I BIAB + no-chill in a 37L Aluminium crab cooker with a 3-ring burner. I have been focusing on things like fermentation control and (basic) yeast management so far, but i'm looking at what I can do to improve my brew day.

After getting sick of siphoning I have got the parts to add a ball valve to the pot. Assuming I don't stuff that up, I'm thinking of what might be next with my equipment. My main concern right now is temp control and the attention required during temp adjustments (strike temp, step mash, and mash out) with the constant stirring and checking temps.

I don't plan on going bigger volume as that would necessitate a pot and burner replacement and also be hard to justify with the minister. My current two thoughts are a grain mill, or a diy herms setup.

I currently crack my grain in the thermomix. 300gm batches for 3-5s ends up pretty flour-y with some husks sill visible. I am not too unhappy with with outcome. My main concerns with this method is the noise. I'm getting ~70-75% mash efficiency, but losing quite a lot due to trub (presumably from the flour). I would hope that a mill would help (a bit) with the consistency and trub loss, bit i'm not all that unhappy using the thermomix as it stands.

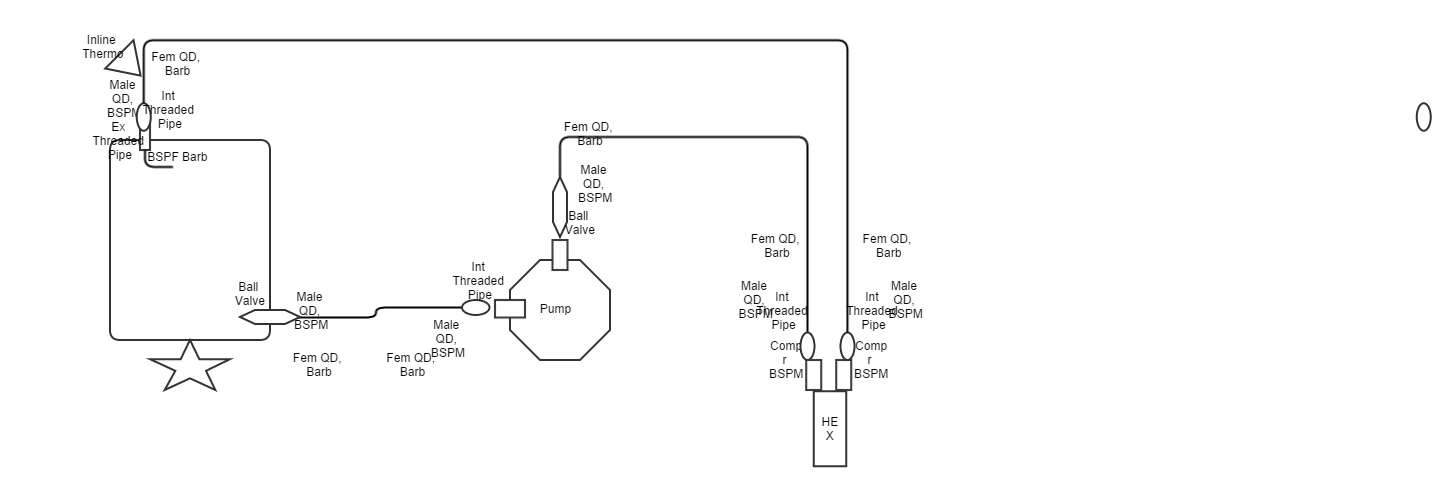

The other option would be looking at adding a herms setup using a 19L bigw pot, 3m copper coil, and a kaixin pump (maybe a little brown pump). The key thing I would like from this would be temp consistency in the mash, step mashing control, and a bit more automation of the temps (instead of having to stir and monitor during ramps). If I took the 'herms' part out of this and just had recirculation and some gas control it might be sufficient for at least getting more consistent temps through the mash.

All up it seems a recirculating (non herms) setup would be on par with a mill in terms of price @ $150-200, with the herms part able to be added in later. One key factor in my thinking is that without a grain mill I may be stuffed regarding stuck recirculation\sparges with any future upgrades I might make. It also seems the recirculation might just be more effort than its worth, in which case I would then question whether a mill is necessary.

I could just stick with the status quo until I get a better idea of where my process is struggling, but that seems boring

Sorry, that ended up pretty long-winded, but any thoughts would be appreciated.

After getting sick of siphoning I have got the parts to add a ball valve to the pot. Assuming I don't stuff that up, I'm thinking of what might be next with my equipment. My main concern right now is temp control and the attention required during temp adjustments (strike temp, step mash, and mash out) with the constant stirring and checking temps.

I don't plan on going bigger volume as that would necessitate a pot and burner replacement and also be hard to justify with the minister. My current two thoughts are a grain mill, or a diy herms setup.

I currently crack my grain in the thermomix. 300gm batches for 3-5s ends up pretty flour-y with some husks sill visible. I am not too unhappy with with outcome. My main concerns with this method is the noise. I'm getting ~70-75% mash efficiency, but losing quite a lot due to trub (presumably from the flour). I would hope that a mill would help (a bit) with the consistency and trub loss, bit i'm not all that unhappy using the thermomix as it stands.

The other option would be looking at adding a herms setup using a 19L bigw pot, 3m copper coil, and a kaixin pump (maybe a little brown pump). The key thing I would like from this would be temp consistency in the mash, step mashing control, and a bit more automation of the temps (instead of having to stir and monitor during ramps). If I took the 'herms' part out of this and just had recirculation and some gas control it might be sufficient for at least getting more consistent temps through the mash.

All up it seems a recirculating (non herms) setup would be on par with a mill in terms of price @ $150-200, with the herms part able to be added in later. One key factor in my thinking is that without a grain mill I may be stuffed regarding stuck recirculation\sparges with any future upgrades I might make. It also seems the recirculation might just be more effort than its worth, in which case I would then question whether a mill is necessary.

I could just stick with the status quo until I get a better idea of where my process is struggling, but that seems boring

Sorry, that ended up pretty long-winded, but any thoughts would be appreciated.