

I have been developing my brewery over 5 or so years, I like to tinker and make mods. I have completely rebuilt it twice.

don't spend too much time getting everything perfect the first time around, chances are you will modify it at sometime. ie welding, make solid strong welds, but don't spend time making them pretty, just make them work.