I took my sweet time in responding so I missed the comments before.

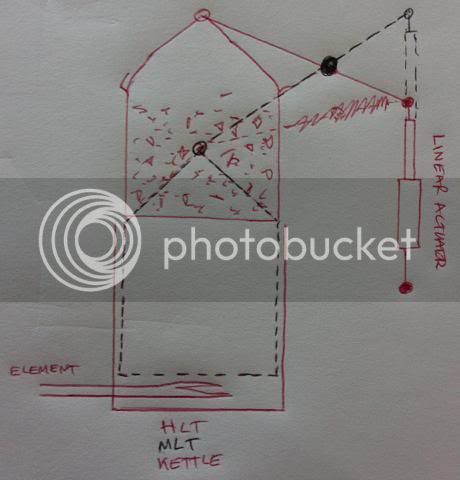

Can you share, what were some of your ideas towards that route? I have a few ideas up my sleeve, some of which were spoken about in another thread in the gear section. Basically looking towards a set & forget four-hour duration. Load grain, water and hop hoppers, push a big red button and go back to bed. An alarm goes off that tells me I need to transfer boiling wort to a cube, then I clean the gear up, and that's another brew-day done. I can spend more time cultivating big healthy starters instead.

/quote]

Just wrote a reply, but it got lost - site has changed - anyone else see the OP at the top of each page?

Anyway, attached pic should be pretty self explanetery. ask if it need some more explanation.