Crusty

Well-Known Member

Hi guys,

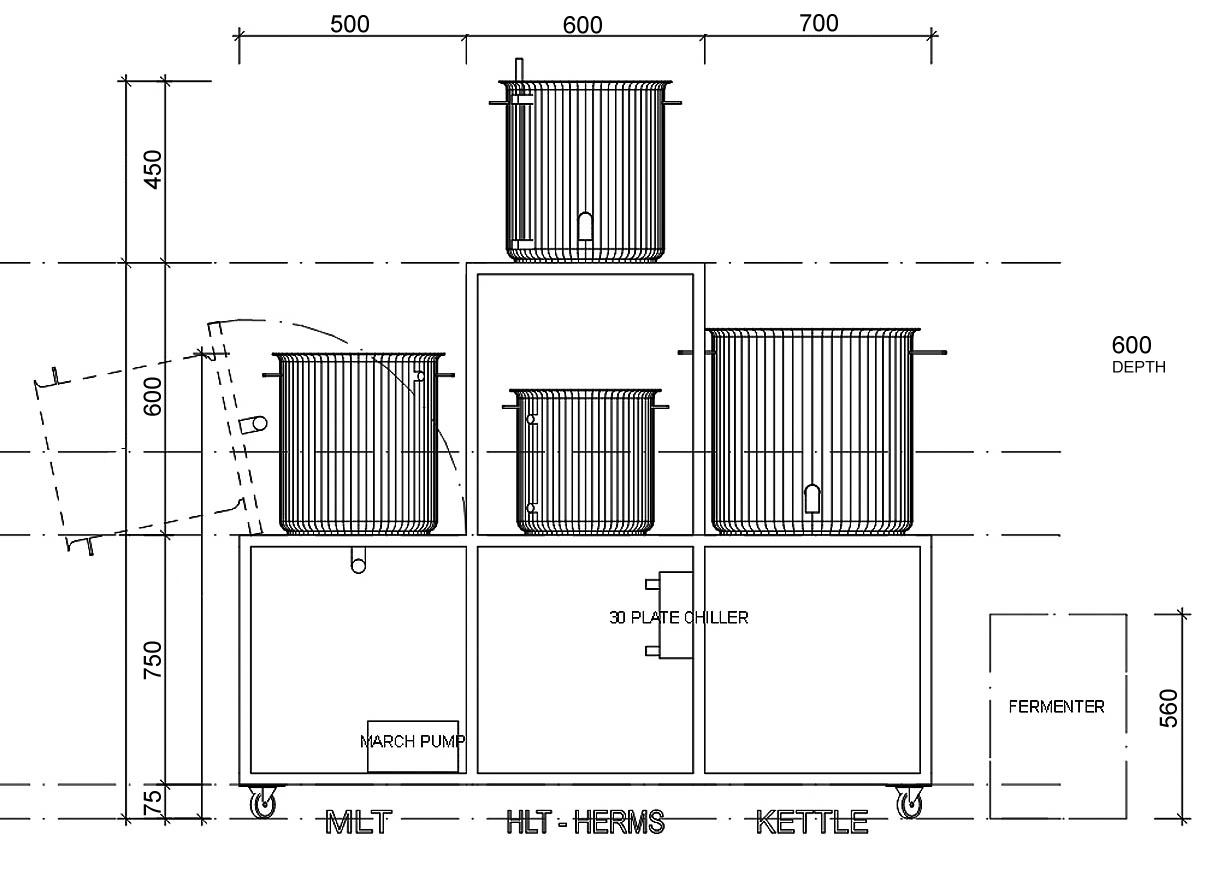

I am using tall keggles for my brewery ( 600mm high ) & looking for some ideas on brew stand height.

My castors are 150mm high to where they will be mounted & am looking at an overall stand height of 600mm, with castors ( 1200mm total height with kegs )

This allows me to look over & into my vessels without tiptoeing or straining to look down into the vessels.

Can some of you guys give me an idea of your brew stand measurements, bottom of stand to top of stand, forgetting the influence of castors.

Cheers

I am using tall keggles for my brewery ( 600mm high ) & looking for some ideas on brew stand height.

My castors are 150mm high to where they will be mounted & am looking at an overall stand height of 600mm, with castors ( 1200mm total height with kegs )

This allows me to look over & into my vessels without tiptoeing or straining to look down into the vessels.

Can some of you guys give me an idea of your brew stand measurements, bottom of stand to top of stand, forgetting the influence of castors.

Cheers